Breast sucking cover structure of breast pump

A breast pump and breast pump technology, which is applied to breast pumps, suction devices, etc., can solve the problems of physical aging of the structure of the breast pump, affecting the sealing performance of the breast pump, deformation of breast pads and cups, etc., and achieves air tightness. Good, not easy to deform, avoid physical aging and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

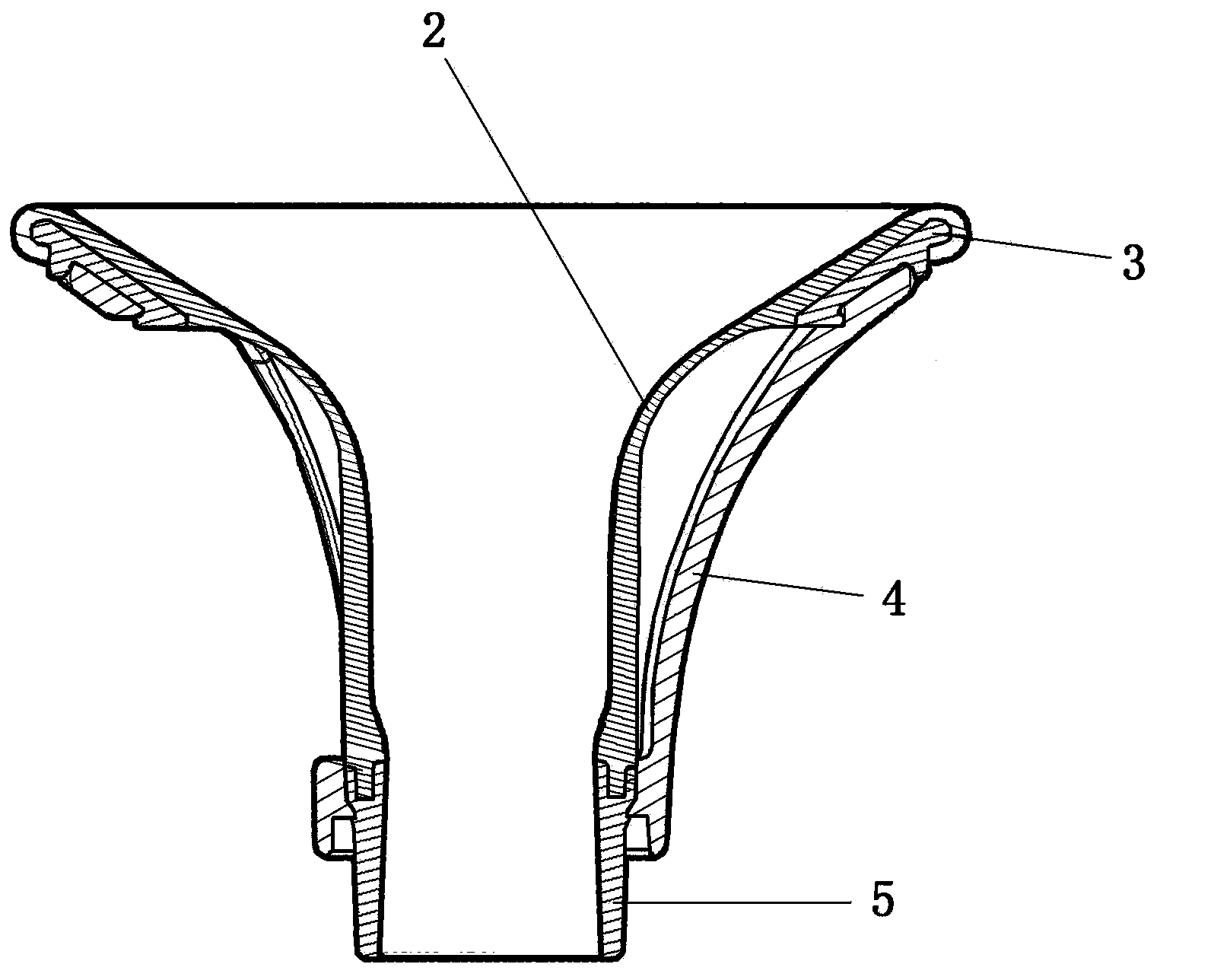

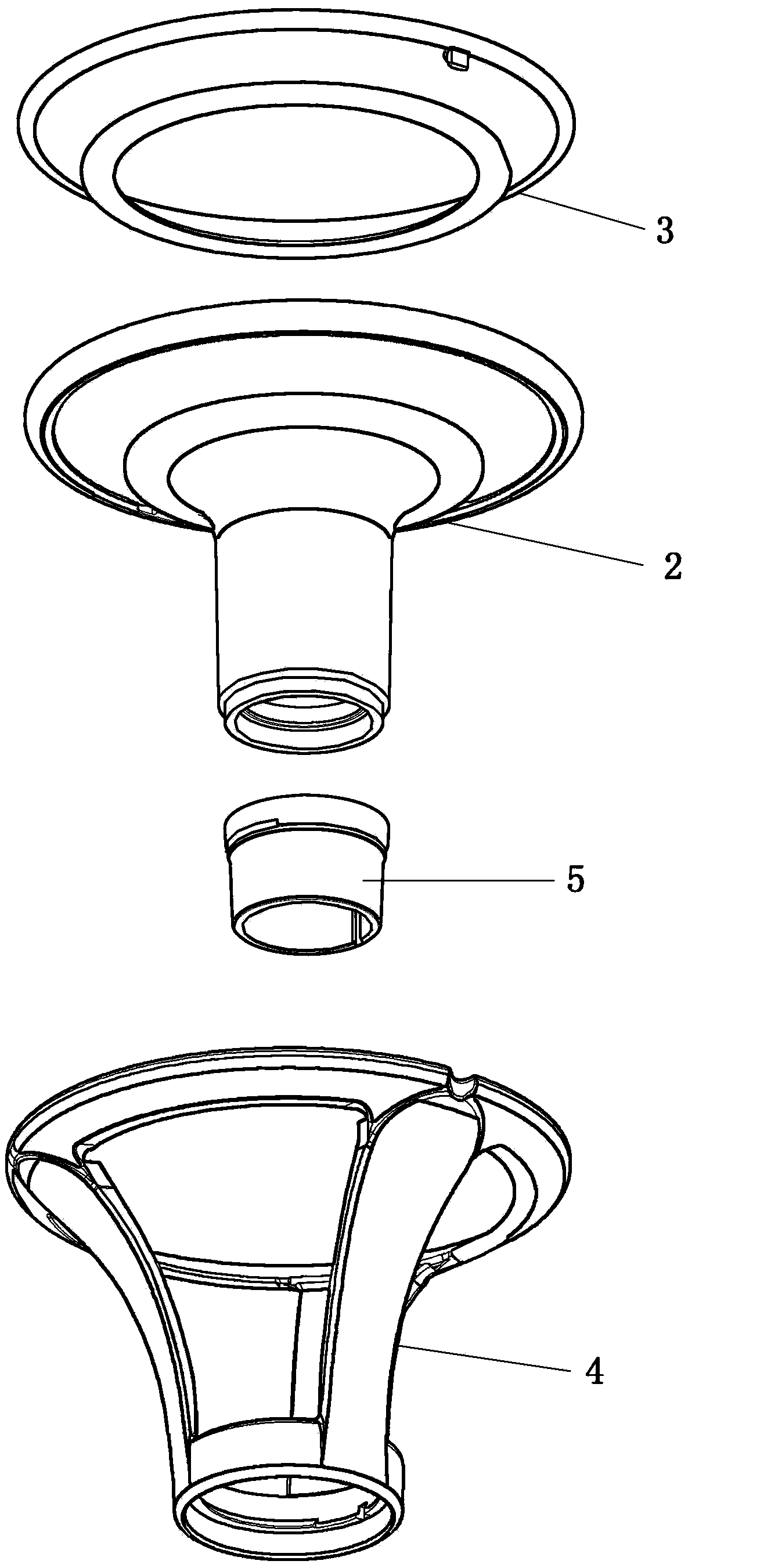

