A method for opening oblique openings in composite compartments

A cabin section and opening technology, which is applied in the field of oblique openings in composite cabin sections, can solve the problems of large amount of repairs and poor interchangeability, and achieve the effects of improving dimensional accuracy, reducing labor intensity, and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

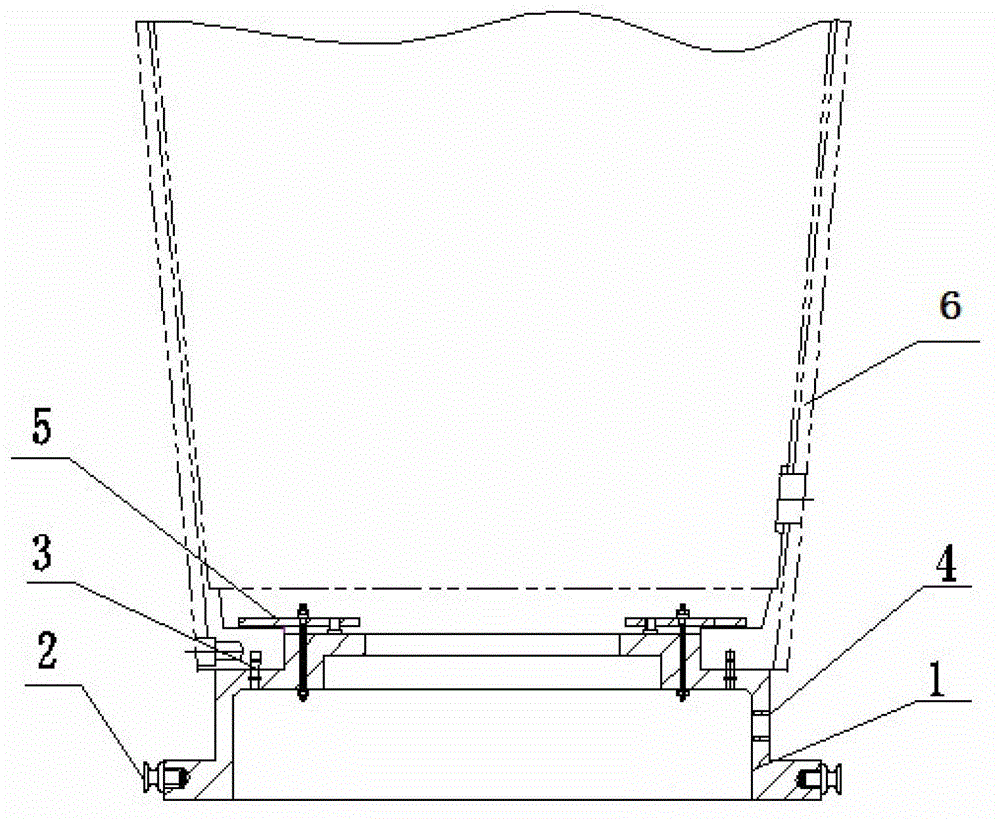

[0038] refer to figure 1 with image 3 , a boring machine fixture with oblique openings in a composite compartment, including a positioning plate 1. One end of the positioning disc 1 is in interference fit with the steel sleeve 4 . The inside of the upper end surface of the positioning disc 1 is interference fit with two cylindrical positioning pins 3 . Two pressing plates 5 are installed on the upper end surface of the positioning disc 1 . Two lifting bolts 2 are installed on both sides of the clip body 1 .

