Graphene oxide fiber, preparation method, and preparation method of graphene oxide fiber composite material

A graphene fiber and graphene fiber technology, applied in the field of graphene, can solve the problems of limited application and large diameter of graphene fibers, and achieve the effect of improving tensile strength and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

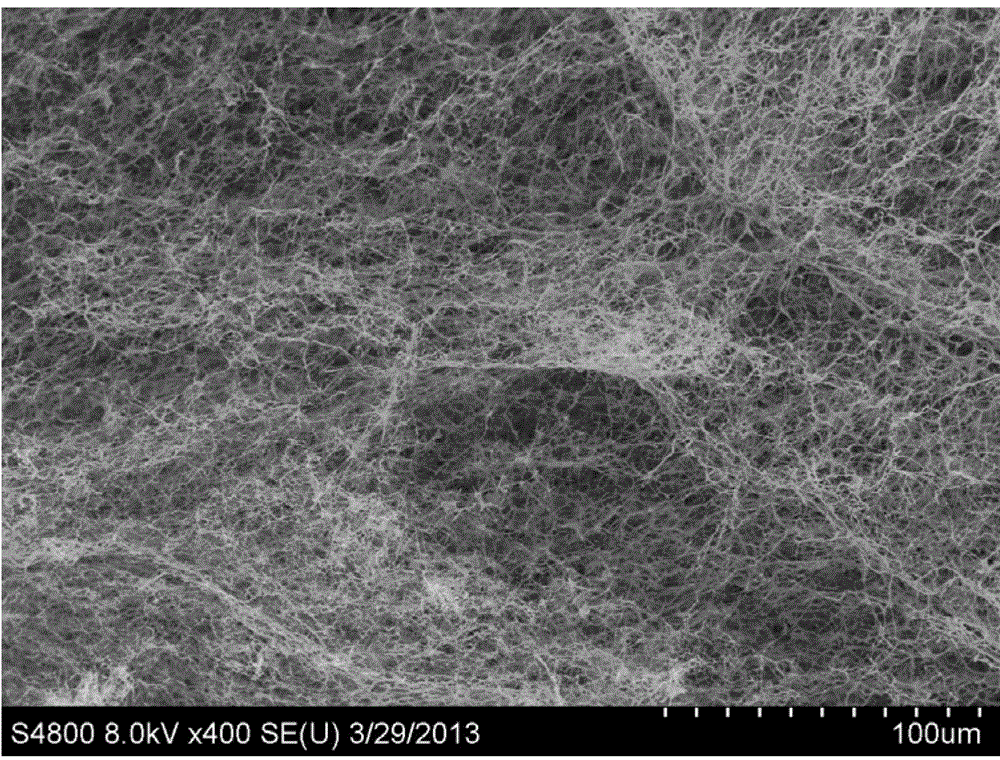

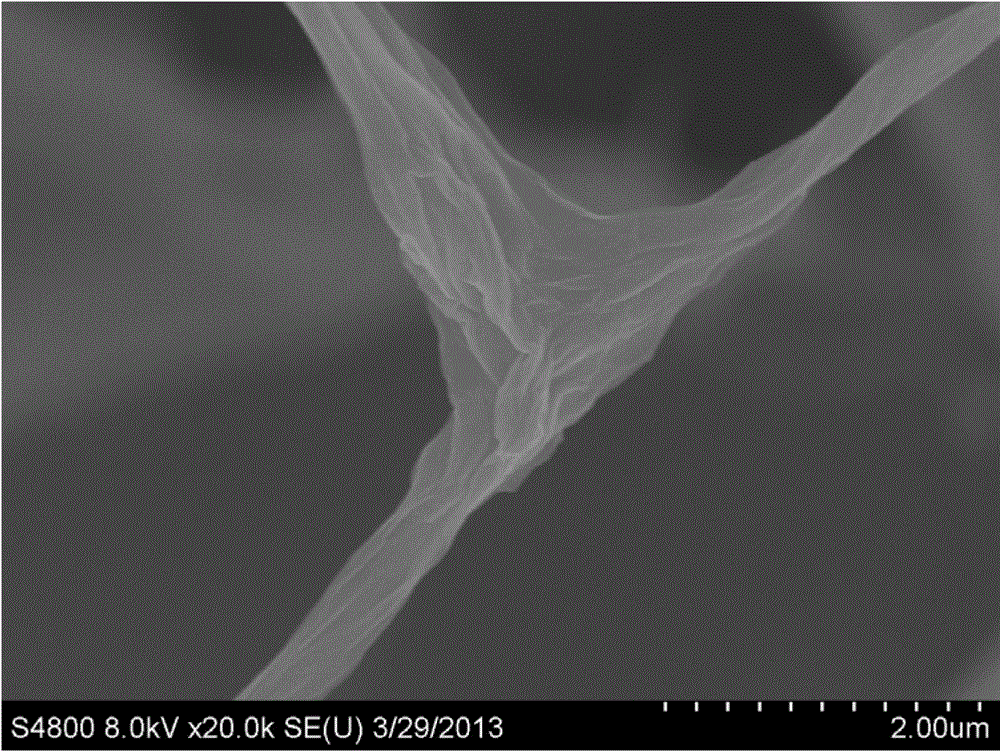

[0024] The embodiment of the present invention discloses a preparation method of graphene oxide fiber, comprising:

[0025] The graphene oxide aqueous solution is freeze-solidified in liquid nitrogen, and then freeze-dried to obtain graphene oxide fibers; the graphene oxide is prepared according to a chemical oxidation method.

[0026] In the process of preparing the graphene oxide fiber skeleton, the present invention first freezes and solidifies the graphene oxide aqueous solution in liquid nitrogen. Graphene oxide is the product of flake graphite after chemical oxidation and exfoliation. There are three methods for preparing graphene oxide: Brodie method, Staudenmaier method and Hummers method. Since the graphene oxide prepared by the Hummers method has a higher degree of oxidation and contains more oxygen-containing functional groups, the graphene oxide aqueous solution of the present invention is preferably prepared according to the Hummers method, which is a method well...

Embodiment 1

[0039] (1) Add 1g of natural graphite and 1.2g of potassium nitrate to 46ml of concentrated sulfuric acid with a concentration of 98wt%, stir for 10 minutes, then add 6g of potassium permanganate, raise the temperature to 40°C, heat and stir for 6h, then add 80ml of deionized water, and