Large-span floor slab reinforcing method

A floor slab and polyethylene board technology, applied in building maintenance, construction, building construction, etc., can solve problems such as stress loss, high frictional resistance, poor tensioning effect of prestressed tendons, etc., to reduce stress loss and reduce friction The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

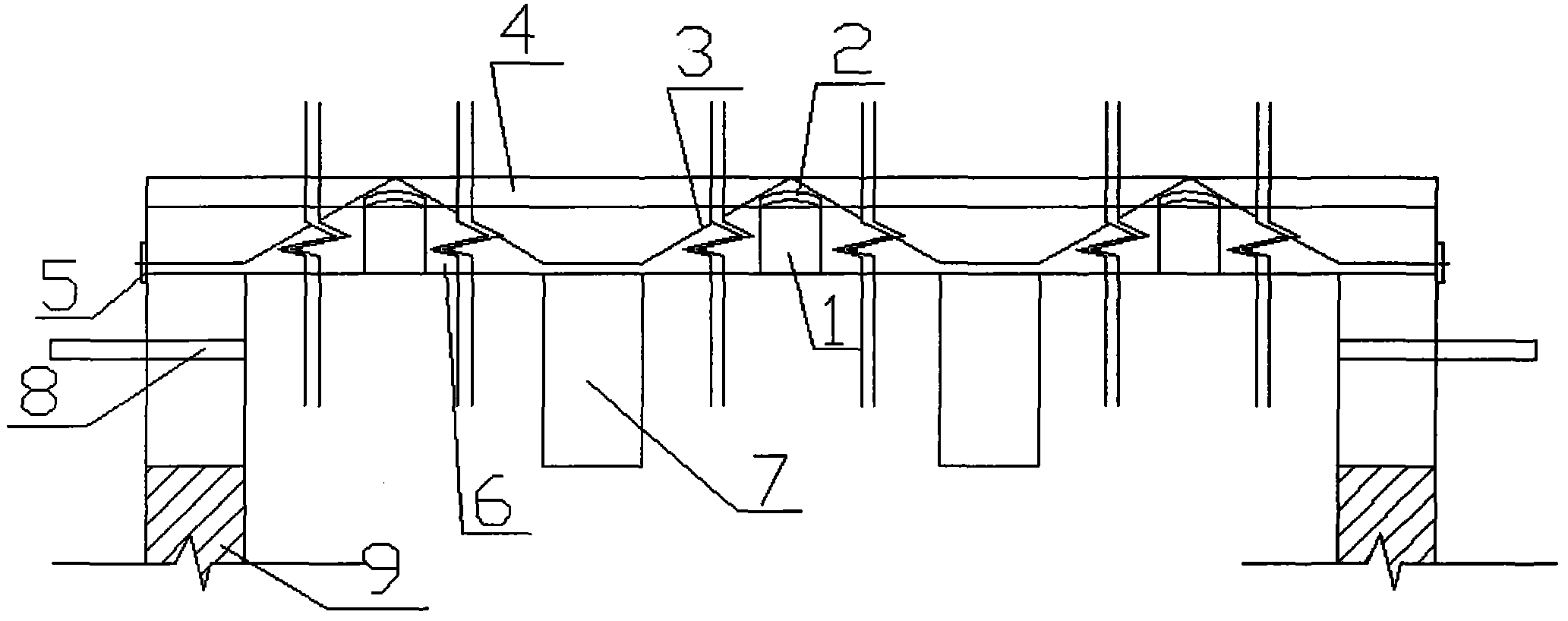

[0020] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0021] figure 1 It is a schematic diagram of the reinforcement structure of a long-span floor. In this embodiment, a diverter 1 is arranged in the middle of the concrete floor 6 between the wall 9 and the concrete beam 7, and a diverter 1 is arranged in the middle of the concrete floor 6 between the concrete beam 7 and the concrete beam 7, and a polyethylene plate is pasted on the top of the diverter 1. 2. The thickness of the polyethylene board 2 is 4 mm, and the top surface of the polyethylene board 2 is made into an arc with a radius of 550 mm. The top of the steering gear 1 is provided with a polyethylene plate 2, and the prestressed tendons 3 in the concrete floor 6 are distributed in a folded shape. The diameter of the prestressed tendons 3 is 14mm. A high-strength plastic sleeve is embedded inside. The diameter of the high-strength plastic sleeve is 35-40 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com