A watch case blank production process

A production process and blank processing technology, applied in the field of watch case blank production process, can solve the problems of unable to deal with plates, large remaining corners, expensive prices, etc., achieve good economic benefits, reduce the generation of corner waste, and improve material utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

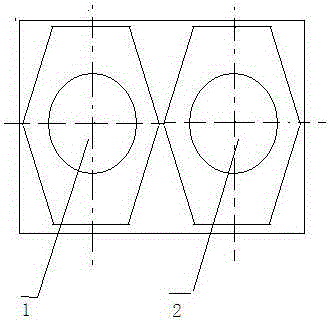

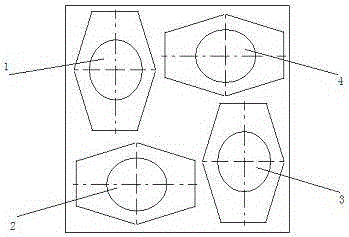

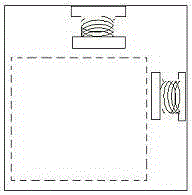

Image

Examples

Embodiment Construction

[0015] the following to 0 Cr 18 Ni 9 A series of stainless steel production of medium-sized series of watch case blanks is taken as an example to provide a specific embodiment of the present invention, which is used to further illustrate the present invention.

[0016] The production process equipment of the present invention includes J31-80 press, J21-80 press, J31-160 closed single-point press, blanking die, punching die, drop shape die, presser die, medium temperature box-type resistance furnace , 0‐125 vernier caliper.

[0017] The processing material of production technique of the present invention comprises 0 Cr 18 Ni 9 Series stainless steel, usually has two specifications, specification 1 is 75*1000mm stainless steel plate, specification 2 is 79*1000mm stainless steel plate.

[0018] The production process of the present invention includes the following processes, a blanking process, a punching process, a shape drop process and a presser foot process.

[0019] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com