Intelligent fermentation leaven room

A kind of bending room and intelligent technology, applied in the field of brewing equipment, can solve the problems of poor working environment, high labor intensity, low production efficiency, etc., and achieve the effect of guaranteeing the quality of koji, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

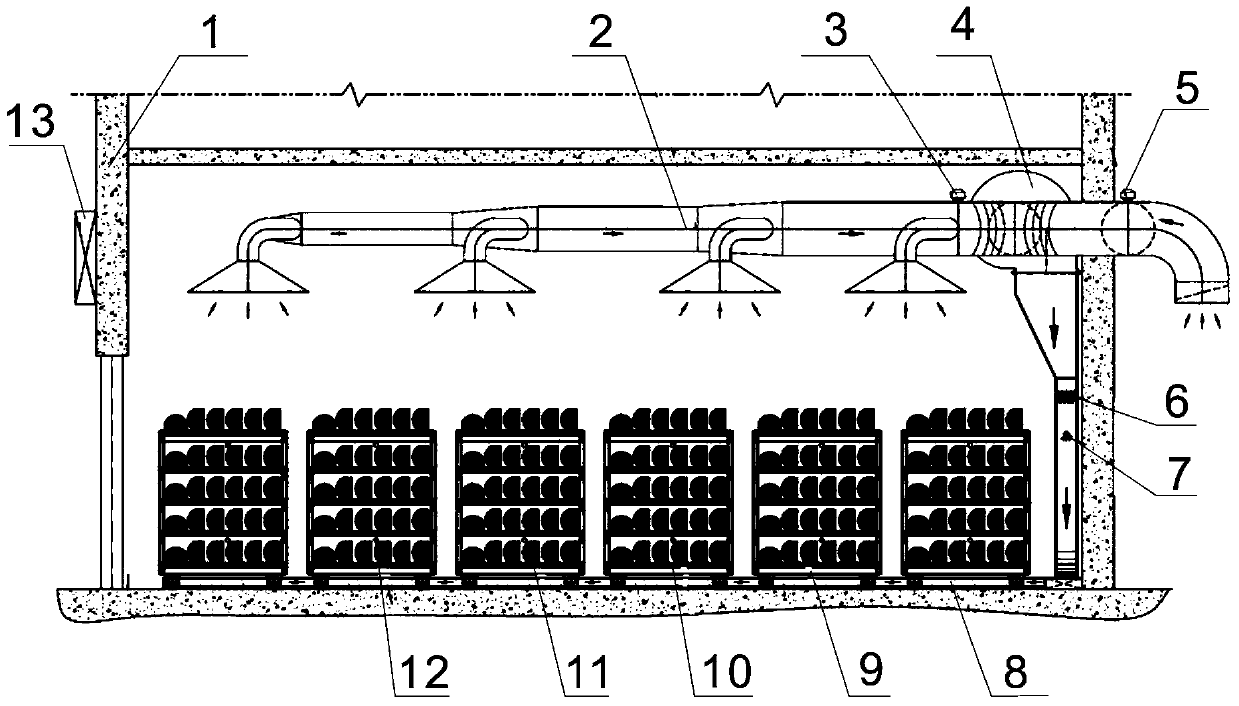

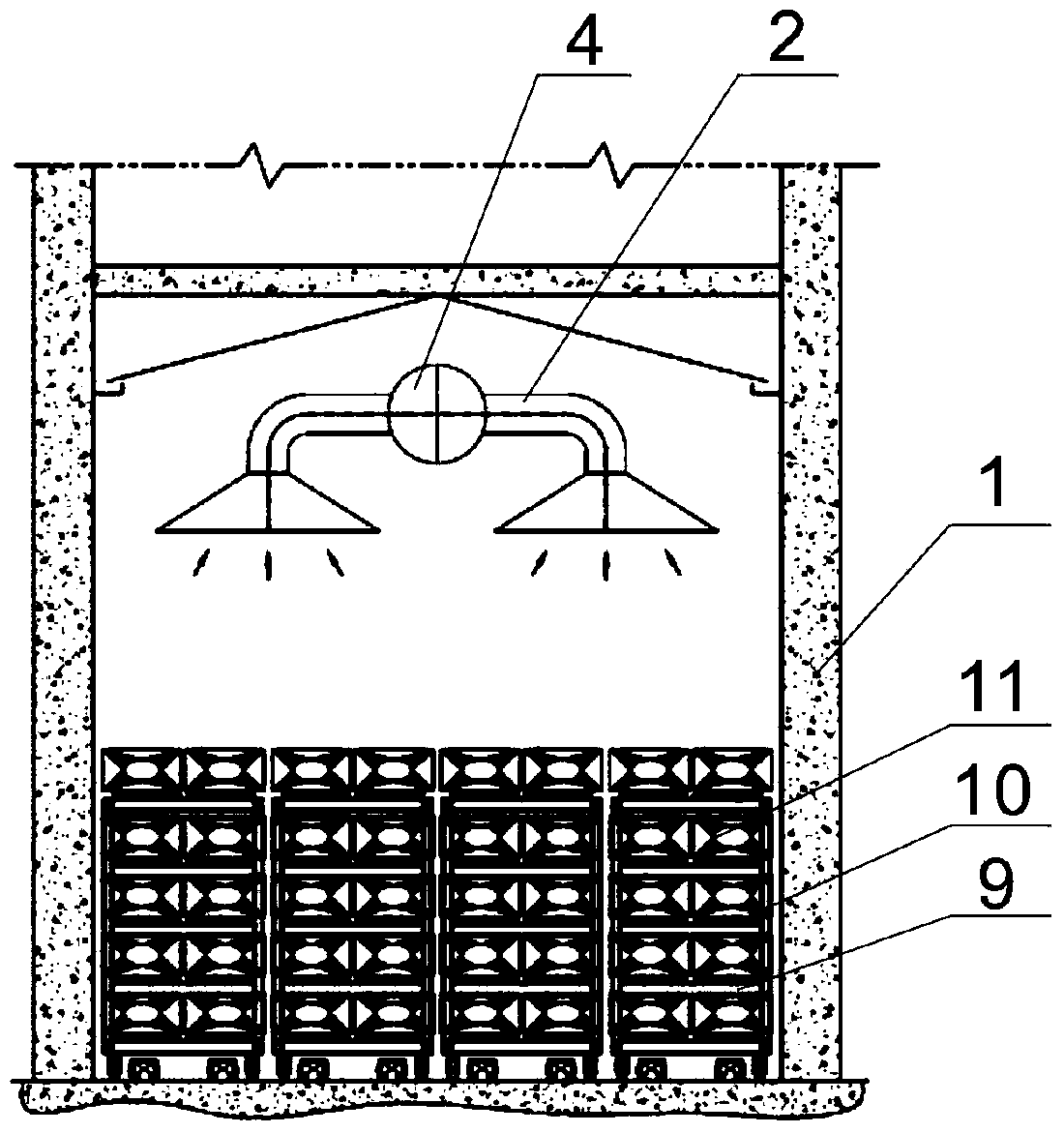

[0020] Such as figure 1 , figure 2 As shown, a kind of intelligent fermentation room according to the present invention includes a music room body 1, an air-regulating blower 4, an air-regulating blower pipe 8, an air-regulating exhaust pipe 2, a mobile shelf 9 and is arranged on the music room body 1 The external control system 13, the air-regulating blower pipe 8, the air-regulating blower 4, and the air-regulating exhaust pipe 2 are connected in series inside the curved room body 1, so that the air can be evenly blown into the curved room and uniformly exhausted. Both sides of the air-regulating blower 4 are respectively provided with a control valve A3 and a control valve B5, and the mobile shelf 9 is arranged in the curved room body 1, and a plurality of bamboo rafts 10 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com