Screw rod and scroll cover of bulking machine

A technology of screw rod and helical sleeve, applied in food forming, food preparation, food science, etc., can solve the problems of high cost of the whole machine, low production efficiency, easy blockage, etc., to increase the area of the conveying channel and increase the output , shorten the effect of the boost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

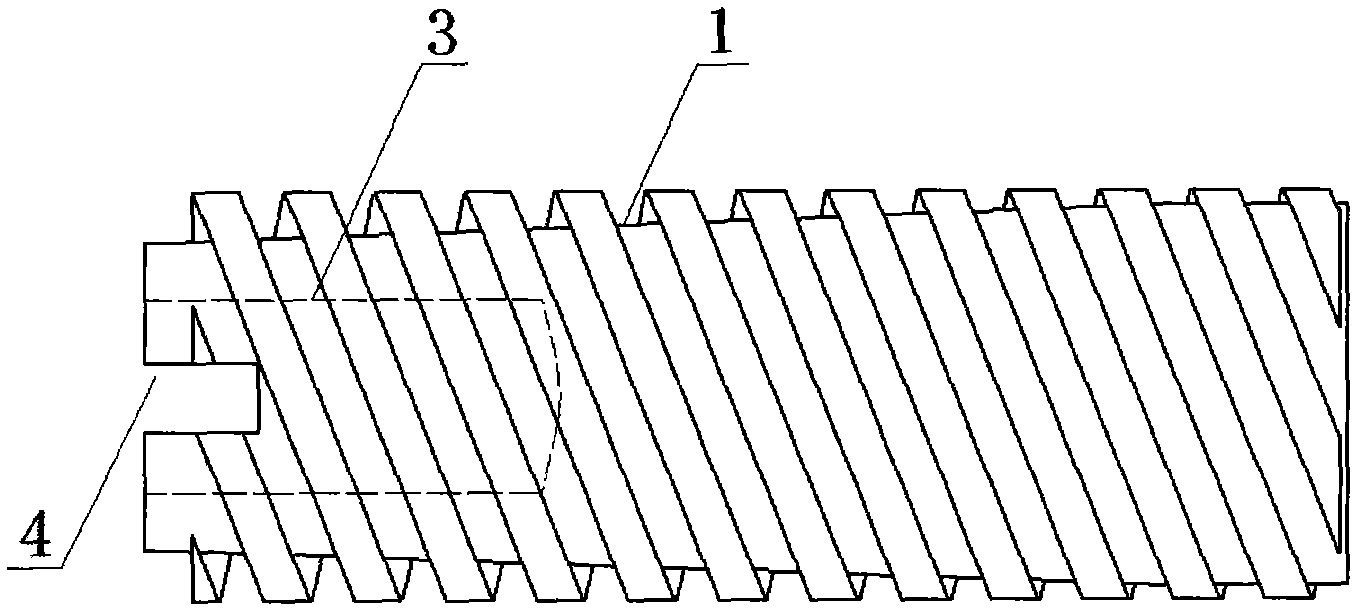

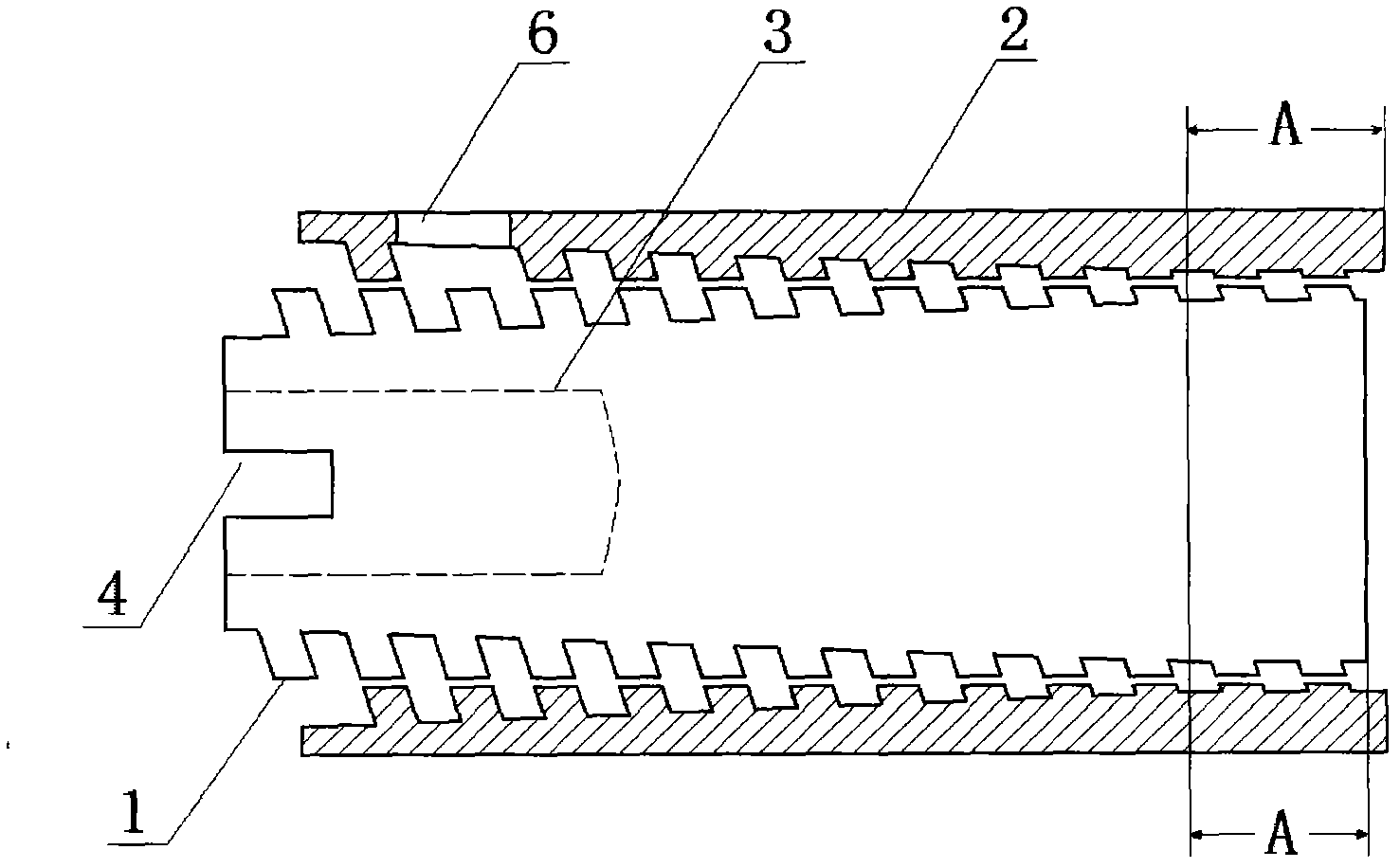

[0019] Such as figure 1 , 2 As shown, the screw rod 1 of the present invention is designed with an outer helix, and the helical sleeve 2 is designed with an inner helix that is consistent with the helical direction of the screw rod 1, and the outer helix of the screw rod 1 and the inner helix of the helical sleeve 2 are all composed of 3-4 Strips isometric spiral composition.

[0020] One end of the screw rod 1 has a shaft hole 3 and a pin opening 4 for connecting with the power shaft 5. The depth of the outer spiral groove gradually becomes shallower from the shaft hole 3 end to the top end, and when it reaches the top of the screw rod 1 , the depth of the outer helical groove remains constant at the minimum size to form a section of plateau A.

[0021] One end of the spiral sleeve 2 has a feed hole 6, and the depth of the inner spiral groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com