Flexible electric heating sucker rod

A sucker rod and electric heating technology, which is applied in the direction of drill pipe, heating element shape, isolation device, etc., can solve the problems such as the increase of resistivity, and achieve the effects of reducing failure frequency, high overall strength and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

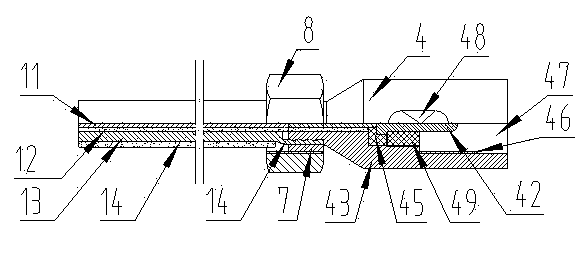

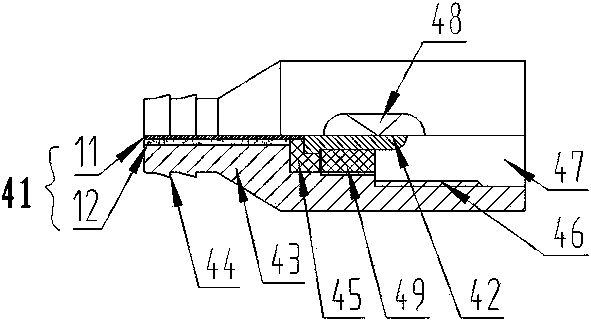

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

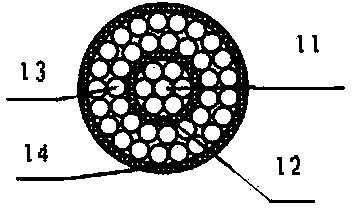

[0027] Such as figure 1 , figure 2 In the shown flexible electric heating sucker rod, the center is a heating copper core wire 11, and the outer layer is a steel wire rope layer 13. Between the steel wire rope layer 13 and the heating copper core wire 11 is an insulating layer 12, and at the end of the flexible electric heating sucker rod A rigid connector 4 is provided, which can be connected to the piston of the oil well pump, and can also be connected to the weighted electric heating rod 2. The rigid connector 4 can play a role of reliable connection conduction and sealing, and the flexible electric heating sucker rod can Cut to any length as needed.

[0028] The distribution power supply of the flexible electric heating sucker rod of the present invention can adopt the IGBT frequency conversion system, such as Figure 9 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com