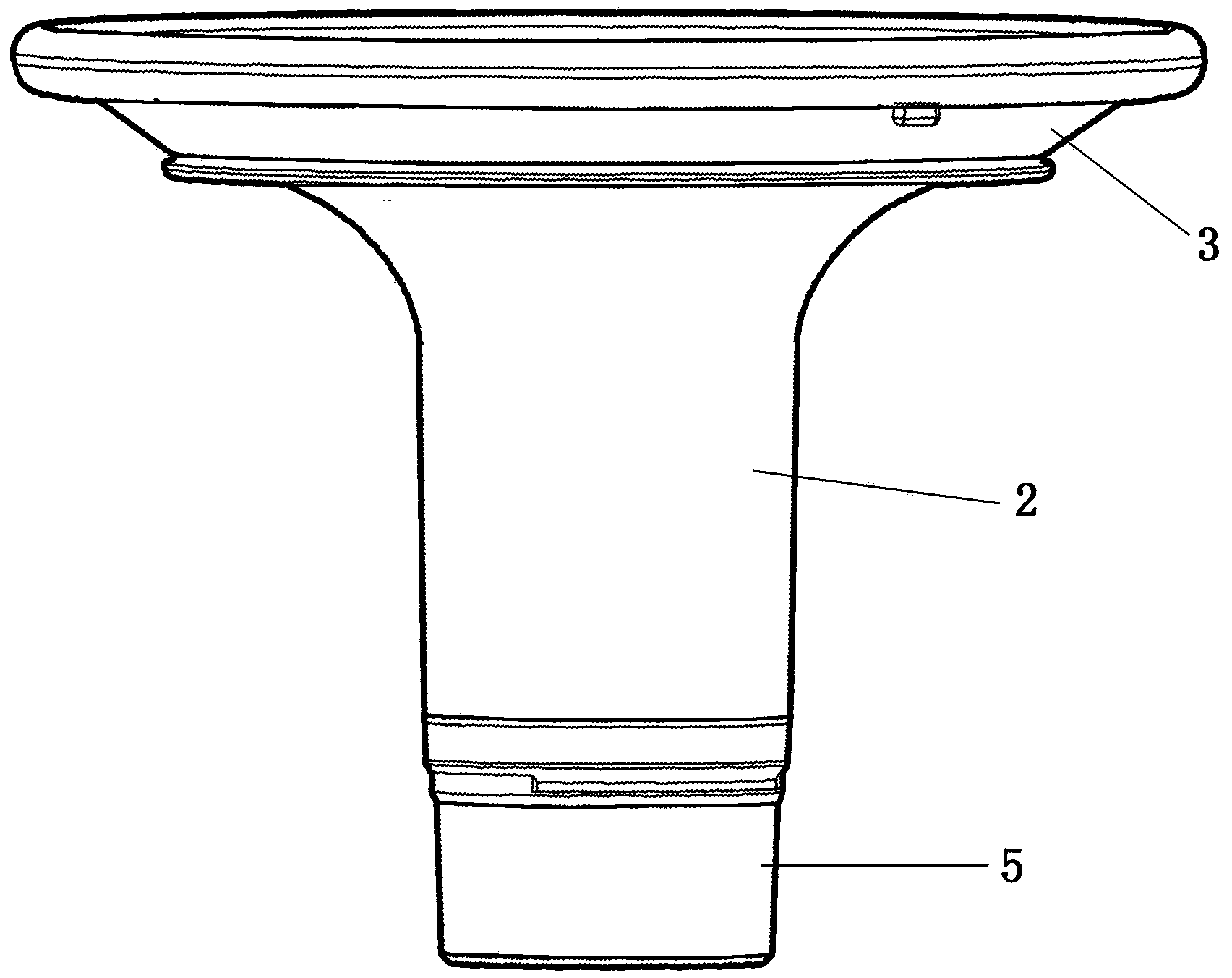

[0021] Referring to the accompanying drawings, a breast shield structure of a breast pump according to the present invention, the breast shield structure includes a breast pump inner cover assembly and a supporting outer frame body 4; the breast pump inner cover assembly includes: a large port Seal the inner ring piece 3, the breast shield body 2, and the cup interface 5.

[0022] The connection between the large port of the breast shield body 2 and the large port sealing inner ring piece 3 is a secondary injection molding structure;

[0023] The connection between the small port of the breast shield body 2 and the cup interface 5 is a secondary injection molding structure.

[0024] The material of the large port sealing inner ring piece 3 and the cup interface 5 is PPSU, and its composition is polyphenylene sulfone. In specific implementation, RADEL R can be used.

[0025] The material of the breast shield body 2 is SIL liquid silicone.

[0026] More than two skeletons are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com