A parallel three-truss full load passenger car body structure

A bus body structure, truss-type technology, applied in load-bearing body structure, bus superstructure, superstructure, etc., can solve the problem of the poor ability of small cross-section rods to bear bending loads and reduce the bending load bearing capacity of grille underframes capacity, reducing the load-carrying utilization rate of skeleton structure materials, etc., to achieve the effect of reducing the cost of the whole vehicle and subsequent maintenance costs, improving control stability, and improving distribution stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention is further described in conjunction with accompanying drawing:

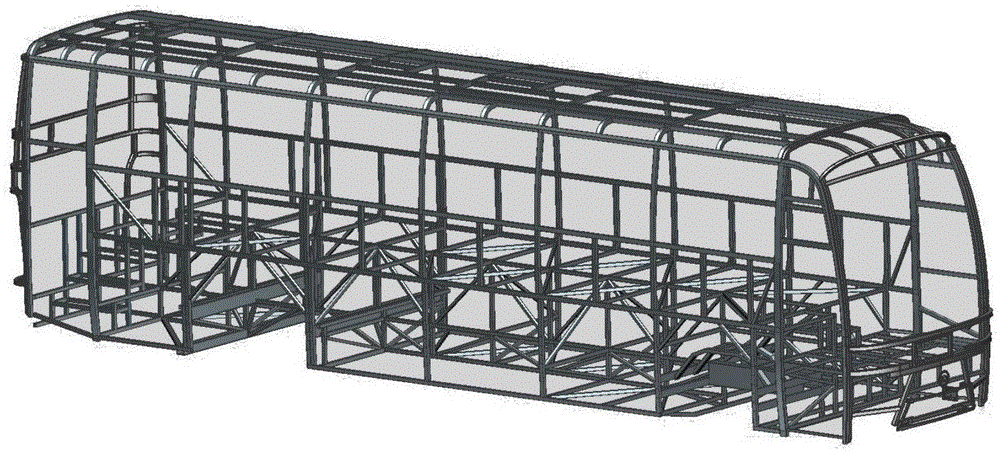

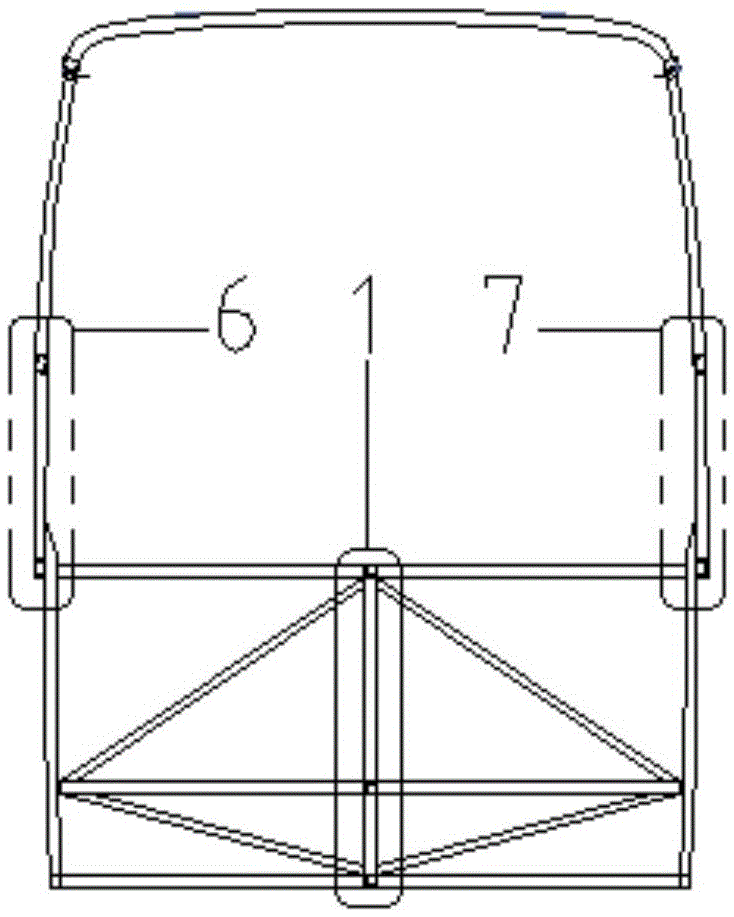

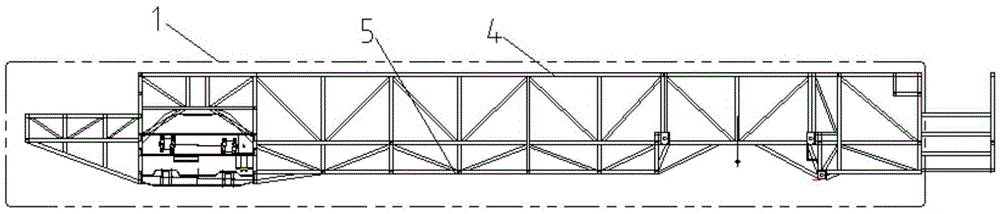

[0031] This scheme proposes a parallel three-truss full-load passenger car body structure, and the entire vehicle structure is made of tailor-welded small-section rods. Vehicle skeleton such as figure 1 As shown, the three-truss structure concept is as figure 2 , image 3 , Figure 4 and Figure 5 Structure shown. The middle truss parallel to the xoz coordinate plane of the vehicle body coordinate system is a truss structure with diagonal bracing that runs through the front and rear of the vehicle body. Together with the left truss 6 and the right truss 7, it forms a three-truss-type integral anti-bending load-bearing structure, which makes the whole vehicle have extremely strong anti-bending Carrying capacity.

[0032] This plan proposes a parallel three-truss full-load passenger car body structure. The three parallel trusses are connected through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com