Laser processing clamp of medium substrate and application method thereof

A dielectric substrate and laser processing technology, which is applied in the direction of manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve problems such as damage, dielectric substrate damage, and dielectric substrate bending deformation, so as to achieve convenient operation and solve misoperation Accidents, the effect of laser focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

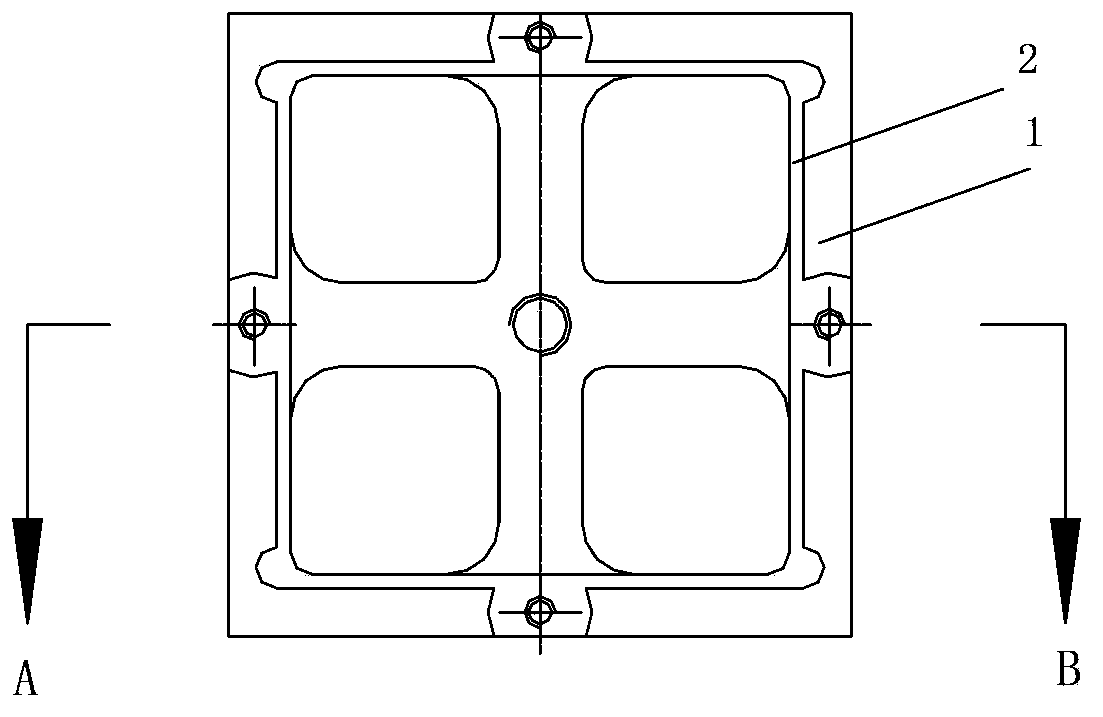

[0033] The dielectric substrate laser processing jig of the present invention will be described in detail below in conjunction with the accompanying drawings.

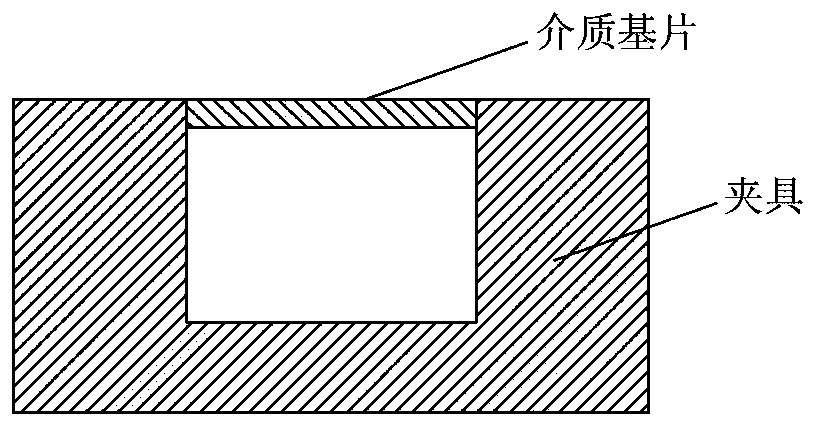

[0034] Such as image 3 As shown, the dielectric substrate laser processing fixture of the present invention includes: the frame is provided with a screw hole 3 for fixing the dielectric substrate, a dielectric substrate 4, and a screw 5 for fixing the dielectric substrate. A recessed rectangular plane area 2, the sunken rectangular plane area 2 is a frame structure in the shape of a "Tian" hollowed out in the middle, and the dielectric substrate 4 is placed in the sunken rectangular plane area 2 with an over-loose fit. The sunken rectangular plane area 2 The depth of the regional depression is equal to the thickness of the dielectric substrate, and the edge of the dielectric substrate is blocked by the head of the dielectric substrate fixing screw 5 .

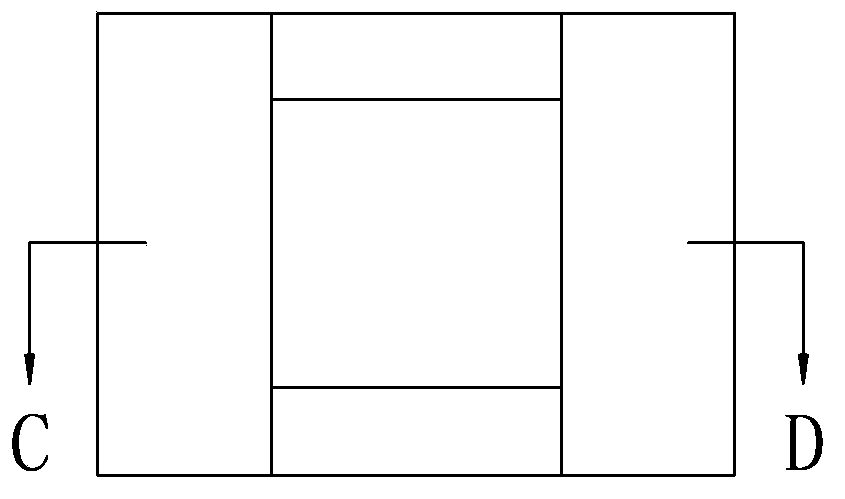

[0035] Such as Figure 4 As shown, an adjustment screw hole 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com