Dual-fan welding smoke absorption and purification method

A technology with double blowers and welding fume, which is applied to chemical instruments and methods, separation methods, cleaning methods and appliances, etc., can solve the problems of small resistance, large suction lift, low absorption and purification efficiency, etc., and achieve high efficiency and low equipment resistance , Improve the effect of absorption and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

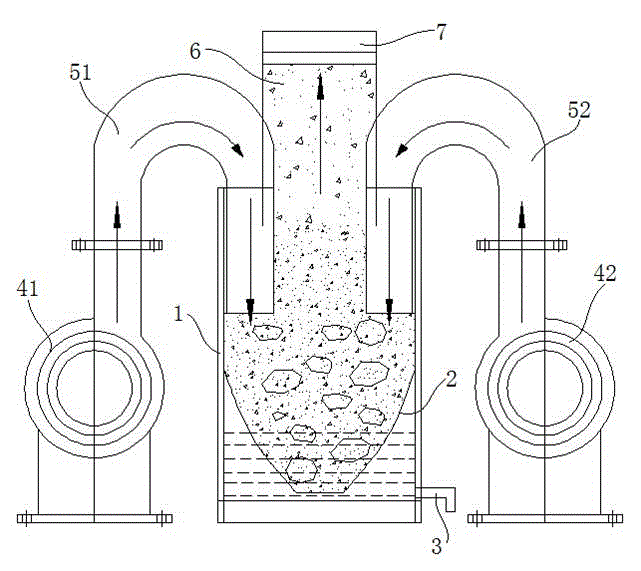

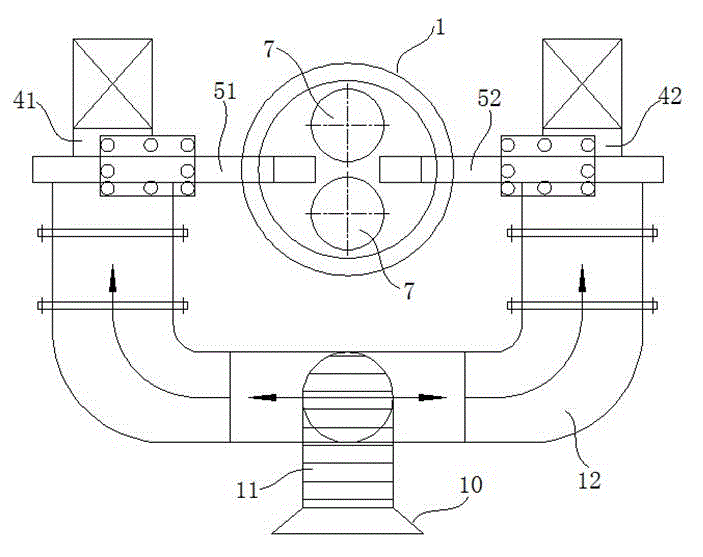

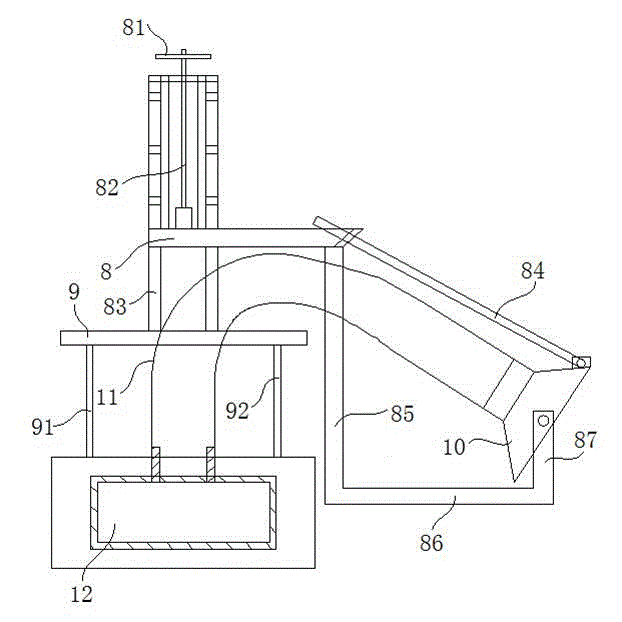

[0034] combine figure 1 , figure 2 and image 3 , a dual-fan welding fume absorption purifier in this embodiment includes a smoking mechanism, a welding fume purification mechanism, and a welding fume tracking mechanism. The lower part of the housing of the entire dual-fan welding fume absorption purifier is equipped with four universal wheels for easy movement , The use and maintenance cost is extremely low. The smoking mechanism in this embodiment is used to absorb welding fumes and transport them to the welding fume purification mechanism. The first fan outlet duct 51 and the second fan outlet duct 52 (such as figure 2 shown), the smoking hood 10 communicates with the fan inlet pipe 12 through the smoking hose 11, the fan inlet pipe 12 is in a "U" shape structure, and the fan suction port of the first fan 41 is connected to the fan inlet One end of the air duct 12 is connected, the fan suction port of the second fan 42 is connected with the other end of the fan inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com