Solar module box

A technology of solar energy and modules, which is applied in the direction of semiconductor devices, photovoltaic power generation, sustainable manufacturing/processing, etc., can solve the problems that affect the service life of power generation modules, the module box is easy to break, and the manufacturing process is complicated, so as to achieve easy molding , not easy to crack and wrinkle, good structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

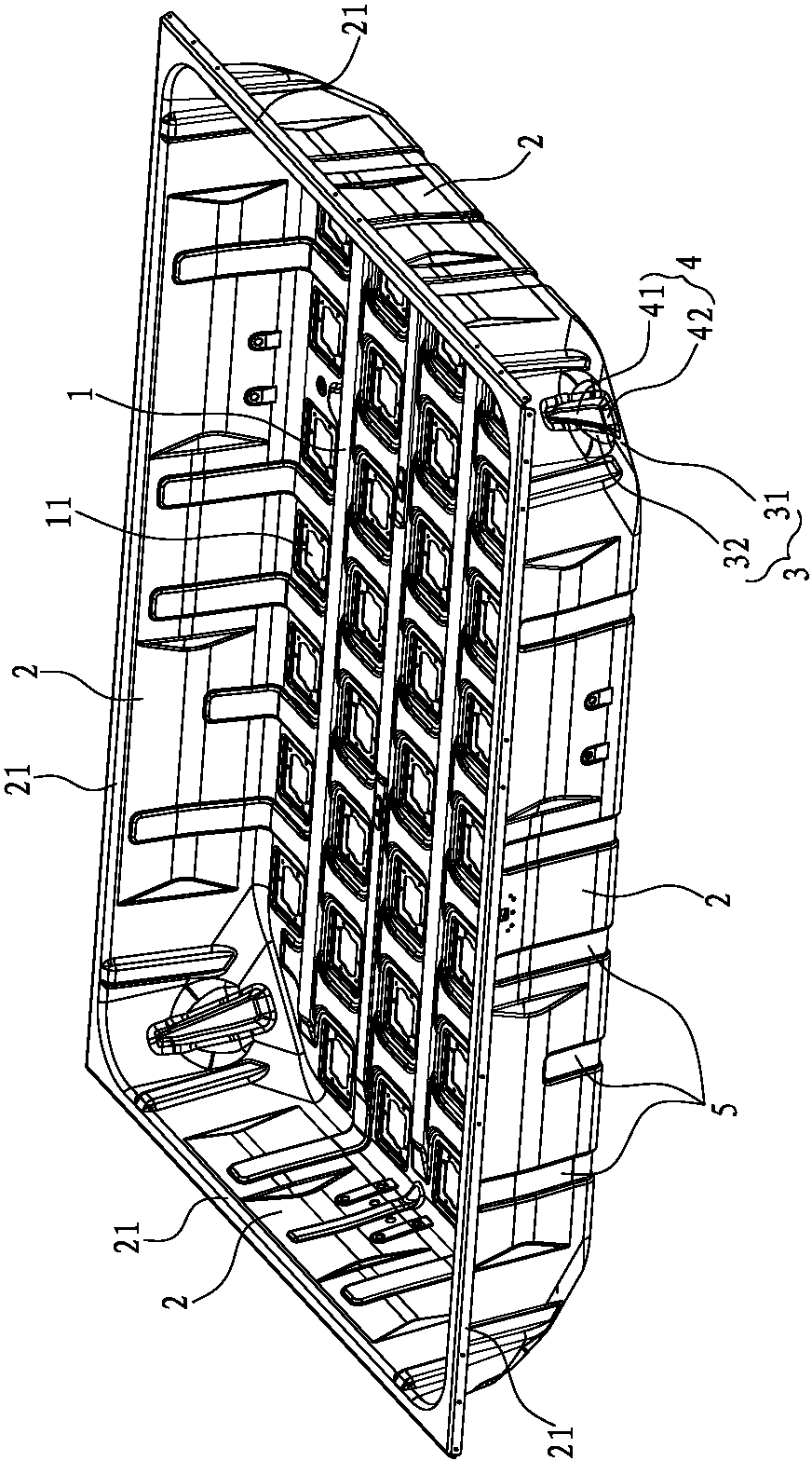

