Device and method for brazing brass waveguide and water-cooled plate with high bonding rate in vacuum state

A vacuum state, wave guide technology, applied in electric heating devices, welding equipment, metal processing and other directions, can solve the problem of low bonding rate, and achieve the effects of no welding deformation, reliable results, and simple deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

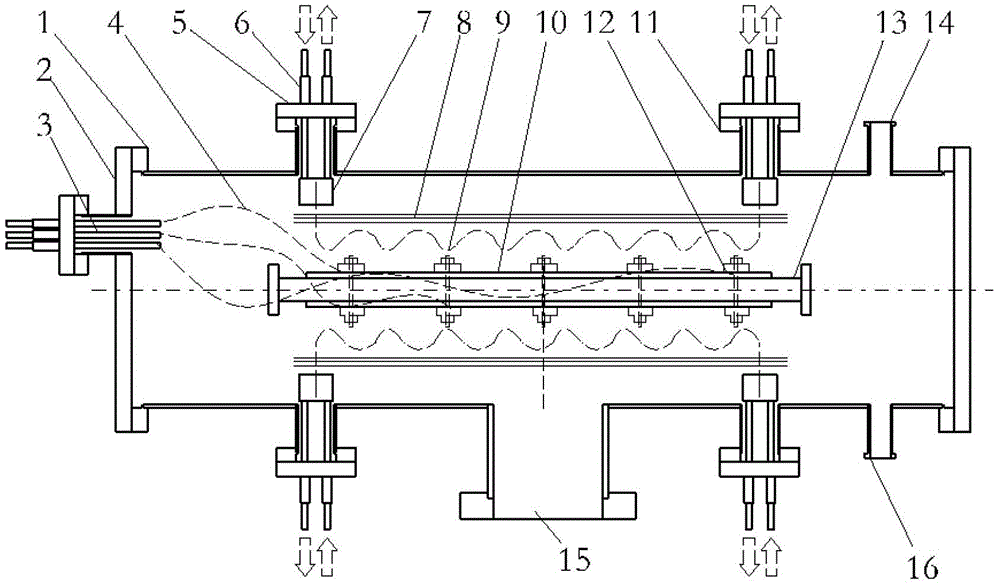

[0031] like figure 1 shown. A device for brazing a brass waveguide and a water-cooled plate with a high bonding rate in a vacuum state. Brazing solder is arranged on the brazed tube wall area of the brass waveguide 13 to be brazed, and the water-cooled plate 10 is fixed on the brass waveguide 13 to be brazed. The area of the waveguide 13 to be brazed constitutes the workpiece, the brazing solder is held together by the water-cooled plate 10 and the brass waveguide 13, a vacuum container 1 is set, and the workpiece is placed in the vacuum container 1 as a whole;

[0032] The vacuum container 1 is provided with a plurality of sections of heating elements 9 surrounding the workpiece. The heating elements 9 are close to but not in contact with the workpiece. A multi-layer shielding assembly 8 is respectively arranged between each section of the heating element 9 and the inner wall of the vacuum container 1 at the corresponding position. The vacuum container Corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com