Overturning fast moving trailer

A fast-moving, overturning technology, applied to motor vehicles, goods transport vehicles, vehicles used for freight, etc., can solve the problems of increasing on-site preparation time, vibration, and difficult replacement of axles, etc., to reduce preparation time and difficulty , Reduce manufacturing cost, simple, convenient and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

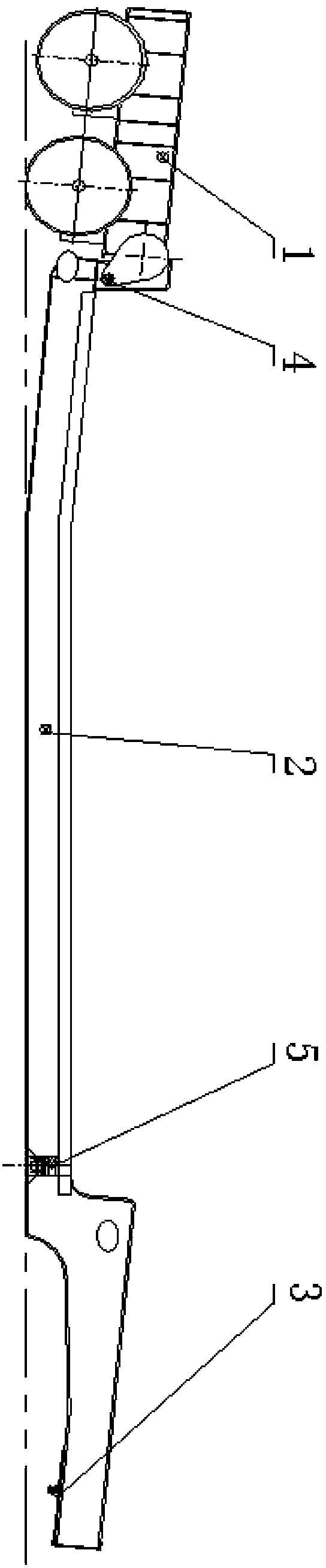

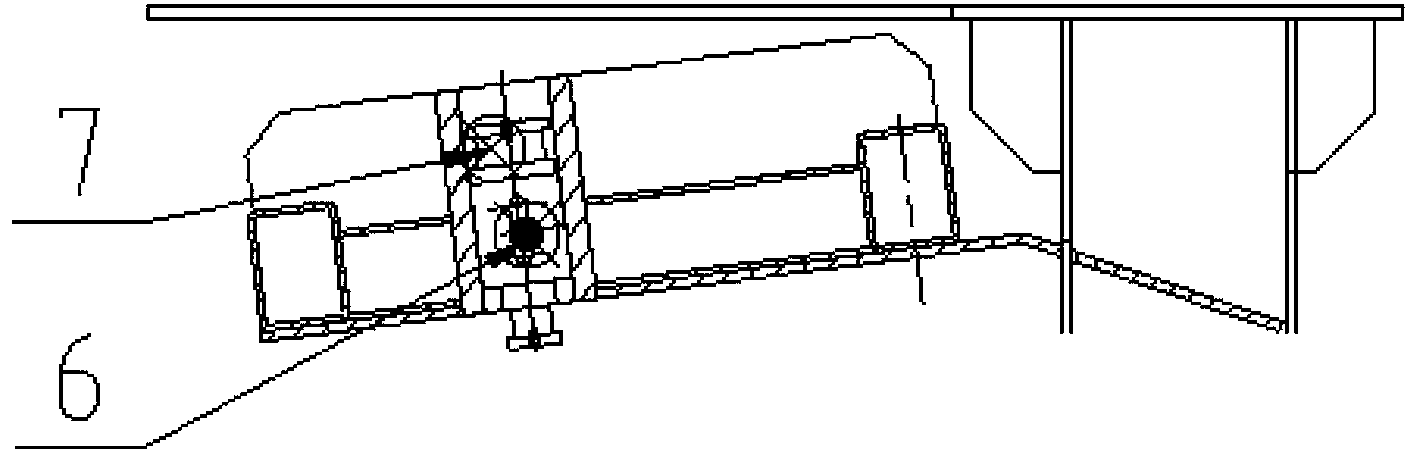

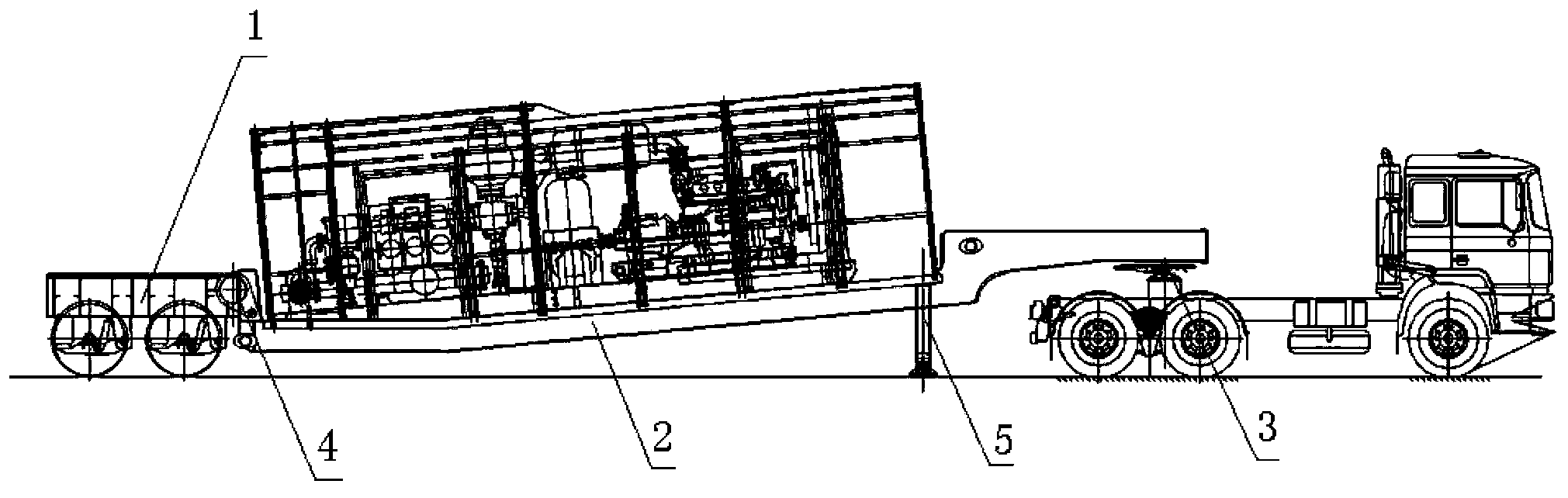

[0019] Such as Figure 1-4 As shown, the trailer described in this embodiment includes an axle suspension vehicle assembly 1, a skid seat 2 and a turning pin device 3, and the axle suspension vehicle assembly 1 is connected to the skid seat 2 through a connecting pin 4. The two sides of the front part of the skid base 2 are respectively provided with a lifting support device 5, and the front end of the skid base 2 is connected with the flipping traction pin device 3 through a pin shaft 6, and the flipping traction pin device 3 is provided with a reversible U-turn The traction pin 7 installed, the two ends of the traction pin 7 have different specifications and sizes; the axle suspension vehicle assembly 1 is single bridge, double bridge or multi-bridge; the connecting pin 4 is a movable pin; the skid seat 2 There is a concave structure in the middle, and the bottom surface of the concave structure is a turning surface; the traction pin 7 is fixed by the pin shaft 6; the specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com