Process for preparing hexadecyl methyl 2-hydroxyethyl ammonium bromide

A technology of cetyl methyl dihydroxyethyl ammonium bromide and methyl diethanolamine, which is applied in the preparation of amino hydroxy compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of harmful recovery of organic solvents, Difficulties and other problems to achieve good solubilization performance, reduce pollution and the cost of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

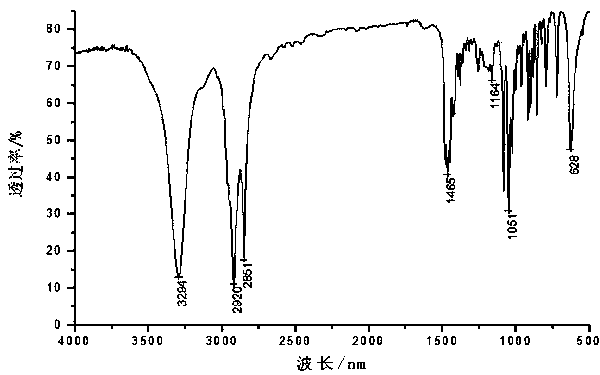

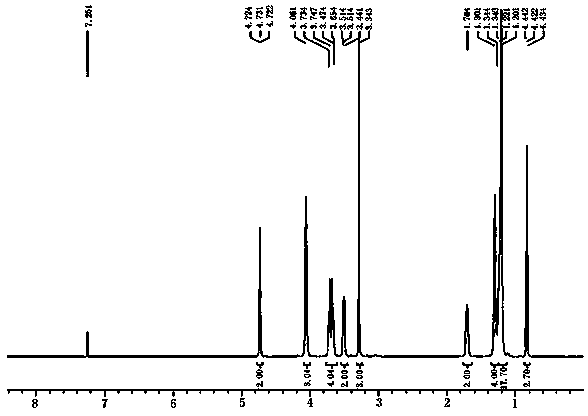

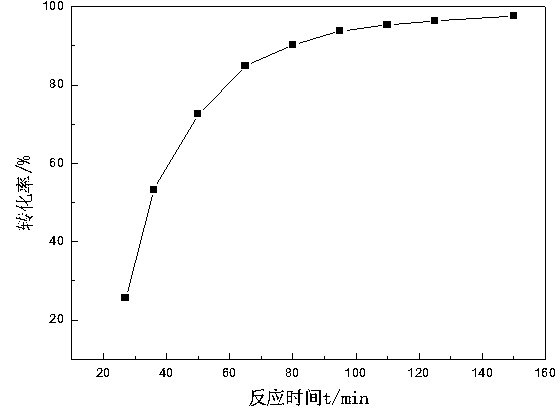

[0027] Weigh N-methyldiethanolamine and bromohexadecane into a three-necked flask equipped with a mechanical stirrer, reflux condenser, and thermometer. The molar ratio of bromohexadecane and N-methyldiethanolamine is 1.1: 1. The reaction temperature is 110°C under heating in an oil bath. After reacting for 110 minutes, the crude product was recrystallized three times with a mixture of ethyl acetate and absolute ethanol, and then suction filtered to obtain bright white crystals, which were obtained after vacuum drying at 50°C. The melting point was determined to be 120.09°C.

Embodiment 2

[0029] Weigh N-methyldiethanolamine and bromohexadecane into a three-necked flask equipped with a mechanical stirrer, reflux condenser, and thermometer. The molar ratio of bromohexadecane and N-methyldiethanolamine is 1.2: 1. React under heating in an oil bath, and the reaction temperature is 120°C. After reacting for 110 minutes, the crude product was recrystallized three times with a mixture of ethyl acetate and absolute ethanol, and then suction filtered to obtain bright white crystals, which were obtained after vacuum drying at 50°C. The melting point was determined to be 121.03°C.

Embodiment 3

[0031] Weigh N-methyldiethanolamine and bromohexadecane into a three-necked flask equipped with a mechanical stirrer, reflux condenser, and thermometer. The molar ratio of bromohexadecane and N-methyldiethanolamine is 0.9: 1. React under heating in an oil bath, and the reaction temperature is 100°C. After reacting for 110 minutes, the crude product was recrystallized three times with a mixture of ethyl acetate and absolute ethanol, and then suction filtered to obtain bright white crystals, which were obtained after vacuum drying at 50°C. The melting point was determined to be 121°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com