LED chip oblique cutting method, LED light-emitting element and LED lighting device

A LED chip, oblique cutting technology, applied in the direction of electrical components, electrical solid devices, semiconductor/solid device manufacturing, etc., can solve the problems of high comprehensive cost, high complexity, and infeasibility, so as to improve efficiency, reduce heat loss, Effect of Luminous Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described below with reference to the accompanying drawings. The same reference numerals denote the same parts in the drawings.

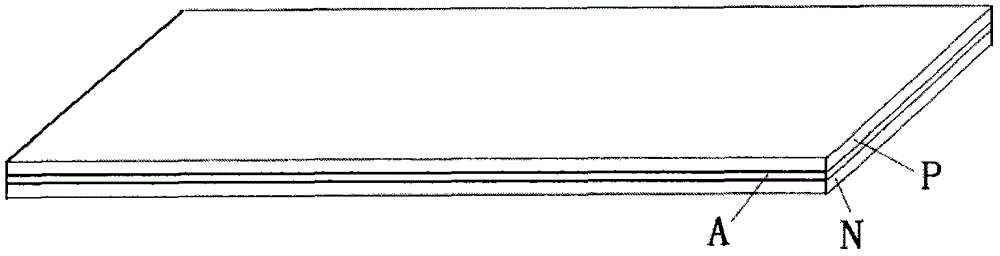

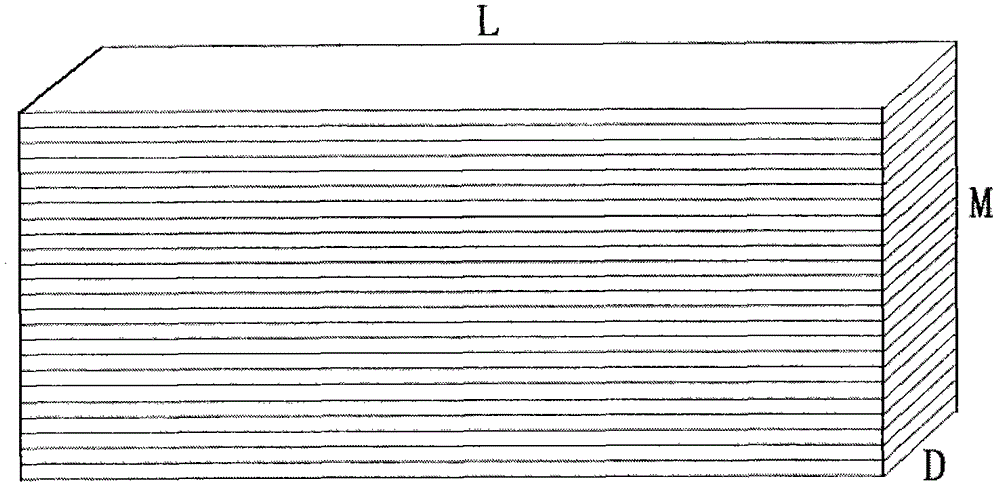

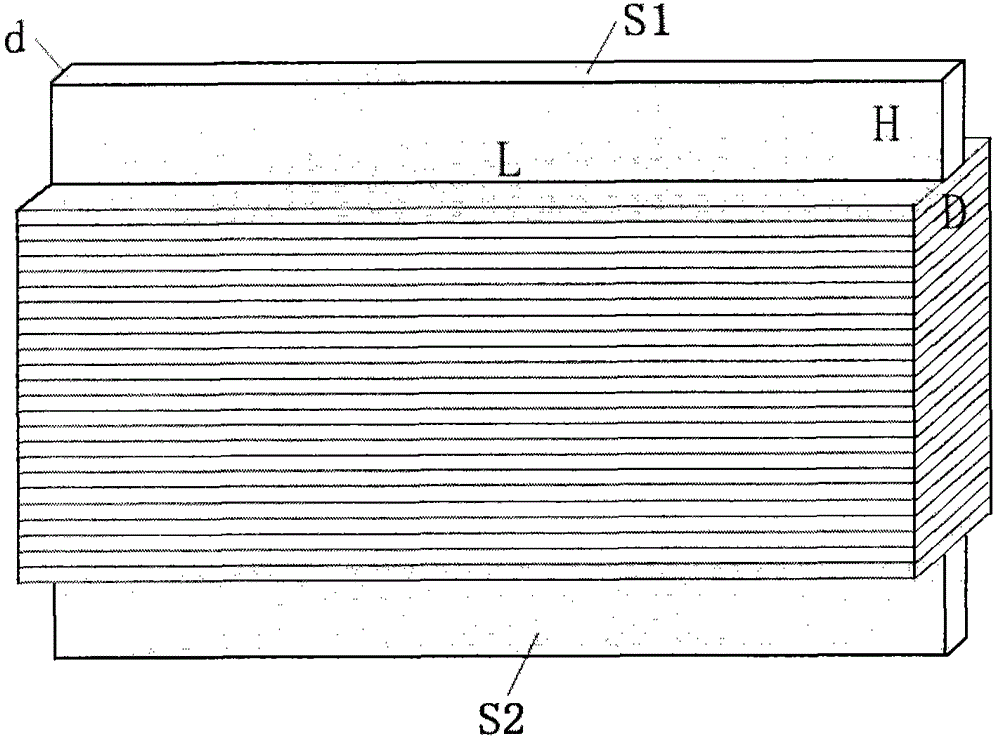

[0021] First, select n (n is an integer greater than 1) LED chips of the same type and remove the substrate of each LED chip. refer to figure 1 As shown, the substrate is first peeled off for large-sized chips. If the symbol P in the figure represents a P-type semiconductor material layer and the symbol N represents an N-type semiconductor material layer, an active light-emitting layer A is formed at the contact surface of the two layers. That is, the commonly known pn junction layer, which emits light in the case of forward conduction. Subsequently, a transparent electrode layer with a thickness of about 1.5 microns is directly bonded on both sides by epitaxy technology or crystal expansion technology, such as transparent Al 2 o 3 electrode layer. exist figure 1 The transparent electrode lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com