Backlight module

A backlight module and light mixing technology, which is applied in the field of backlight modules with light mixing boards, can solve the problems of uneven light mixing, affecting optical quality, and thick body thickness, etc., to achieve both optical quality, shortened intervals, and good light mixing effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

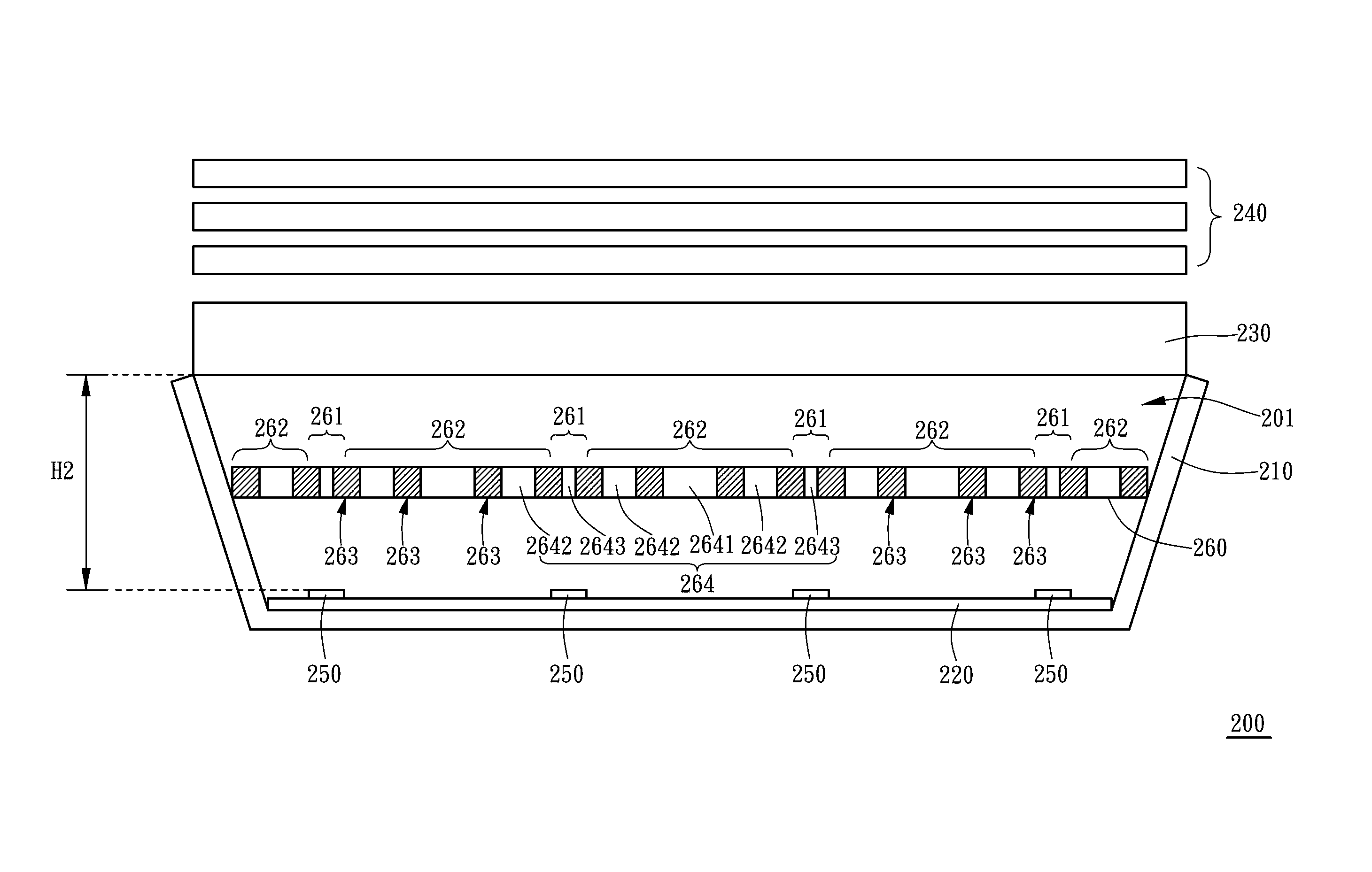

[0048] see figure 2 , figure 2 Shown is a schematic cross-sectional view of the backlight module of the first preferred embodiment of the present invention, the backlight module 200 is a direct-type design, which includes a frame 210, a reflector 220, a diffusion plate 230, a plurality of optical films 240, and a light emitting unit 250 and light mixing plate 260. The inner surface of the frame 210 is provided with a reflective plate 220, and a plurality of light emitting units 250 are arranged on the reflective plate 220. The diffuser plate 230 is connected with the frame 210 and forms a light mixing cavity 201. The light emitting unit 250 and the reflective plate 220 are located in the light mixing cavity 101. Inside. A light mixing plate 260 is added between the light emitting unit 250 and the diffuser plate 230. In this embodiment, the edge of the light mixing plate 260 is fixed to the frame 210, and the light emitting unit 250 is a light-emitting diode (Light-Emitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com