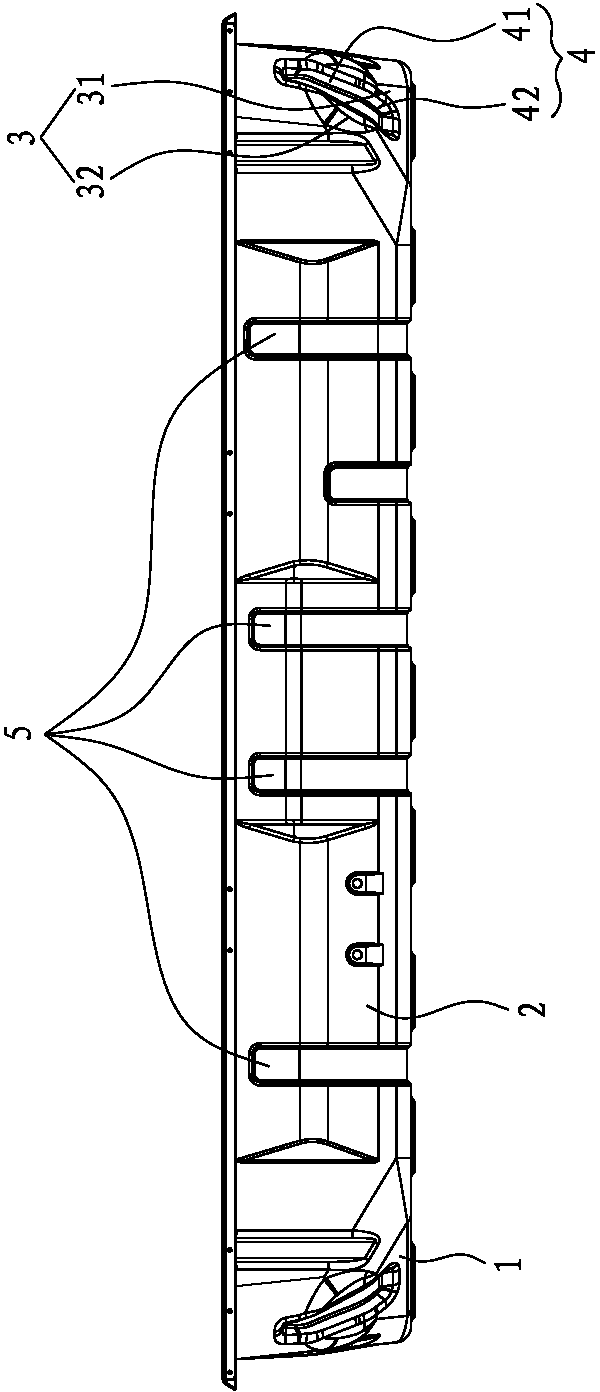

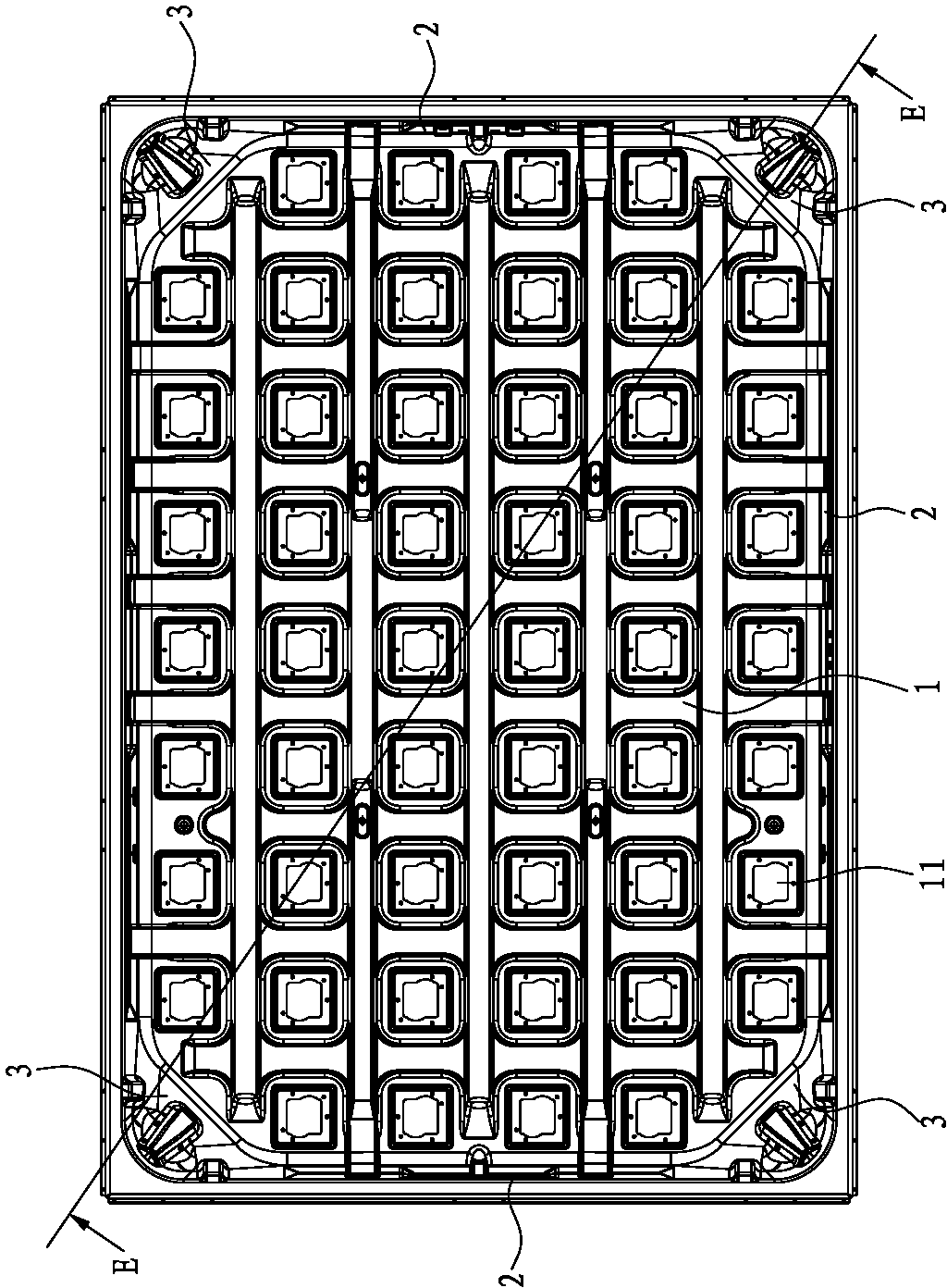

[0021] Such as figure 1 , figure 2 As shown, the present invention is a solar module box, which is integrally formed of metal materials, and has a bottom plate 1 and side plates 2 located on four sides of the bottom plate 1 . The bottom plate 1 is rectangular, and is provided with a plurality of through-holes 11 for placing receiver components. The lower edges of the two side plates 2 and the joint surface of the bottom plate 1 form corners 3, and there are four corners 3 in total. The corner 3 is a slope 3 .

[0022] The inclined surface 3 is composed of two sections of small inclined surfaces 31 and 32 that are inclined from top to bottom and inwards in sequence. It should be noted that the slope 3 can also be composed of two or more small slopes that incline from top to bottom and inward in turn, and the angle of each small slope decreases from the bottom plate 1 upwards. The included angle is greater than 90°. refer to Figure 3-Figure 6 As shown, in this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com