Pin shaft machine

A shaft pin machine and shaft pin technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of unreasonable design, low degree of automation, waste of raw materials, etc., to save production materials, high degree of automation, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

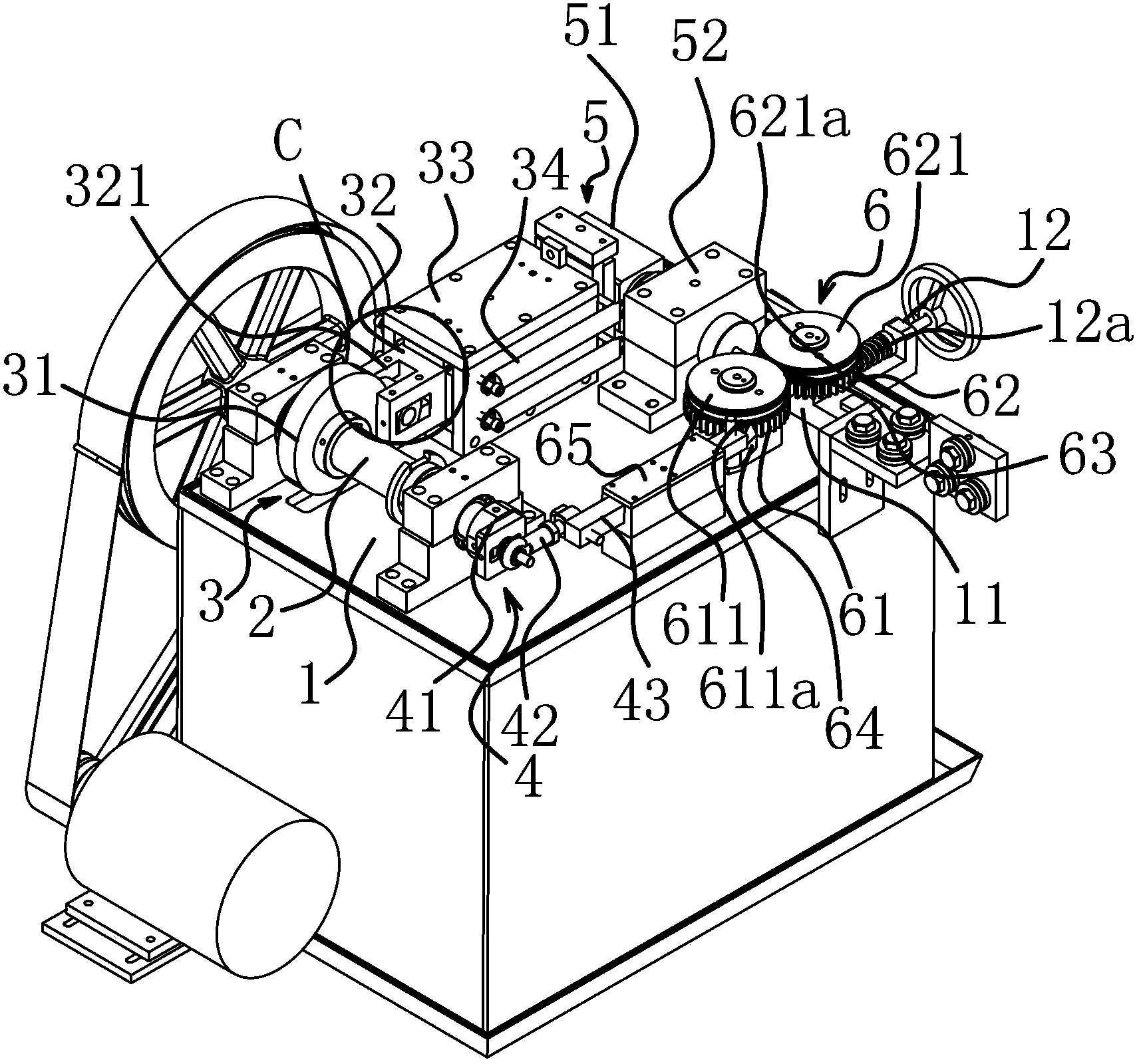

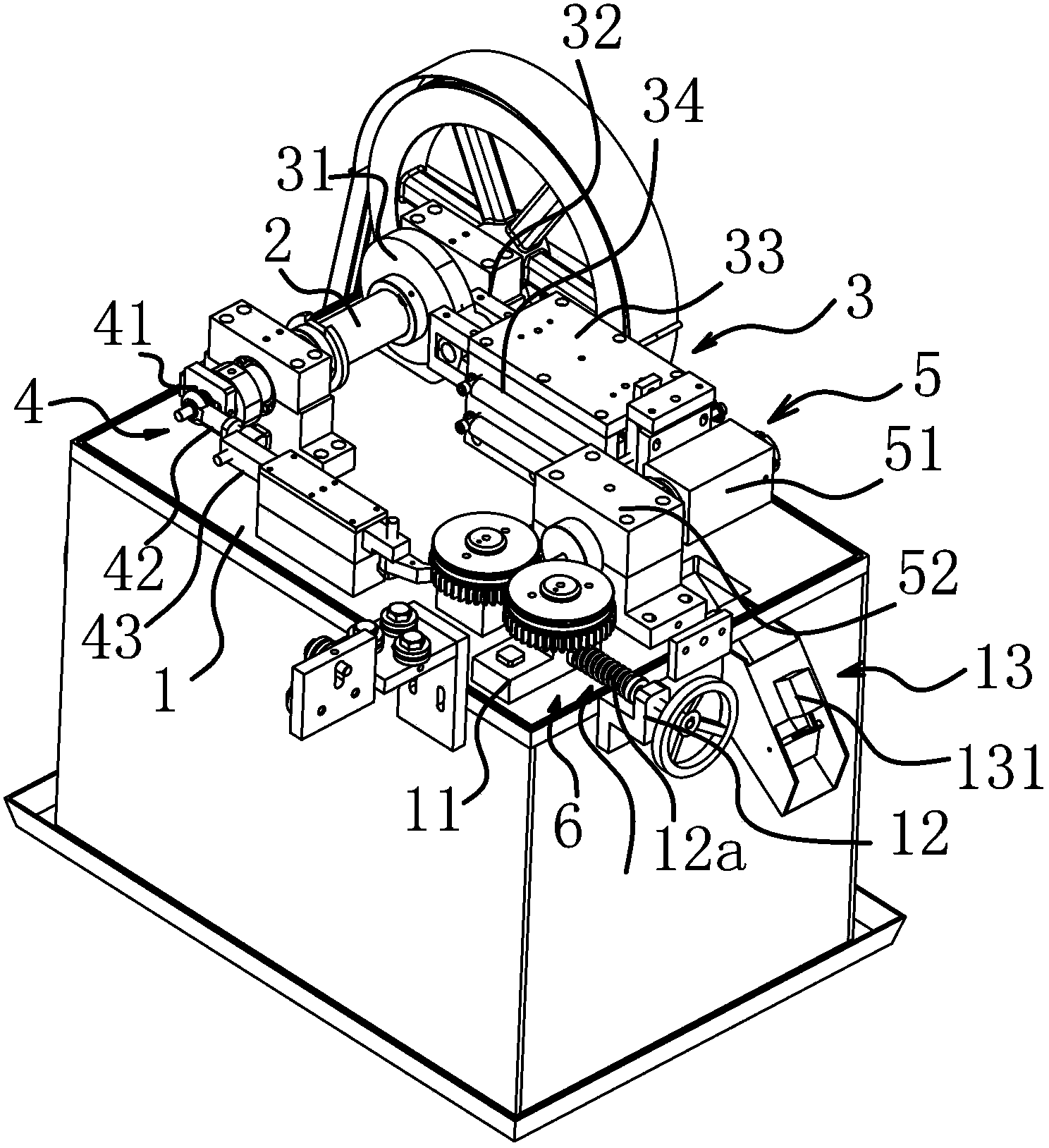

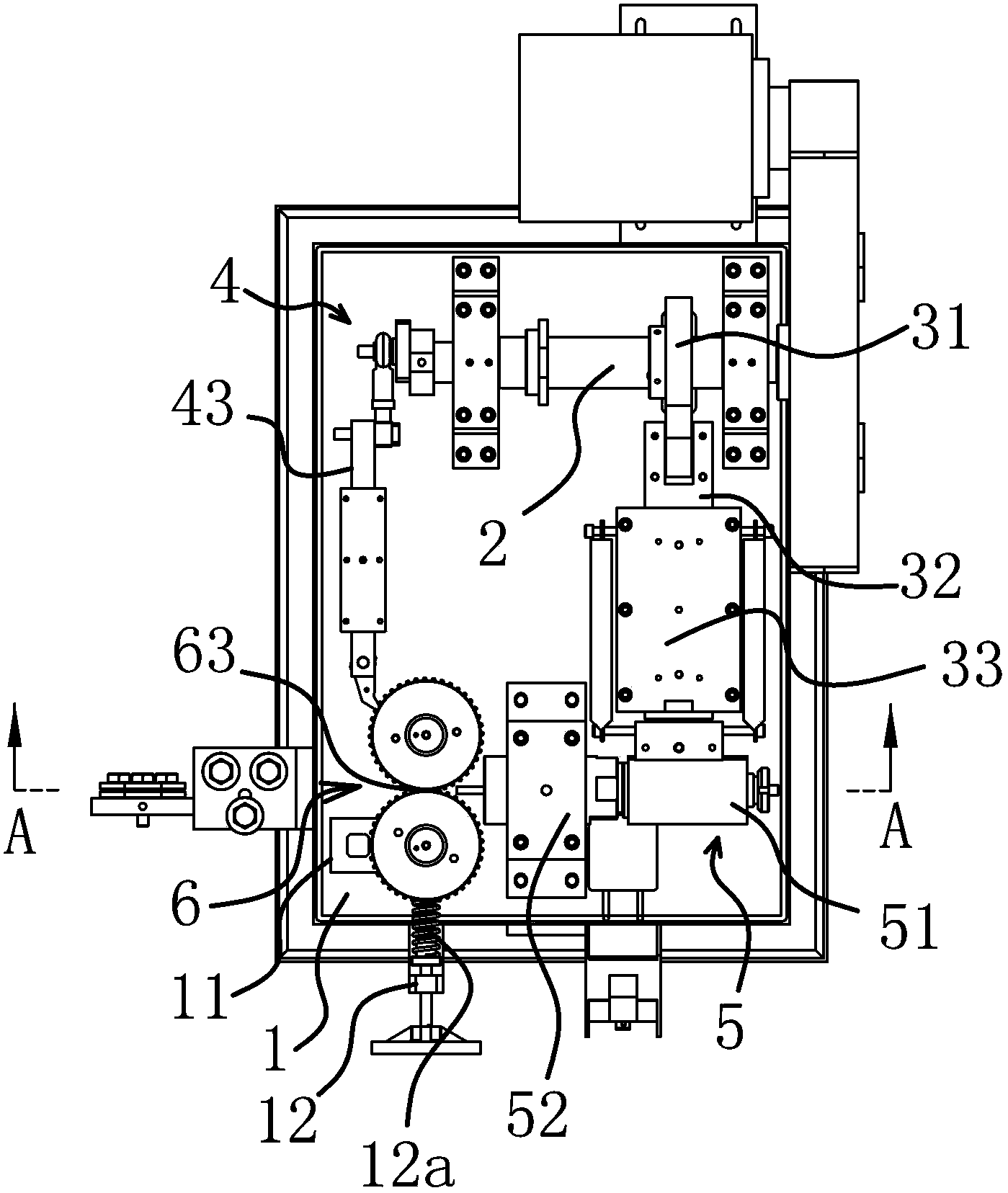

[0031] Such as Figure 1-6 As shown, the shaft pin machine includes a working platform 1, on which a driving shaft 2 arranged horizontally and capable of rotating in the circumferential direction is provided, and on the driving shaft 2 is provided a first driving assembly 3 distributed axially along the driving shaft 2 And the second driving assembly 4, the first driving assembly 3 is connected with the cutting mechanism 5 and can drive the cutting mechanism 5 to work, the second driving assembly 4 is connected with the feeding mechanism 6 and can drive the feeding mechanism 6 to work, and when the drive shaft 2 When rotating, feeding mechanism 6 and cutting mechanism 5 work alternately. Cutting mechanism 5 is located at one side of feeding mechanism 6 and can receive the strip-shaped material input by feeding mechanism 6 and cut the strip-shaped material into a shaft pin.

[0032] The cutting mechanism 5 includes a fixed knife cylinder assembly 51 and a movable knife cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com