Spectral electrolytic cell suitable for in-situ characterization of Raman spectrum

A Raman spectroscopy and electrolytic cell technology, which is applied in the field of spectral electrolytic cells to achieve the effects of easy operation, uniform power lines, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

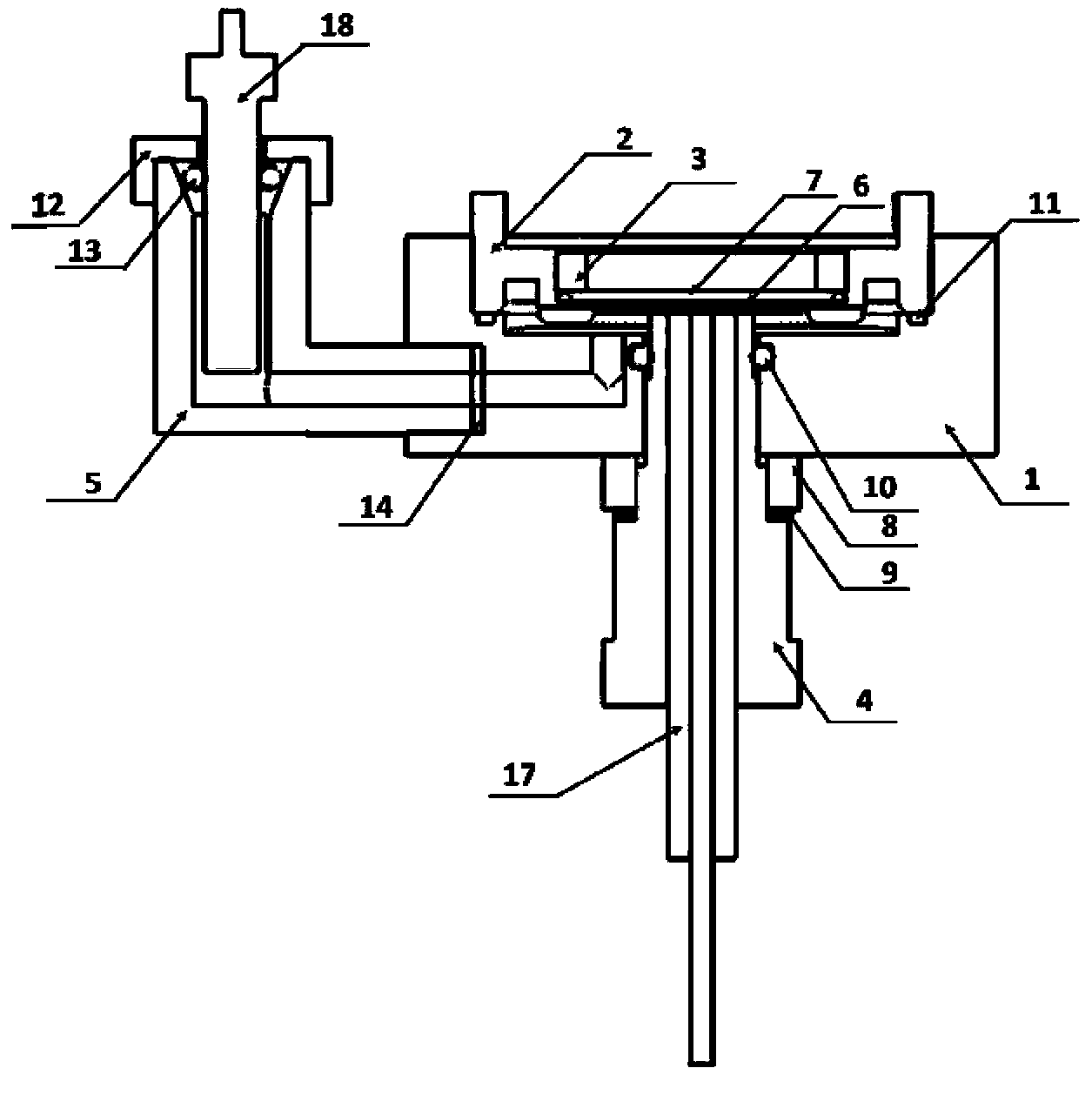

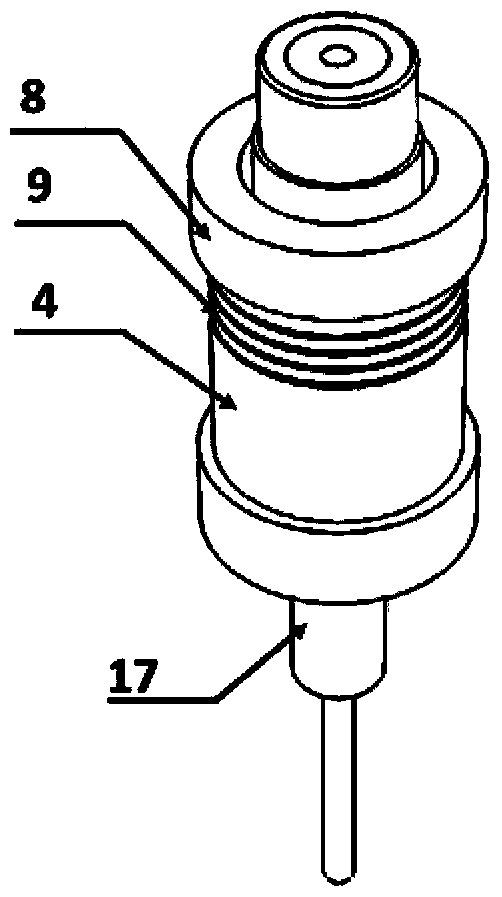

[0031] Such as Figure 1-7 As shown, the embodiment of the present invention is provided with a spectral electrolytic cell body 1, a spectral electrolytic cell top cover 2, a window sealing ring 3, an electrode sleeve 4, a reference electrode connection end 5, a spectral window 6, an O-ring 7, Limit ring 8, limit adjustment gasket 9, O-ring 10, sealing gasket 11, reference electrode sealing cover 12, O-ring 13, sealing gasket 14, counter electrode lead 15, counter electrode 16, working electrode 17. Reference electrode 18.

[0032] The spectral electrolytic cell body 1 is connected to the spectral electrolytic cell top cover 2, and the window sealing ring 3 is fixed on the spectral electrolytic cell top cover 2; the middle position of the spectral electrolytic cell body 1 is provided with a first hole 1-1 , the electrode cover 4 is located in the first hole 1-1, the first hole 1-1 is provided with a groove for placing the O-ring 10, and the sealing is realized by the contact ...

Embodiment 2

[0050] This embodiment is a further illustration of placing an O-ring at the through-hole groove in the middle of the cell body in Example 1 to realize the sealing between the cell body and the working electrode. The O-ring is not limited to a circular sealing ring and can be various Gaskets of various shapes and materials.

Embodiment 3

[0052] This embodiment is a further description of placing an O-ring at the through-hole groove in the middle of the cell body in Example 1 to realize the sealing between the cell body and the working electrode. The sealing ring seal is only a mode of this design, and it can also be threaded or sealed by a tight fit. A combination of these sealing methods is also possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com