aqua regia reactor

A technology of reaction kettle and aqua regia, which is applied in the field of metal recovery equipment, can solve the problems of restricting product promotion, low degree of automation, and great harm to human body, and achieve the effect of simple structure design, high degree of automation, and improved stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The best embodiment of the present invention will be further described in detail below.

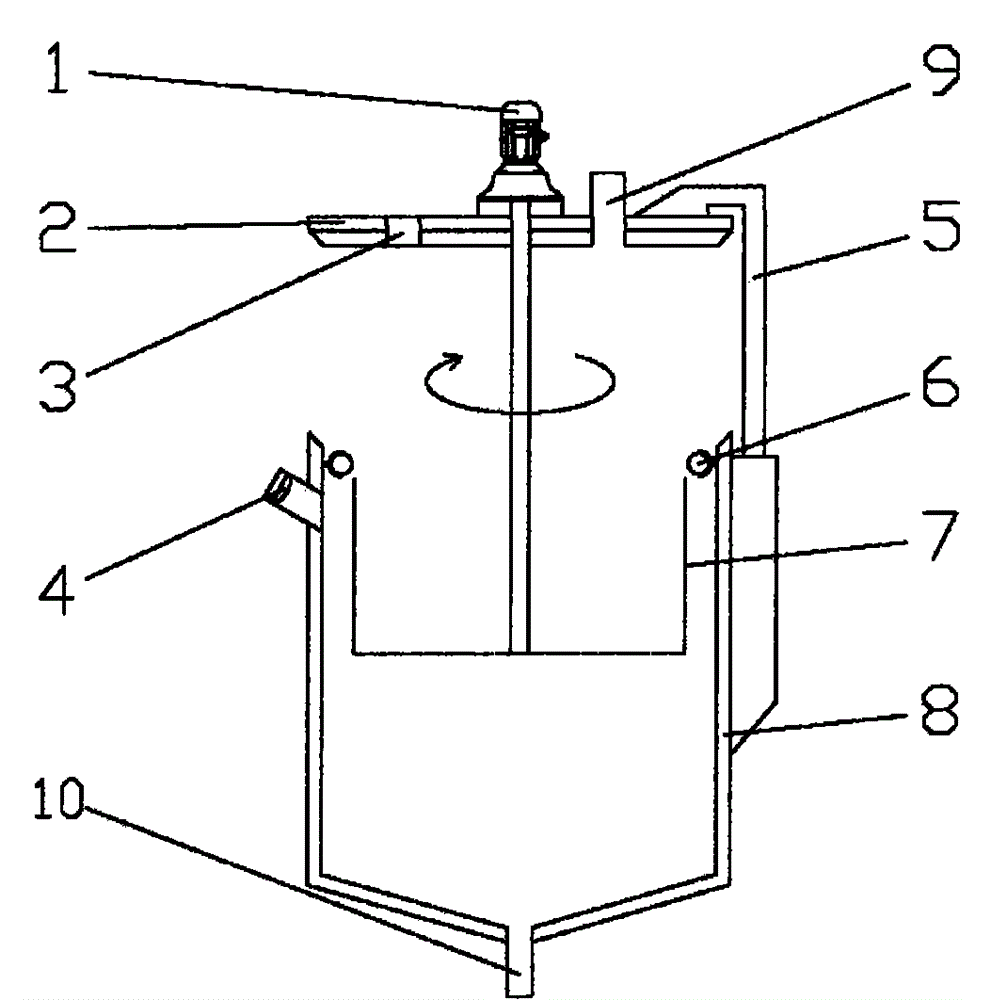

[0020] Such as figure 1 and 2 As shown, the aqua regia reactor includes a stirring motor 1, a liftable kettle cover 2, an automatic lifting mechanism 5, a rotating titanium basket 7, and a kettle body 8, and the kettle body 8 and the liftable kettle cover 2 are resistant The titanium material of aqua regia can lift the kettle cover 2 and the sealing cover is buckled on the top of the kettle body 8. The outer wall of the kettle body 8 is provided with an automatic lifting mechanism 5. The automatic lifting mechanism 5 is composed of a cylinder, a piston and a lifting rod. The cylinder passes through the The air pipe is connected to the compressed air system. When the compressed air is input into the cylinder, the piston drives the lifting rod to rise, and vice versa, it is connected to the liftable kettle cover 2, which can control the liftable kettle cover 2 to automatically rise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com