Motor with brake

A technology for brakes and motors, which is applied in the directions of brake actuators, electric components, and mechanical energy control, and can solve the problems of inclination of the stator for brakes and low installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

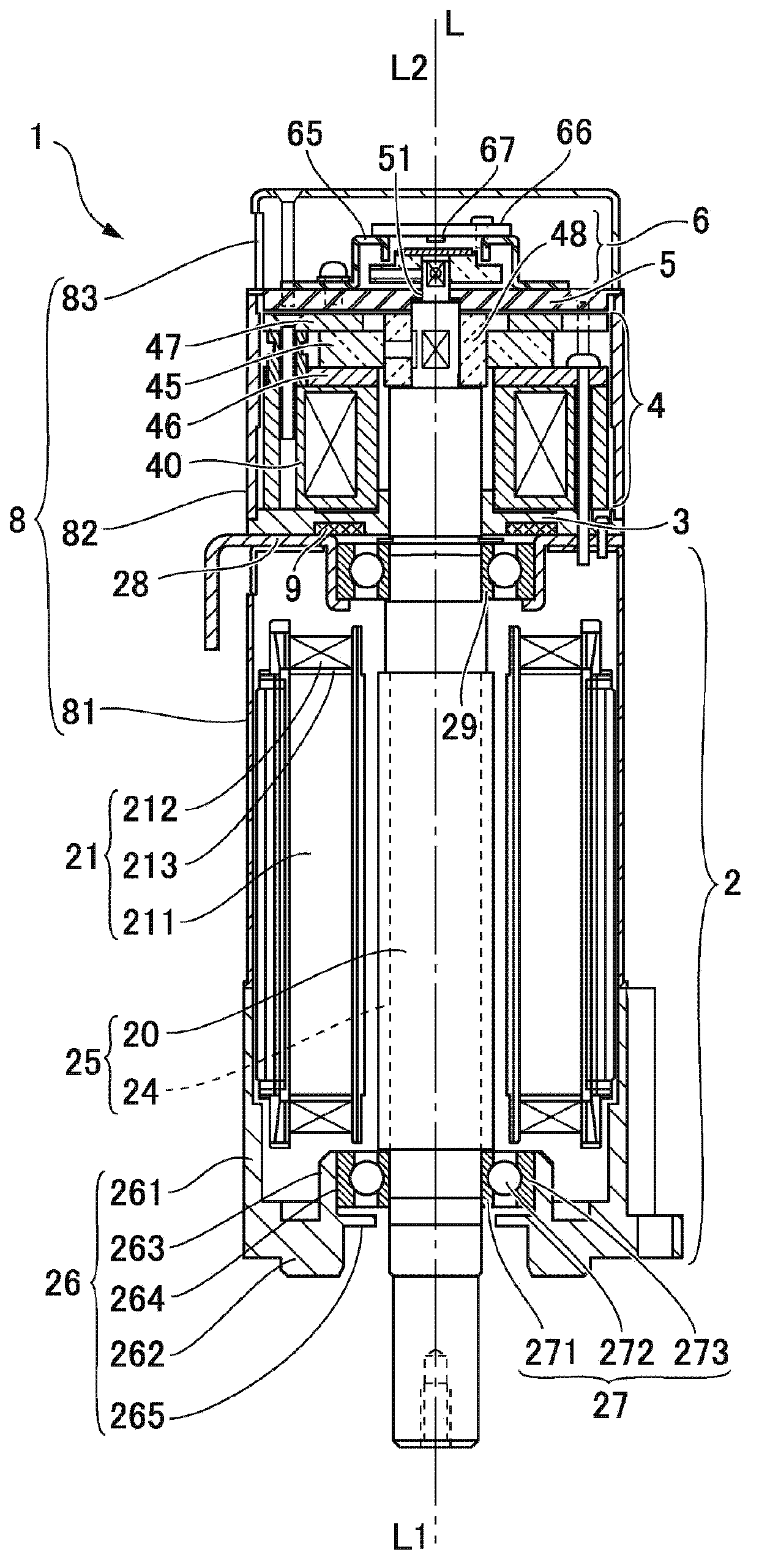

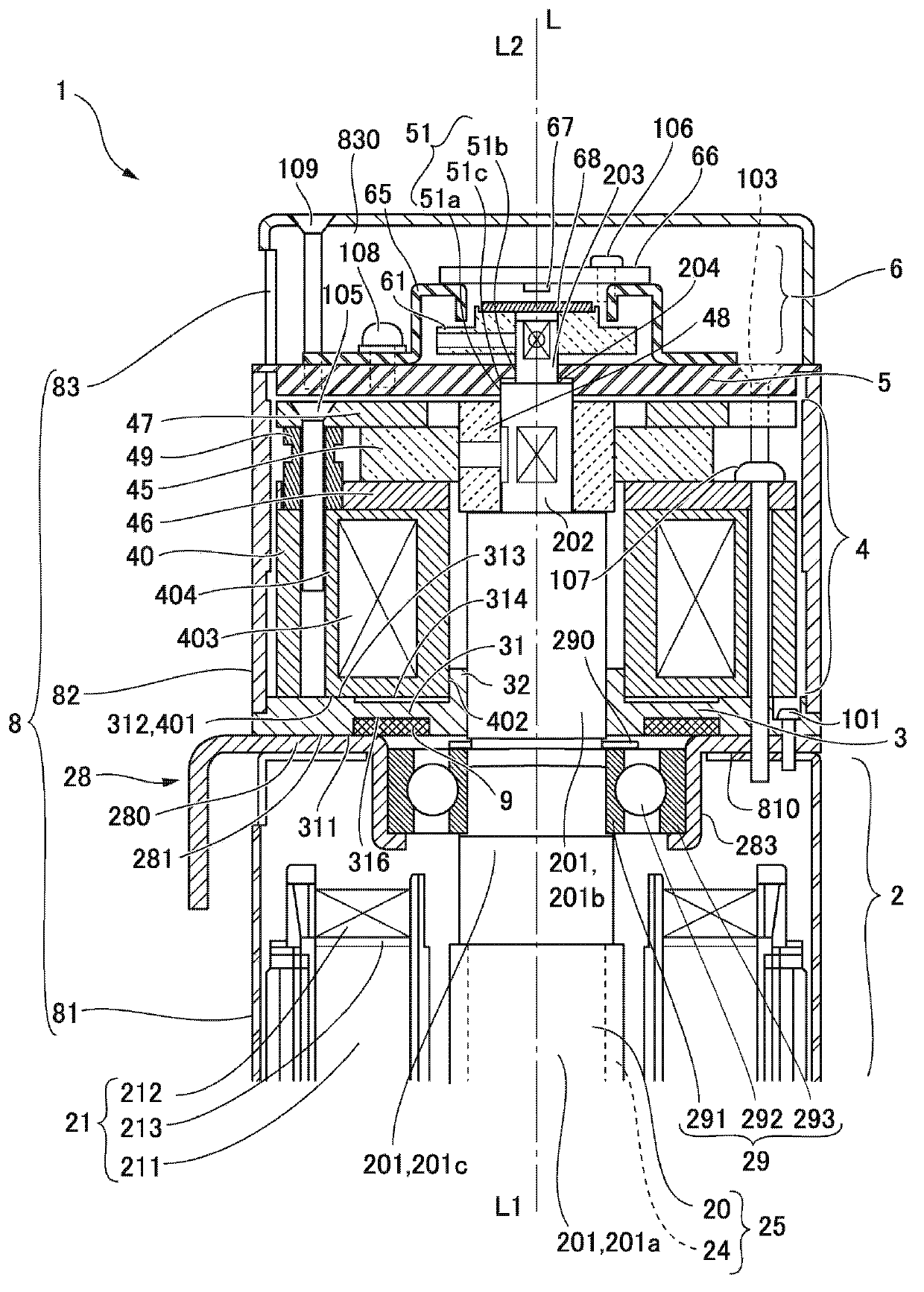

[0049] Hereinafter, an example of a motor with a brake using the present invention will be described with reference to the drawings. In the following description, when indicating the direction of the motor axis L, the side where the motor shaft protrudes is referred to as the output side L1 , and the side opposite to the side where the motor shaft protrudes is referred to as the anti-output side L2 . In addition, in the drawings, the screws 101, 103, and 107 are shown at overlapping positions, but the screws 101, 103, and 107 are arranged at different positions in the circumferential direction.

[0050] (The overall structure of the motor)

[0051] figure 1 is a sectional view of a motor with a brake using the present invention, figure 2 It is an enlarged cross-sectional view showing essential parts of the motor with brake to which the present invention is applied.

[0052] Such as figure 1As shown, in the motor 1 with brake of this example, the motor unit 2 and the brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com