An intelligent design method for low-carbon and lightweight equipment rotary table

A rotary table, intelligent design technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of increasing manufacturing costs, material potential can not be fully utilized, and the performance of rotary table is difficult to improve, etc., to achieve The effect of improving design efficiency, high specific stiffness, low carbon and lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

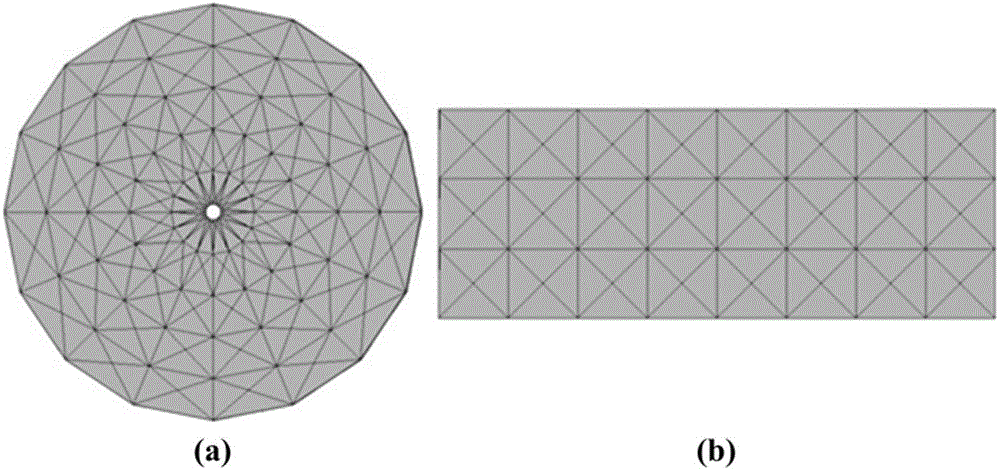

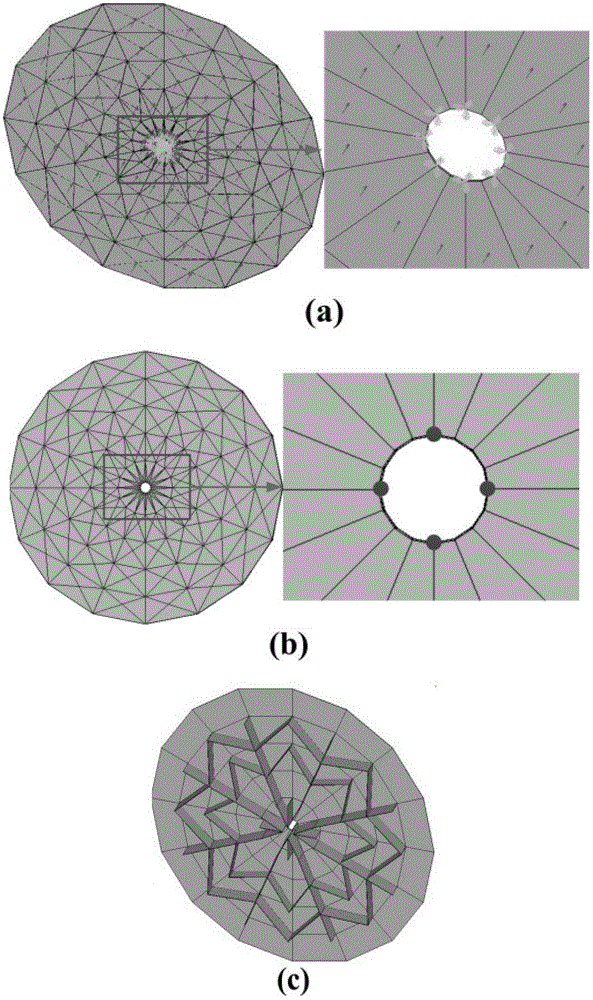

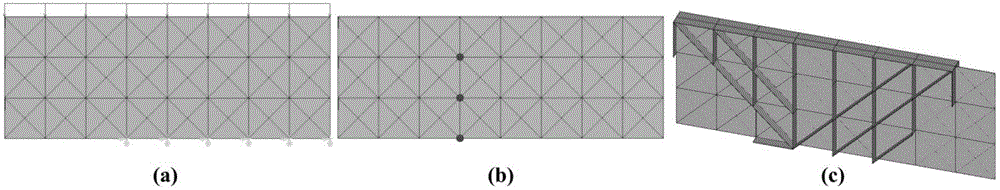

[0036]The present invention aims to provide a low-carbon and lightweight design scheme for the equipment rotary table structure based on the load-bearing configuration intelligent creation criterion. The design result is clearer than the traditional topology optimization result, and can directly provide a solution for the actual engineering design. support. The design scheme of the present invention first divides the equipment rotary table into two parts, the table support part and the side support part, according to the difference in load-bearing function. Applying the intelligent generation criterion of load-bearing configuration to these two parts, the structural design problem of the rotary table is transformed into the intelligent generation problem of the rib configuration of the table support part and the side support part:

[0037] 1. Pre-processing: According to the different bearing functions, the rotary table is divided into the main load application part, called th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com