Muddy water balance push bench

A mud-water balance and pipe jacking technology, which is applied to mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/fittings, etc. It can solve problems such as low slag discharge efficiency, complex structural design, and inability to control land subsidence well. , to achieve the effect of good working environment, safe operation and small ground subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

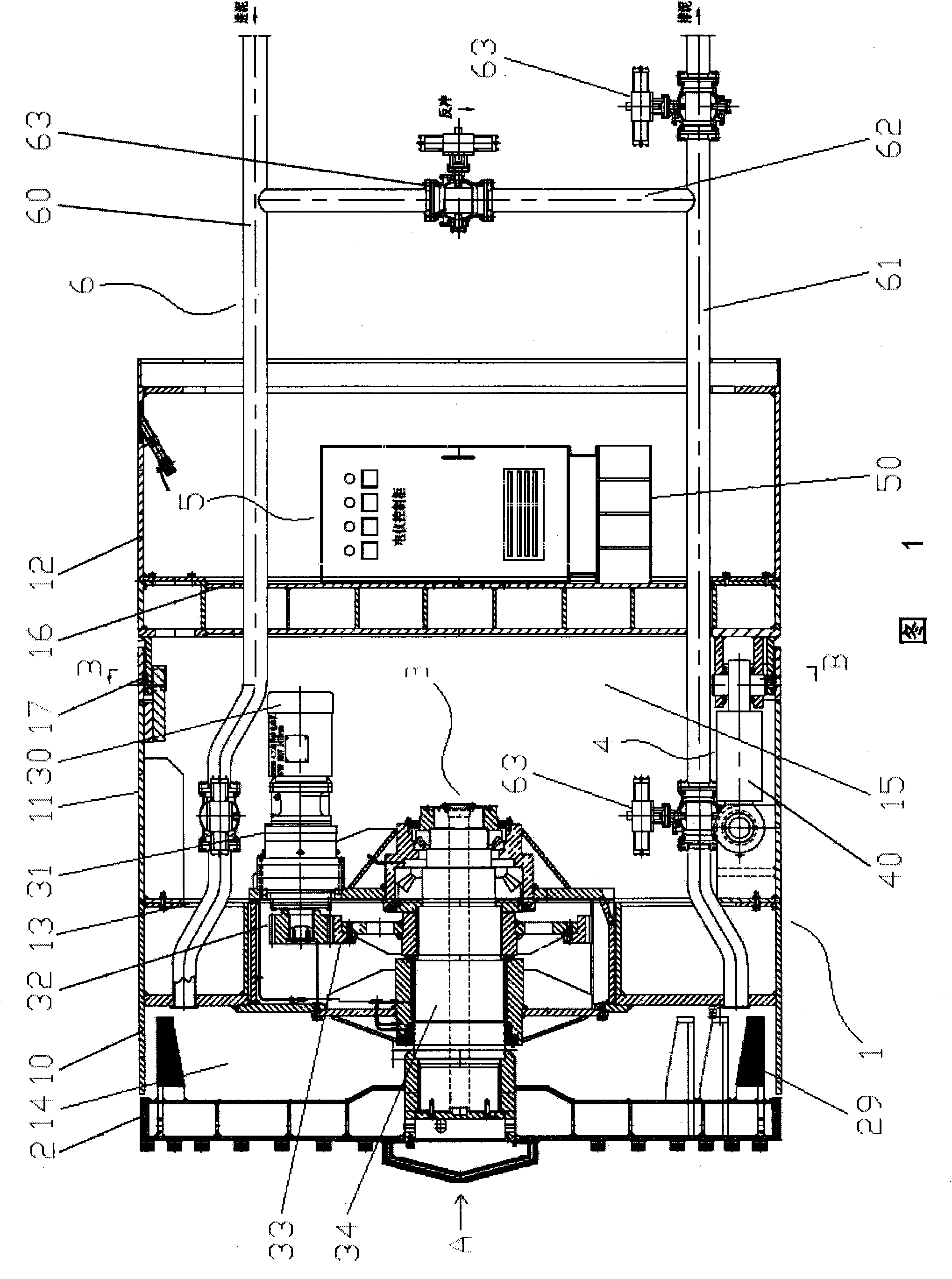