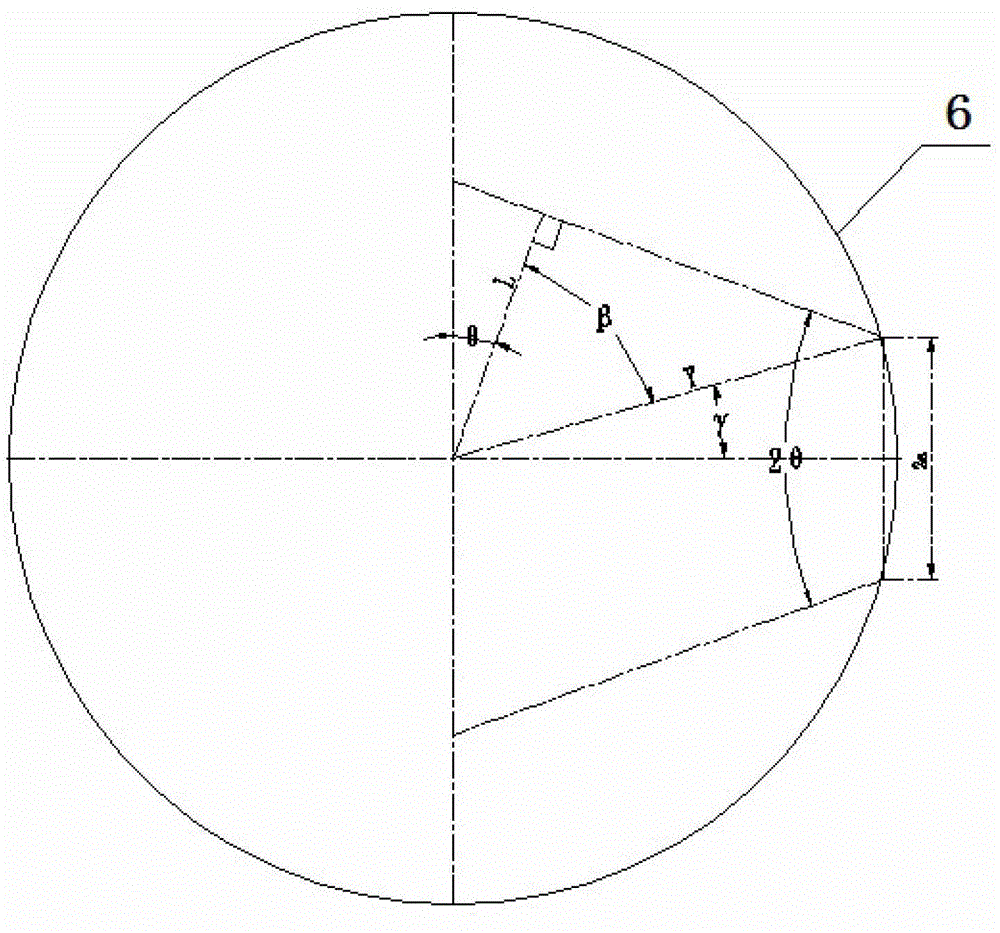

[0039]Open the oblique opening of 40 ° in composite cabin section 6, its process is as follows:

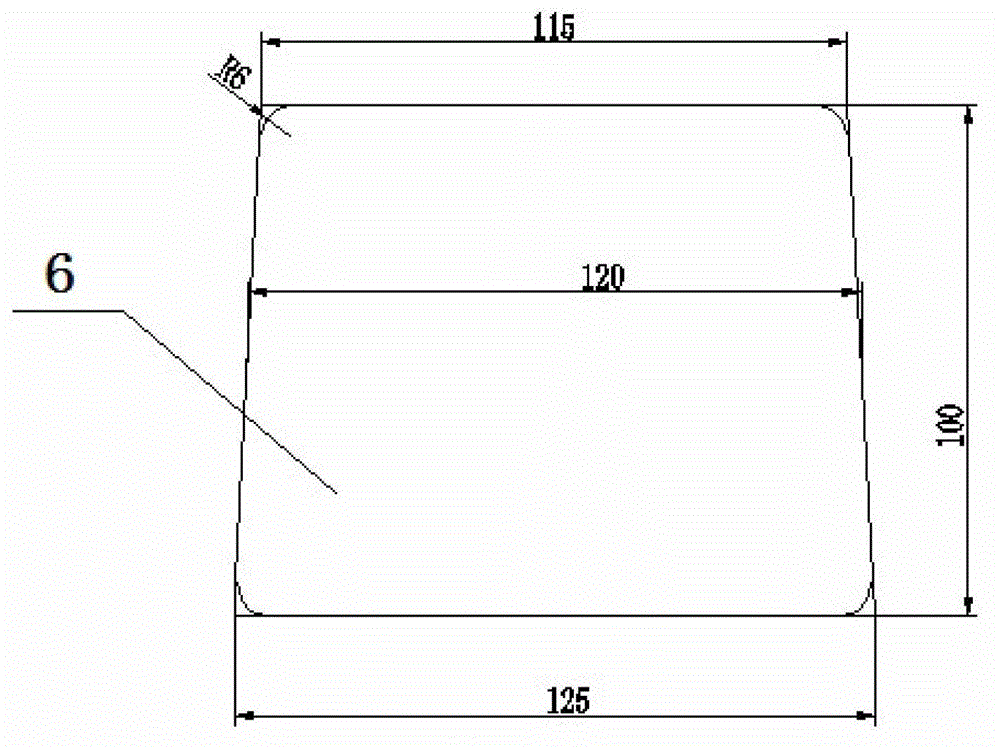

[0040] (1) Calculate the offset distance L value of the boring machine tool: curve equation Y=300(X / 1800)^0.55(930≤X≤1800), opening position b=100, opening angle 2θ=40°, chord length at the opening 2a=120±0.1, find: tool offset distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com