Copolymerization-immobilized beta-cyclodextrin porous separation material as well as preparation method and application thereof

A separation material, cyclodextrin technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the problem of particle surface reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

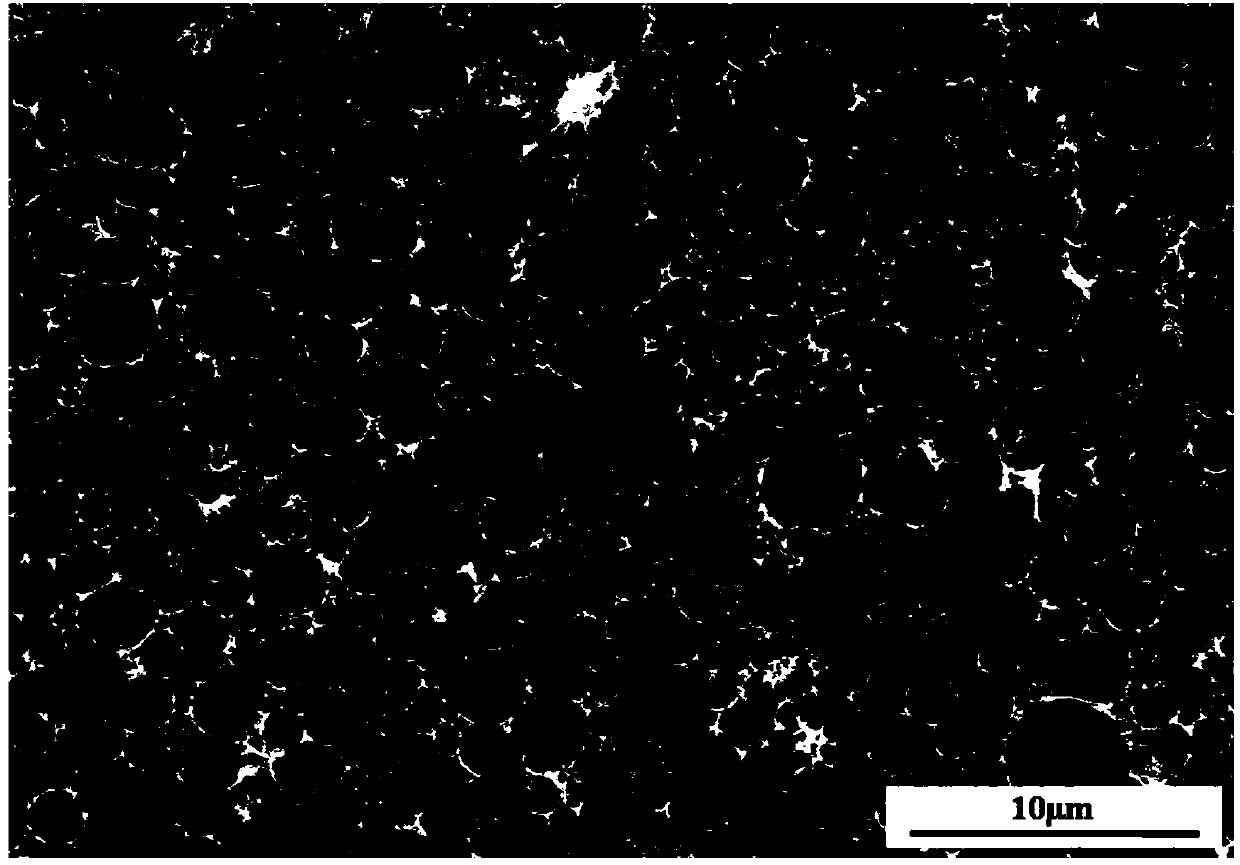

Image

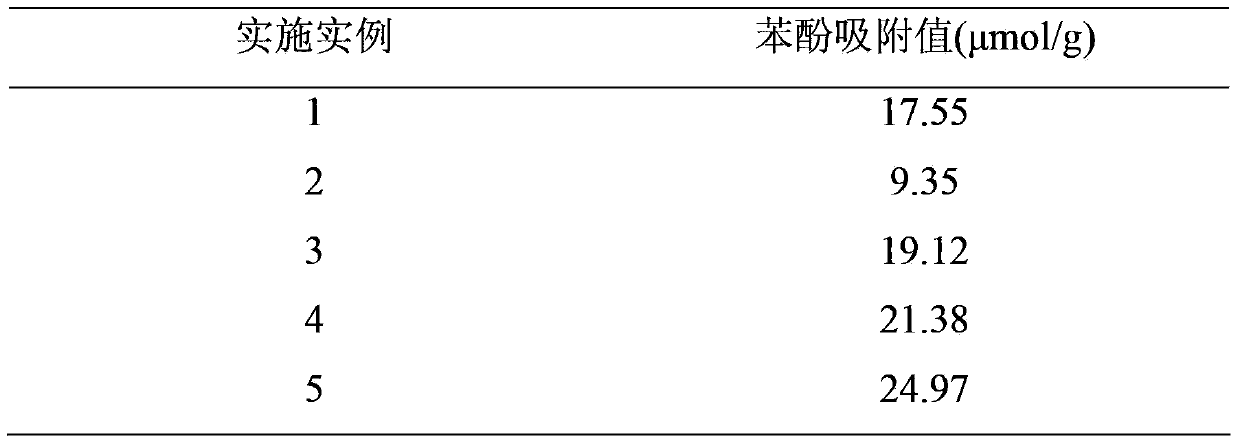

Examples

Embodiment 1

[0022] Firstly, 2.27g β-CD was added into 50mL / 50mL anhydrous DMF / anhydrous DMSO mixed solution to fully dissolve β-CD, then 8.96g NaOH was added and stirred vigorously for 1h to mix well. Slowly add 14.4 mL of LC in an ice-water bath at 5°C while stirring 3 h 5 Br, reacted under vigorous stirring for 48 hours, filtered to remove the solid precipitate after the reaction stopped, added 8 to 10 times of water to the filtrate to precipitate the product, extracted with ethyl acetate and then rotary evaporated to obtain vinyl β-CD.

[0023] At room temperature, mix 1g of vinyl β-CD and 2g of styrene evenly, add 0.75g of p-vinylbenzene and 1.01g of Span 80 to form a continuous phase; mix 0.188g of K 2 SO 4 and 0.075gK 2 S 2 o 8 Dissolve in 45g of deionized water to form a dispersed phase. Slowly drop the dispersed phase into the continuous phase under high-speed stirring, and stir evenly after the dropwise addition to form a reverse-phase thick emulsion. Then, the concentrate...

Embodiment 2

[0025] Firstly, add 2.27g β-CD into 40mL / 60mL anhydrous DMF / anhydrous DMSO mixed solution to fully dissolve β-CD, then add 5.04g NaOH and stir vigorously for 1h to mix well. Slowly add 11.4 mL of LC in a water bath at 20°C while stirring 3 h 5 Br, reacted under vigorous stirring for 72 hours, filtered to remove the solid precipitate after the reaction stopped, added 8 to 10 times of water to the filtrate to precipitate the product, extracted with ethyl acetate and rotary evaporated to obtain vinyl β-CD.