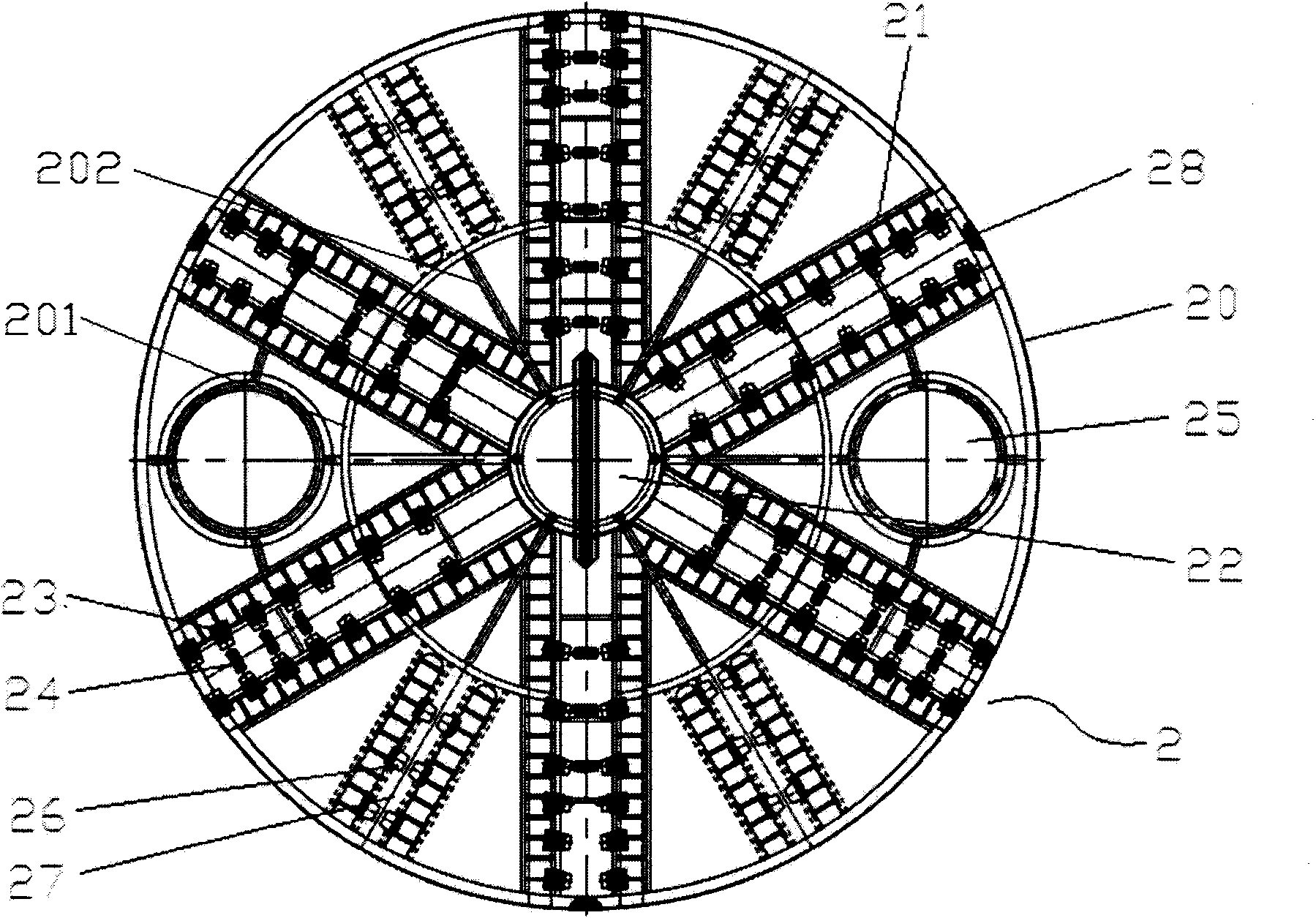

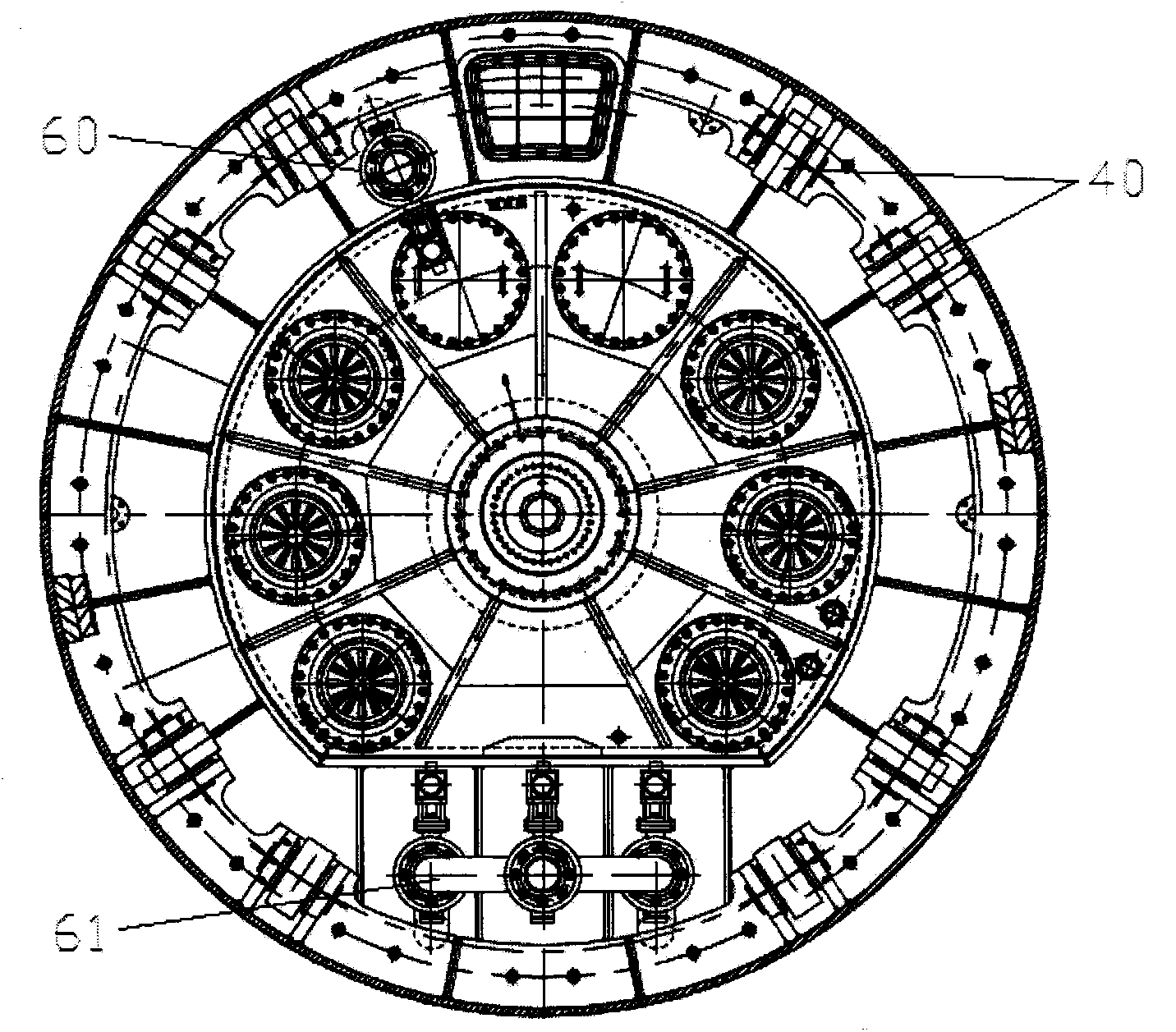

[0036] figure 1 The muddy water balance pipe jacking machine 100 provided according to the present invention is shown, and the muddy water balance pipe jacking machine 100 comprises a cylindrical casing 1, a cutting cutter head 2, a cutter head driving unit 3, a hinge unit 4, an electrical instrument control unit 5 and a mud conveying and Cycle unit 6.

[0037] Among them, the cylindrical shell 1 is a steel structure, which is used for accommodating and supporting the cutter head driving unit 3 , the hinge unit 4 , the electrical instrument control unit 5 and the mud conveying and circulation unit 6 . In this embodiment, the cylindrical casing 1 includes a front-section casing 10 , a middle-section casing 11 and a rear-section casing 12 . The front shell 10 and the middle shell 11 are welded into one body, and the rear shell 12 is hinged to the rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com