raise the temperature to 80°C, heat and stir for 0.5h, then add 200ml of deionized water and 6ml of hydrogen peroxide, the reactant turns golden yellow, and the reaction stops. Finally, under the condition of high-speed centrifugation, it was repeatedly washed with deionized water until the pH of the supernatant was neutral, and the graphene oxide concentrate was obtained.

[0040] (2) Prepare the graphene oxide concentrate in step (1) into an aqueous solution with a concentration of 2 mg / ml, and then take 60 ml of it and pour it into a mold with a length of 20 cm, a width of 10 cm, and a thickness of 3 mm.

[0041] (3) Rapidly immerse the mold in liquid nitrogen to rapidly freeze and solidify ...

Embodiment 2

[0046] (1) A 1.25 mg / ml graphene oxide aqueous solution was prepared by the Hummers method.

[0047] (2) Pour 60ml of the graphene oxide aqueous solution obtained in step (1) into a mold with a length of 20cm, a width of 10cm, and a thickness of 3mm.

[0048] (3) Rapidly immerse the mold in liquid nitrogen to rapidly freeze and solidify the graphene oxide solution in the mold.

[0049] (4) Freeze-dry the graphene oxide aqueous solution solidified in step (3) with a freeze dryer to obtain 75 mg of a complete three-dimensional network graphene oxide fiber skeleton.

[0050] (5) Perform thermal reduction treatment at 50°C for 0.5-5 hours on the skeleton obtained in step (4) to obtain a graphene three-dimensional network skeleton.

[0051] (6) Mix JL-236 high-strength epoxy resin and JH-239 epoxy curing agent evenly in a mass ratio of 10:3, and then mix it with the graphene three-dimensional network skeleton obtained in step (5) in a mass ratio of 500 : 1 curing compound. Curin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com