Refining device and process for casting die-cast aluminum products

A product, cast aluminum technology, applied in the field of casting die-cast aluminum product refining equipment, can solve the problems of poor refining effect, secondary hydrogen absorption and oxidation of aluminum liquid, etc., achieve the effects of reducing crucible loss, high hydrogen removal rate, and avoiding direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

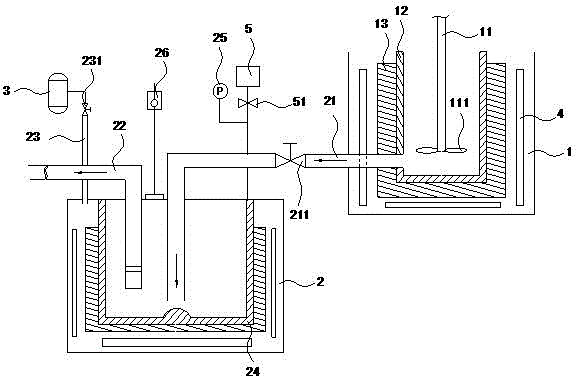

[0033] Such as figure 1 As shown, a refining device for casting aluminum products includes a melting furnace 1 and a closed holding furnace 2. The melting furnace 1 is provided with a lifting stirring shaft 11 and a stirring blade 111 sleeved on the stirring shaft 11. The shaft 11 is provided with a middle through hole for introducing inert gas, the melting furnace 1 is connected to the closed holding furnace 2 through a feed pipe 21, the holding furnace 2 is provided with a drain pipe 22, and the refining device also A vacuum pump 3 is included, and the holding furnace is connected to the vacuum pump 3 through a vacuum pipe 23.

[0034] The melting furnace 1 can be located at the height of the closed holding furnace 2 to increase the potential energy of the molten aluminum. The stirring shaft 11 can be raised and lowered. It is initially located above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com