Full-automatic feeding device of punching machine

A feeding device and fully automatic technology, applied in the field of stamping machines, can solve the problems of automatic feeding equipment and stamping equipment shutdown, refueling adjustment time exceeding production time, and long adjustment time of refueling device, so as to avoid industrial accidents and compact equipment , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

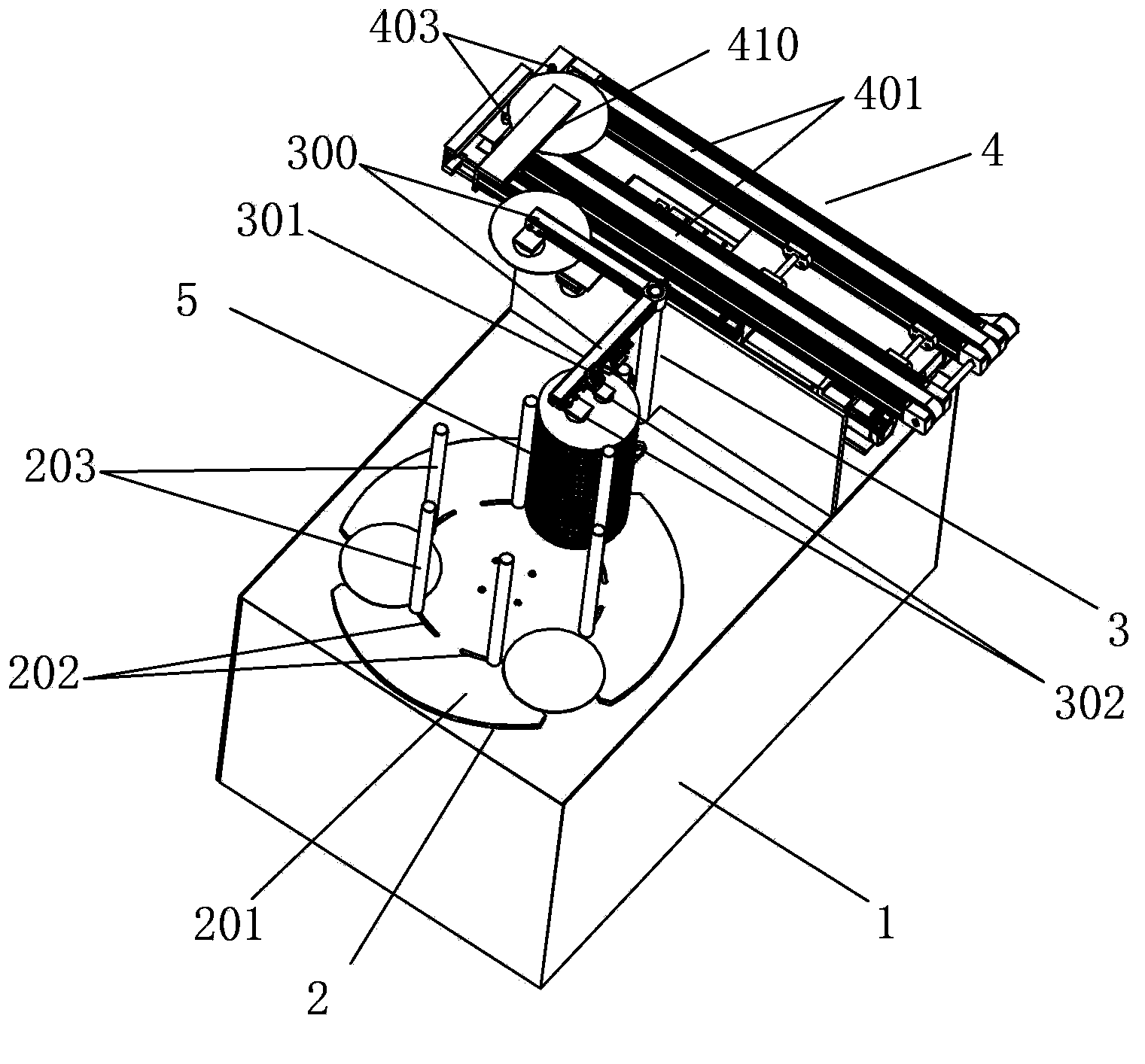

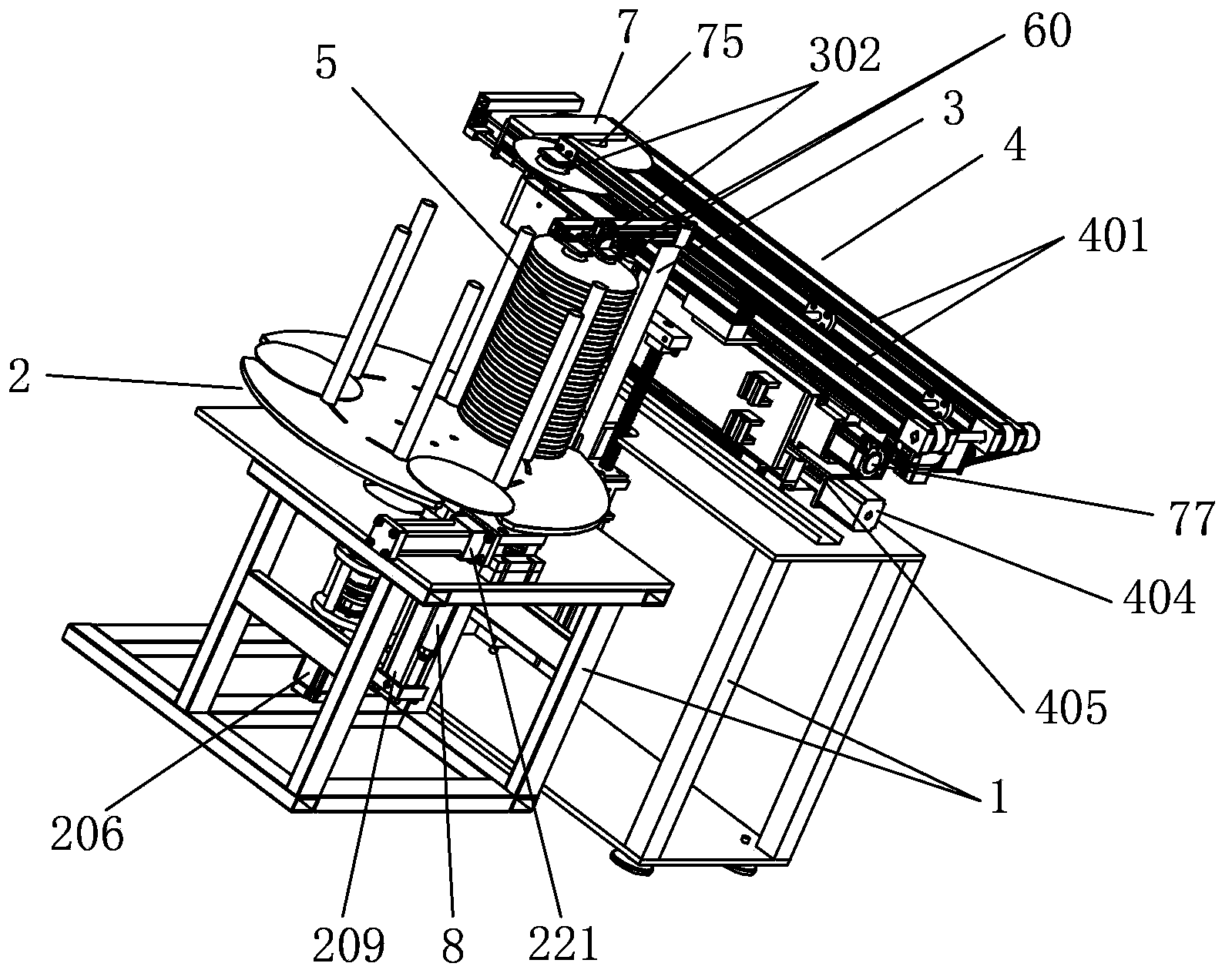

[0030] The present invention will be further described below with specific embodiments in conjunction with the drawings, see figure 1 — Figure 8 :

