Annular seal assembling jig

A technology of annular sealing and assembling fixtures, which is applied in the direction of manufacturing tools, hand-held tools, workpiece clamping devices, etc., can solve the problems of annular sealing rupture and difficulty in assembling spherical bodies, and achieve the effect of preventing rupture and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

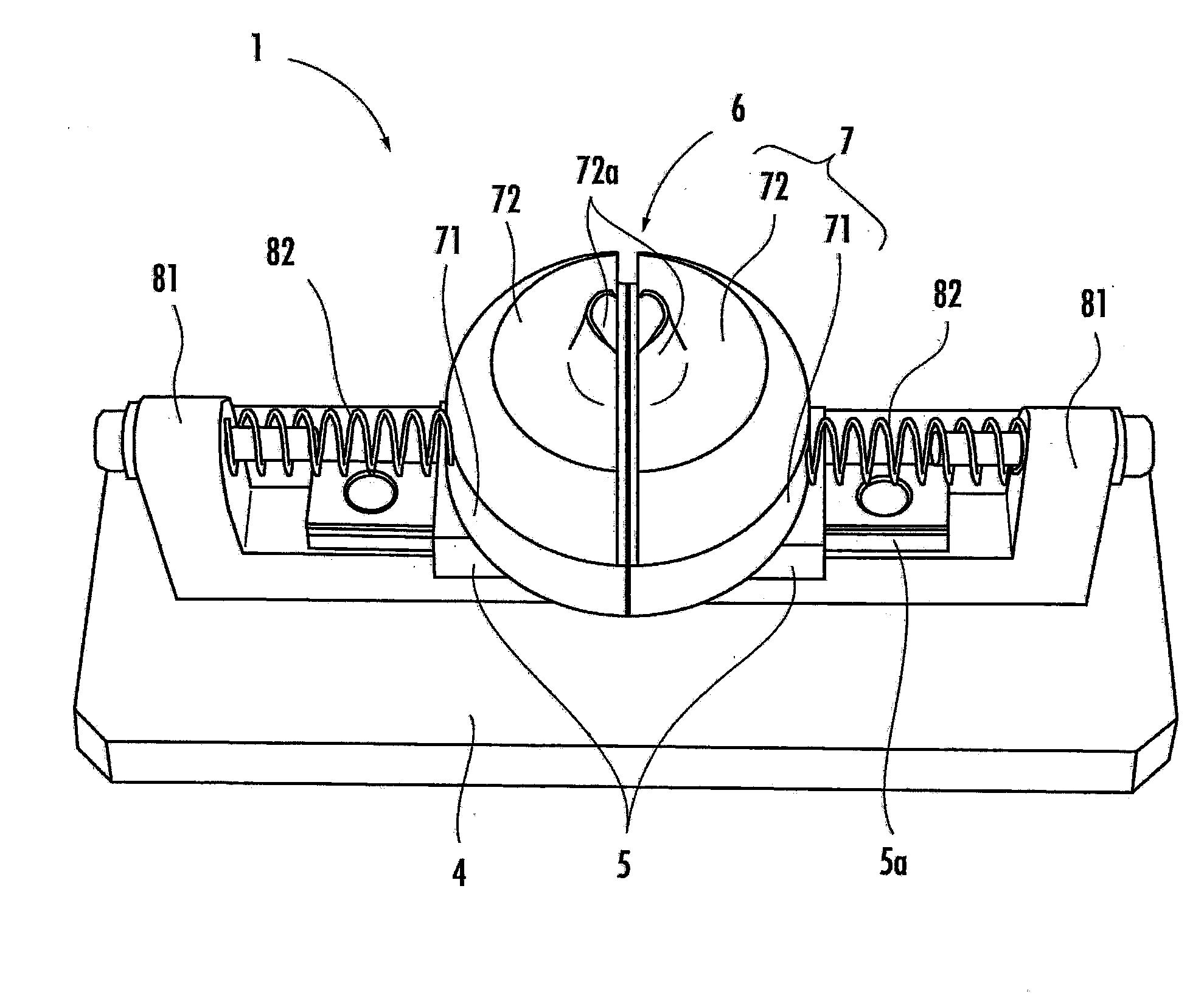

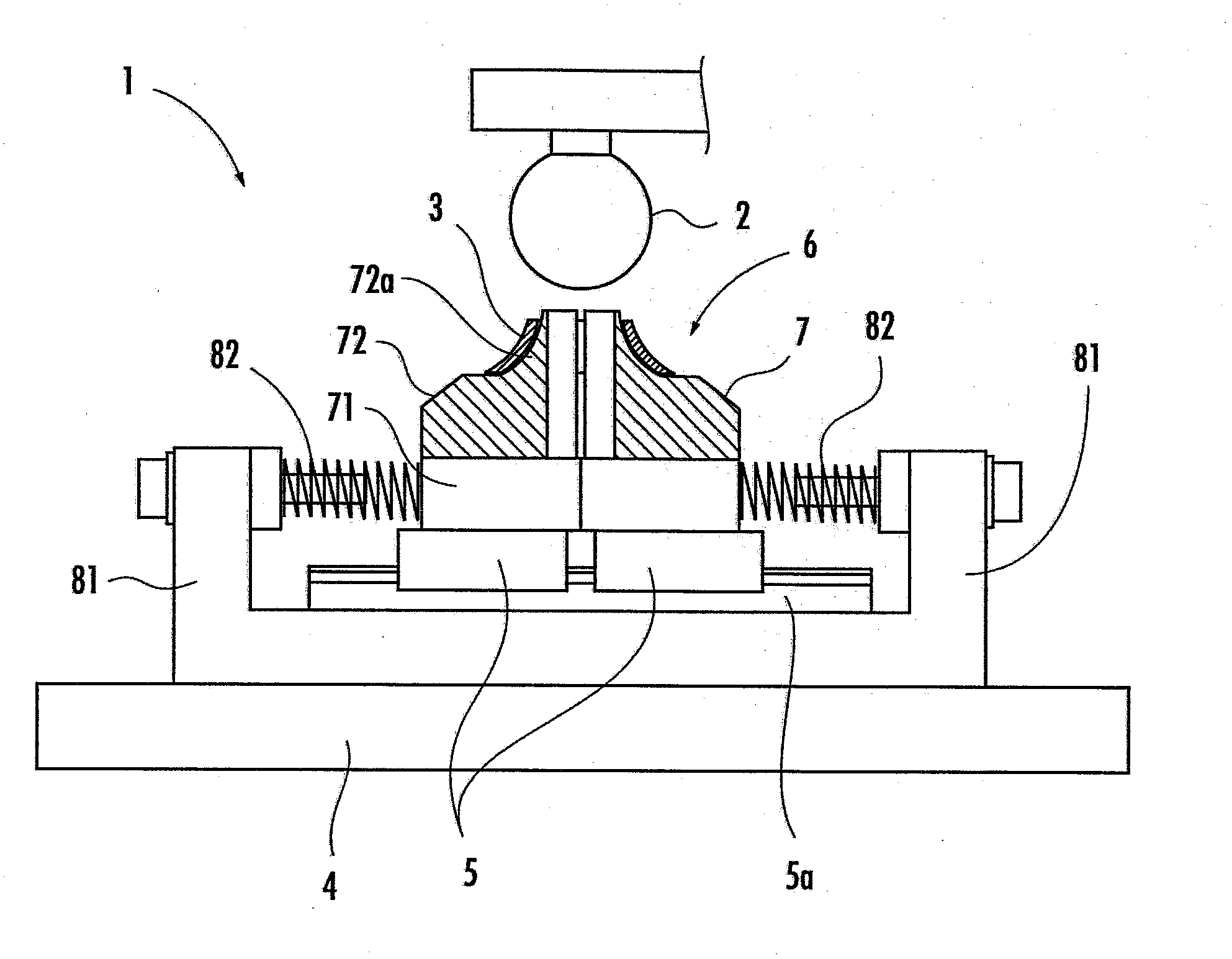

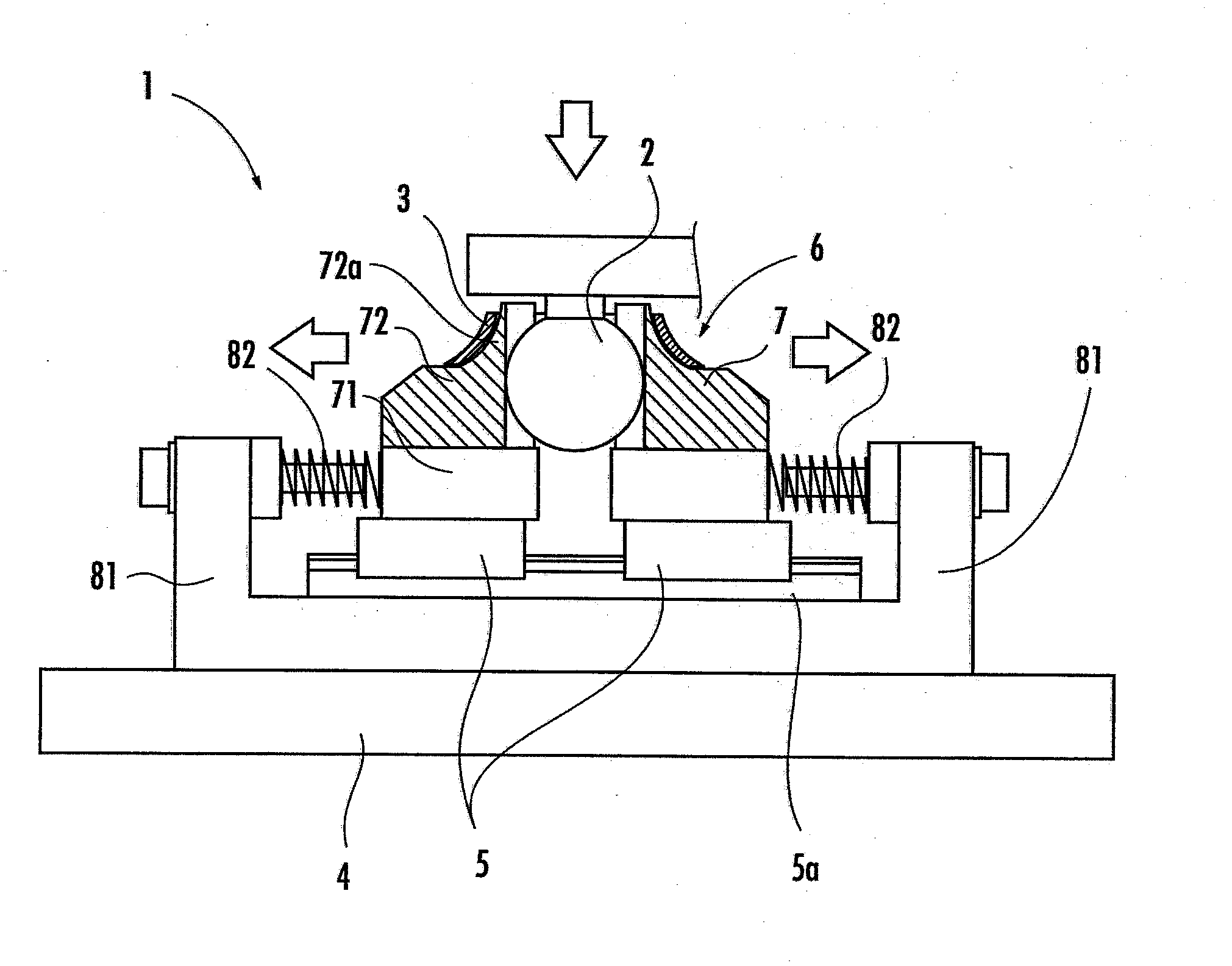

[0029] Reference Figure 1 ~ Figure 4 An embodiment of the ring-shaped seal assembly jig of the present invention will be described. The ring-shaped seal assembly jig 1 of this embodiment is used when assembling the ring-shaped seal 3 to the spherical body 2 of a spherical joint provided on the connecting rod of a pivot assembly (pivot assembly) provided with a wiper link Institutions and so on. The ring-shaped seal assembly jig 1 includes: a base 4; a guide rail 5a arranged on the base 4; and two sliders 5, 5 slidably along the guide rail 5a.

[0030] A semicircular dividing table 7 is attached to each slider 5. A disc-shaped table 6 is formed by bringing two semicircular divided tables 7 into contact with each other, and one annular seal 3 can be placed on the table 6.

[0031] Each dividing table 7 is composed of a semicircular lower part 71 fixed to the slider 5 and a semicircular upper part 72 fixed to the upper surface of the lower part 71. The upper part 72 is made of syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com