Tool for assembling spring clamp of automotive oil pipe

A spring clip and oil pipe technology, used in workpiece clamping devices, metal processing, manufacturing tools, etc., can solve problems such as flying out, personal injury to workers, deformation of spring clips, etc., to achieve convenient and fast operation, improve production efficiency and safety. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

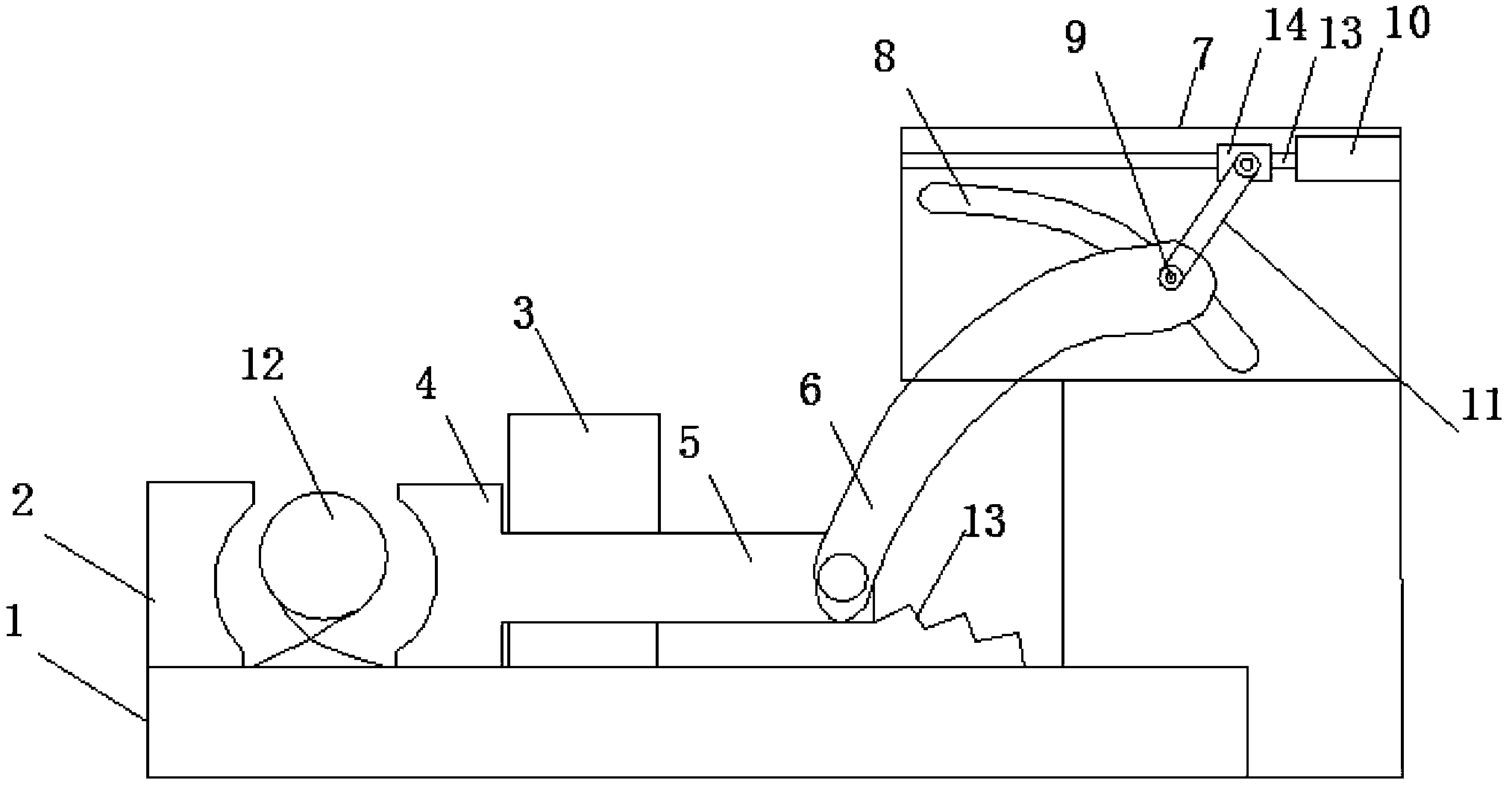

[0011] like figure 1 As shown, the tooling used for the assembly of automobile oil pipe spring clips includes a base 1, a fixed clamping die 2 is fixed at one end of the base 1, a guide block 3 is also fixed on the base 1, and the movable clamping die 4 is arranged opposite to the fixed clamping die 2. And to the opposite side are all concave surfaces, the spring clamp 12 is placed between the two concave surfaces, an axial slide bar 5 is provided on the movable clamping mold 4, the slide bar 5 passes through the guide hole in the guide block 3 and a push The rod 6 is movably connected by a pin bolt, a guide seat 7 is provided on the side of the base 1, and an arc-shaped guide groove 8 is provided in the guide seat 7, and a sliding pin 9 that can slide along the guide groove is provided in the guide groove 8, and the push rod 6 The other end is movably connected with the sliding pin 9, and the guide seat 7 is provided with an axial drive mechanism, which is movably connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com