Electro-hydraulic servo follow-up system for long-span transmission line conductor and ground wire release

An electro-hydraulic technology for power transmission lines and pay-off lines, which is applied to overhead lines/cable equipment, etc., can solve the problems of not having the ability to track targets, easily causing accidents, and high construction costs, and achieving easy construction and transportation, high operation efficiency, and improved The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

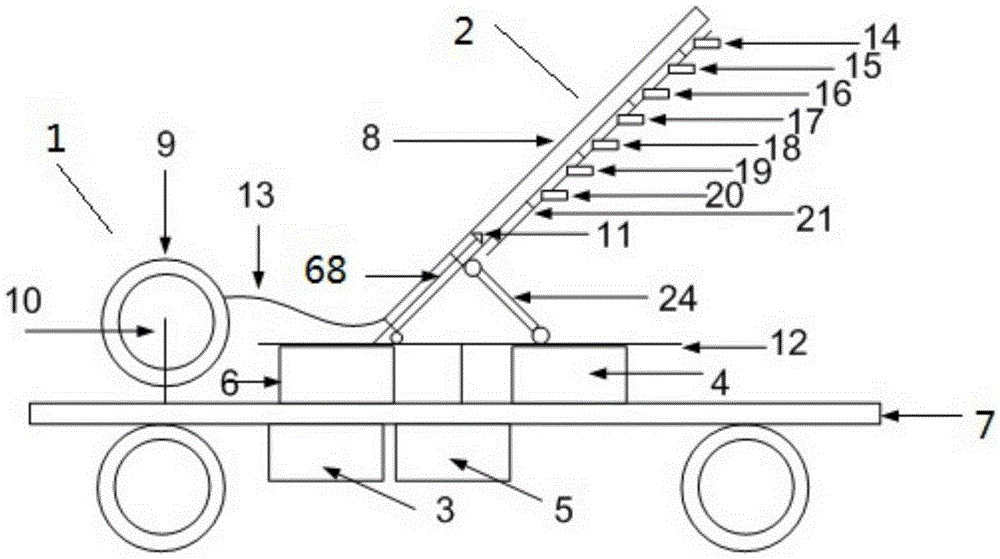

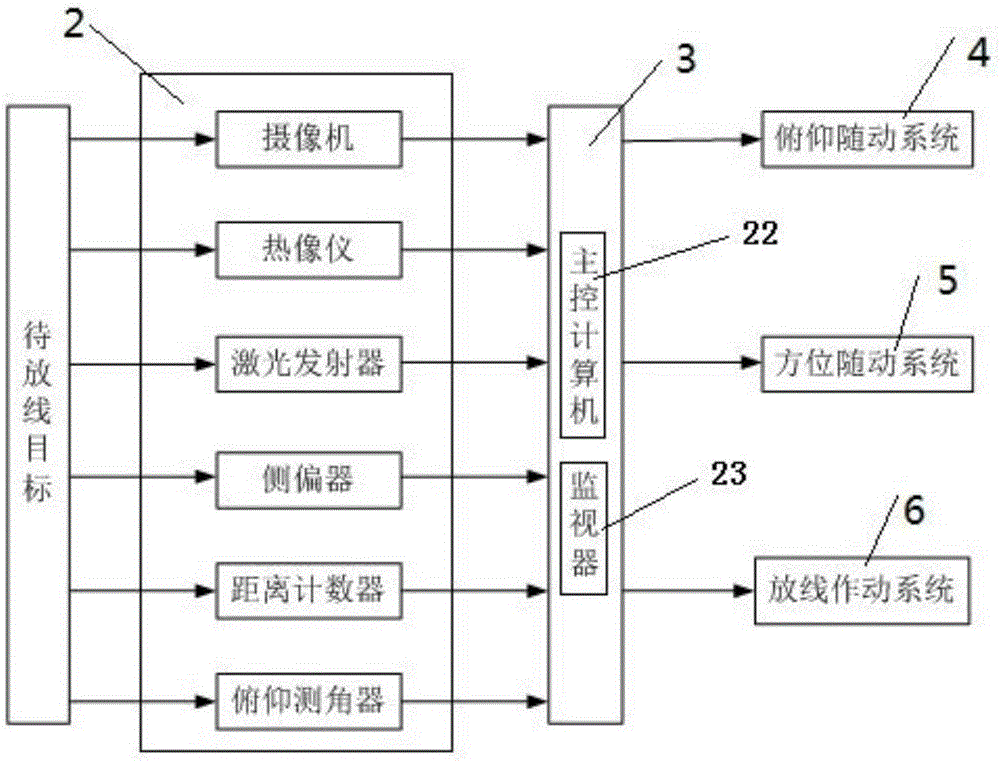

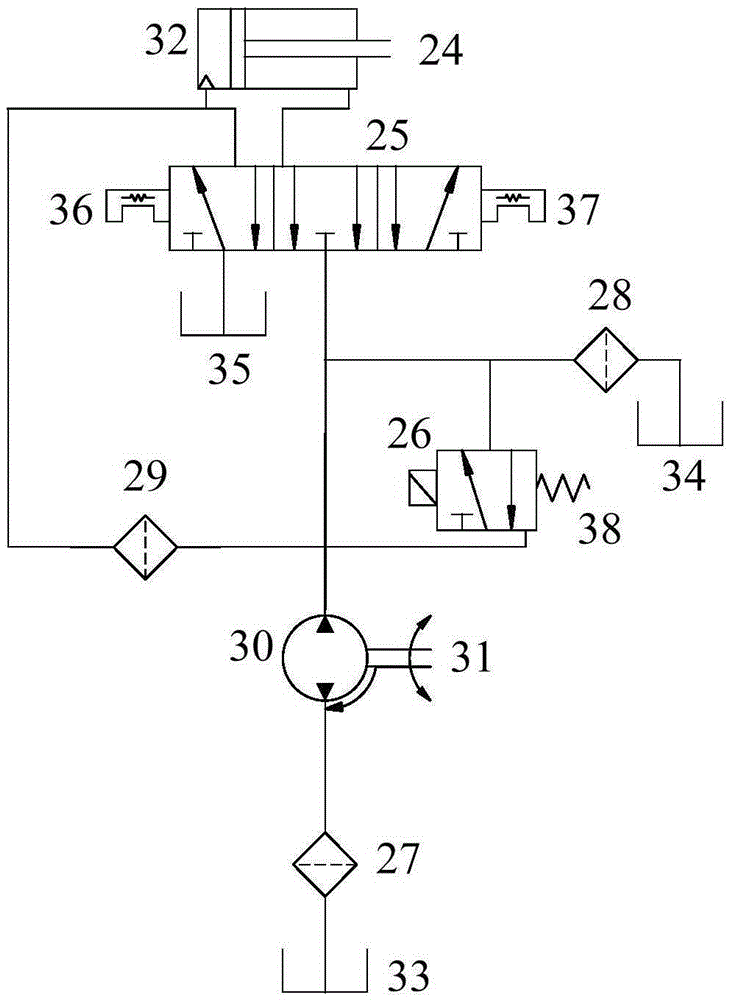

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific examples.

[0022] refer to figure 1—7. An electro-hydraulic servo follow-up system for large-span transmission line conductor and ground wire release, which includes a measurement and tracking system 2, a main control system 3, a pitch follow-up control system 4, and an azimuth follow-up on the vehicle-mounted mechanical system 1. The control system 5 and the electro-hydraulic pay-off actuation system 6, the measurement and tracking system 2, the pitch follow-up control system 4, the azimuth follow-up control system 5 and the electro-hydraulic pay-off actuation system 6 are all electrically connected to the main control system 3 . The vehicle-mounted mechanical system 1 is used to carry the measurement and tracking system 2, the main control system 3, the pitch follow-up control system 4, the azimuth follow-up control system 5 and the electro-hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com