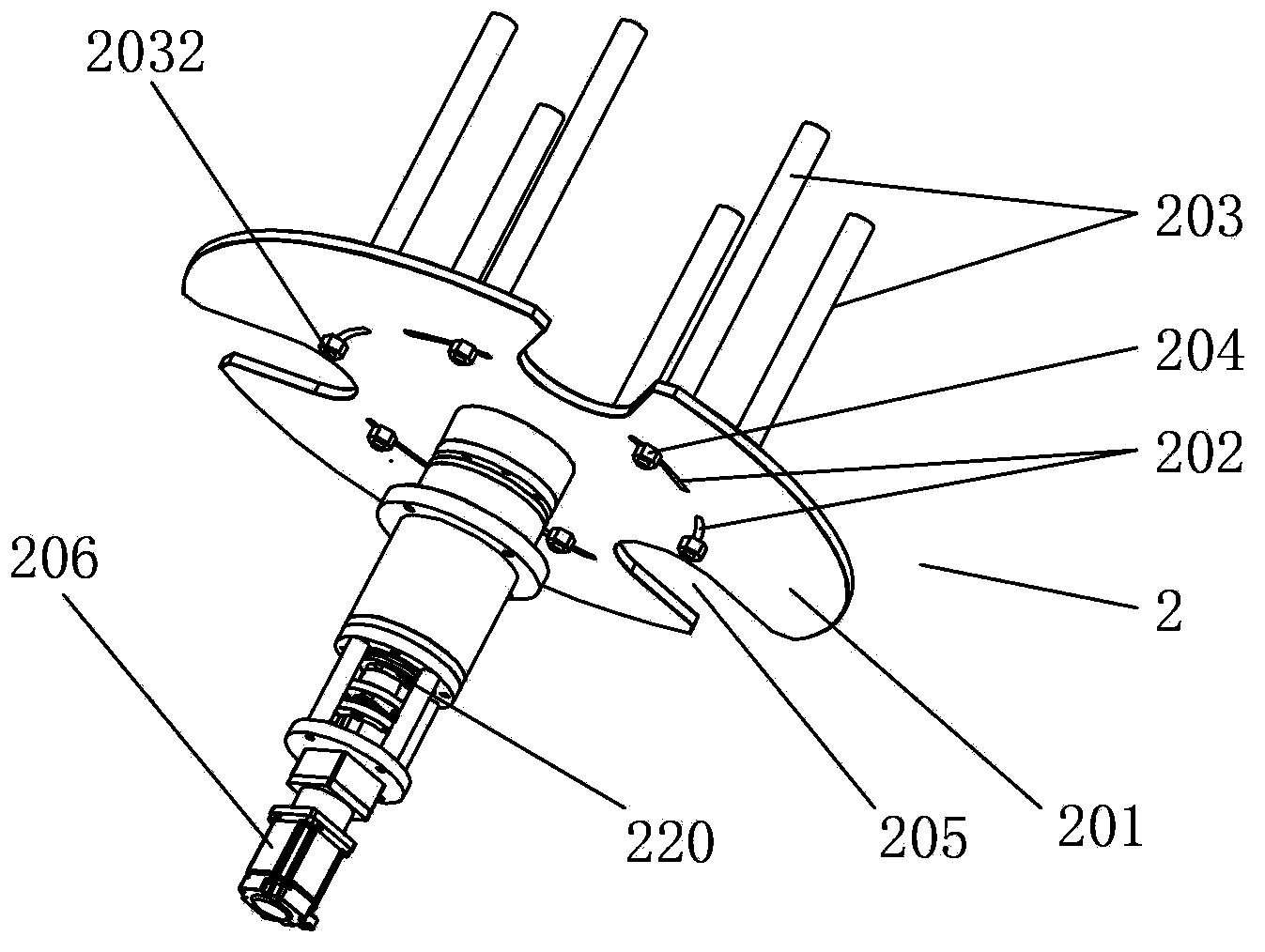

[0031] The full-automatic feeding device of the punching machine includes a feeding table and a feeding mechanism whose actions are controlled by a controller. The specific structure of the feeding table 2 is: a rotating shaft 220 driven by a power device installed on the frame 1 is fixed Turntable 201, the same radius circle drawn by the same center on the turntable 201 is evenly distributed with more than two sets of positioning grooves, each set of positioning grooves consists of two spaced arc grooves 202, and each arc groove 202 is provided There is a positioning rod 203. The lower side of the turntable 201 is provided with a positioning rod positioning device. A material level is formed between the two positioning rods 203 on each group of arc grooves 202, and each material level is provided with an ejector rod for passing thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com