[0026] At room temperature, stir and mix 0.6g vinyl β-CD and 2.4g styrene evenly, add 0.375g p-vinylbenzene and 0.505g Span 80 to configure the continuous phase; mix 0.188g K 2 SO 4 and 0.075gK 2 S 2 o 8 Dissolve in 47g of deionized water to form a dispersed phase. Slowly drop the dispersed phase into the continuous phase under high-speed stirring, and stir evenly after the dropwise addition to form a reverse-phase thick emulsion. Then, the concentrated emulsion was pl...

Embodiment 3

[0028] First, add 2.27g β-CD into 40mL / 60mL anhydrous DMF / anhydrous DMSO mixed solution to fully dissolve β-CD, then add 4.04g NaOH and stir vigorously for 1h to mix well. Slowly add 11.4 mL of LC in a water bath at 20°C while stirring 3 h 5 Br, reacted under vigorous stirring for 72 hours, filtered to remove the solid precipitate after the reaction stopped, added 8 to 10 times of water to the filtrate to precipitate the product, extracted with ethyl acetate and rotary evaporated to obtain vinyl β-CD.

[0029] At room temperature, stir and mix 1g vinyl β-CD and 2g styrene evenly, add 0.375g p-vinylbenzene, 1.405g Span 20 to configure the continuous phase; mix 0.188g K 2 SO 4 and 0.075gK 2 S 2 o 8 Dissolve in 45g of deionized water to form a dispersed phase. Slowly drop the dispersed phase into the continuous phase under high-speed stirring, and stir evenly after the dropwise addition to form a reverse-phase thick emulsion. Then, the concentrated emulsion was placed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com