Method for manufacturing major diameter enclosed impeller

A closed impeller, large-diameter technology, applied in the field of aerospace equipment manufacturing, can solve the problems of thin wall thickness of closed impeller, easy to cause accidents, affecting the structure and working performance of the impeller, etc. Hidden danger and the effect of ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

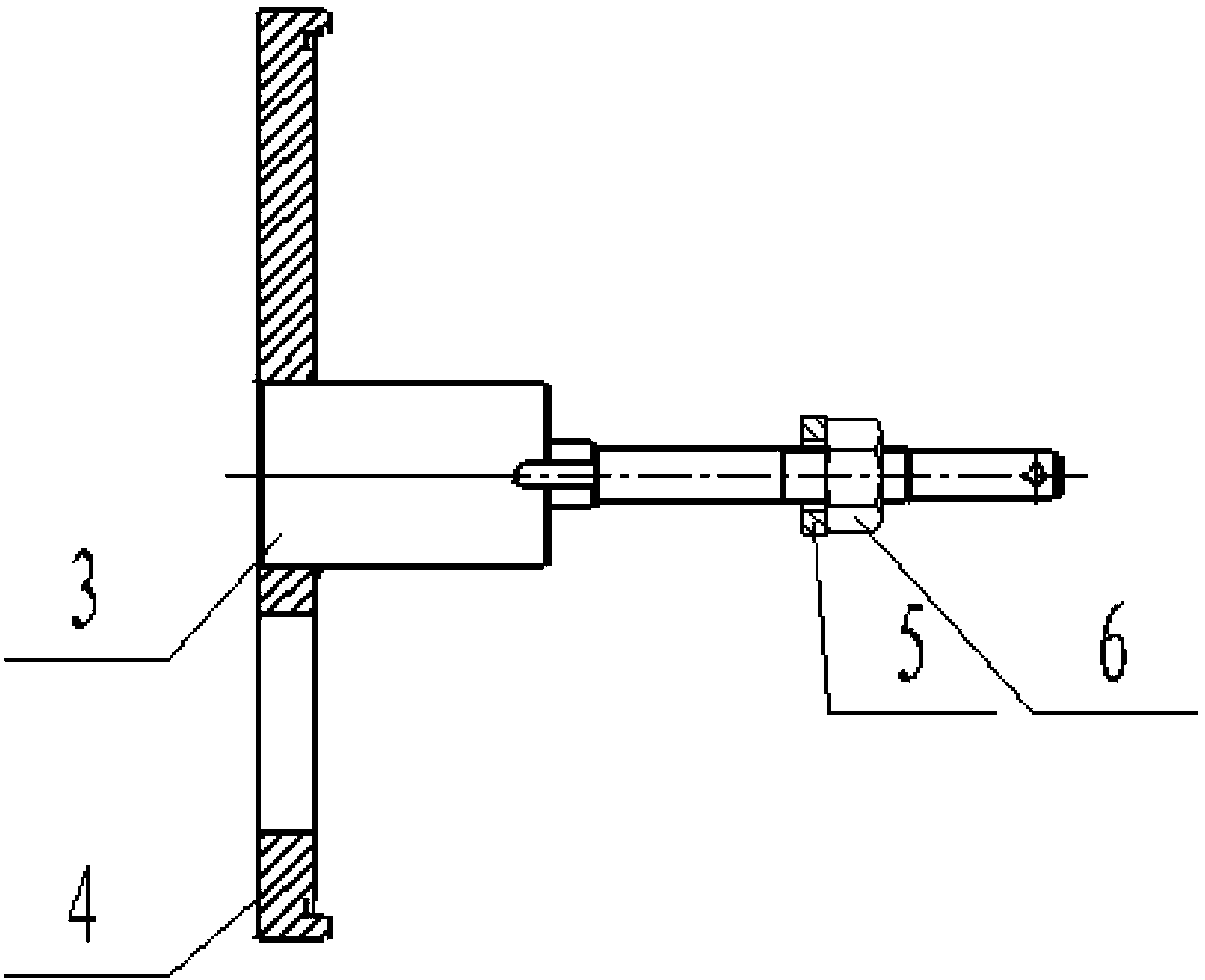

[0035] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

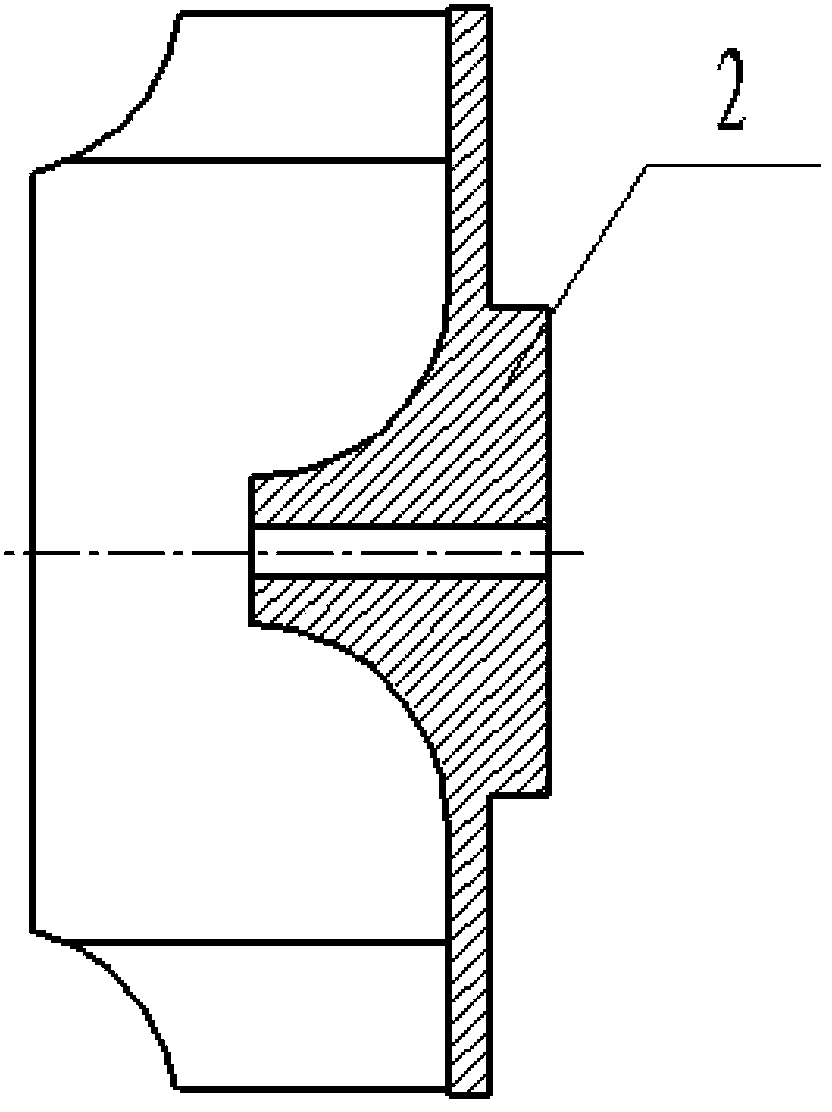

[0036] Such as Figure 1-6 Shown, a kind of method for manufacturing large-diameter closed impeller described in the invention described in the present invention, it comprises the following steps:

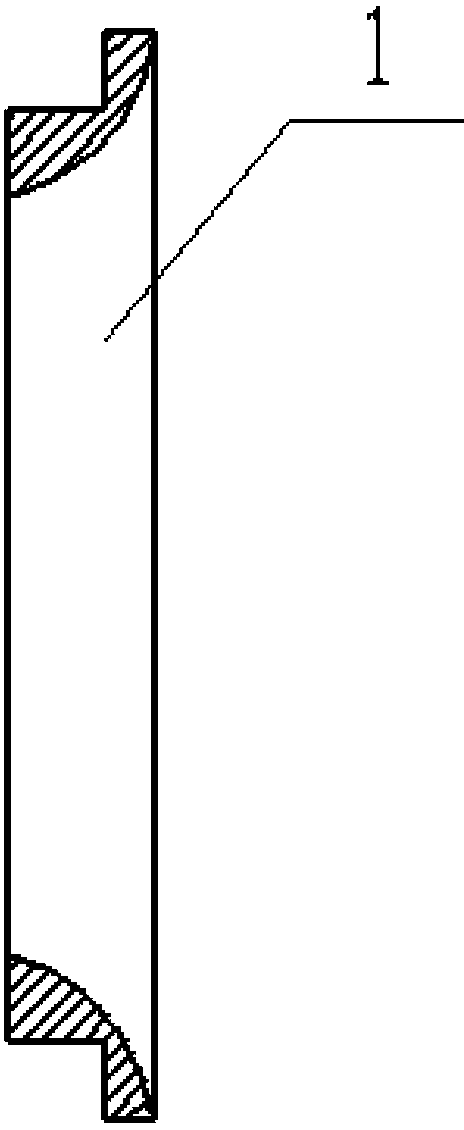

[0037] Step 1: Rough machining of the impeller cap;

[0038] Process the shape of the impeller cap 1 except for the arc surface, and reserve a stepped 8-10 mm machining allowance on the stepped side, and process three technological steps on the outer ring of the impeller cap and the impeller mating surface, so that the impeller cap When the cover 1 and the impeller are assembled together, the unilateral gap is controlled within 0.1mm, which plays a pre-positioning role; the purpose of the reserved process step is to enable the impeller cap and the impeller to be assembled together to play a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com