Object defect check system and method

A defect detection, article technology, applied in the direction of measuring devices, material analysis by optical means, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

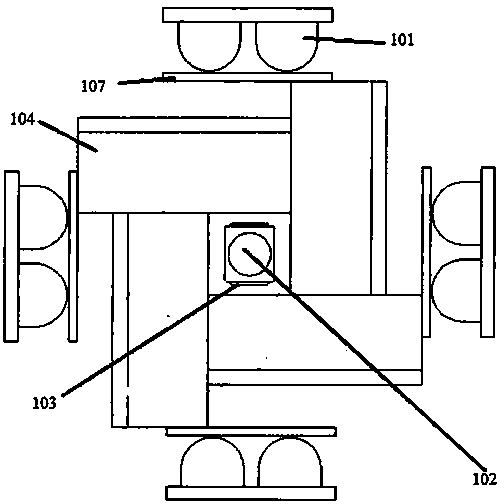

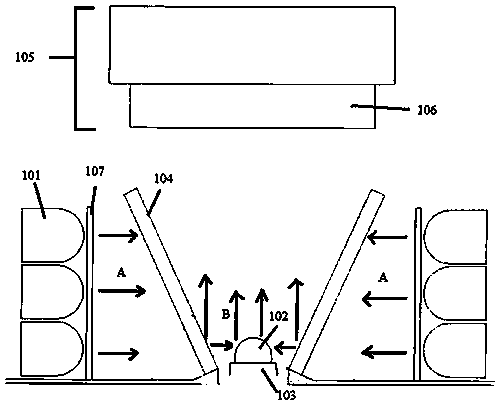

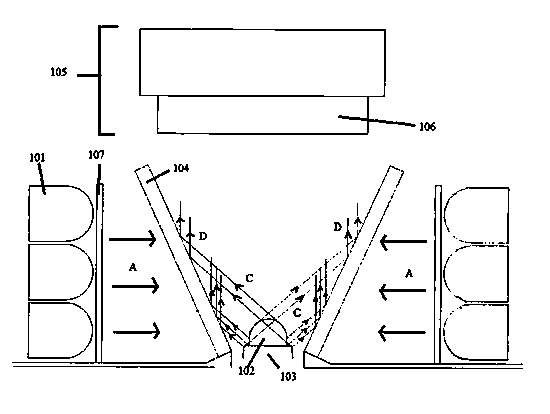

[0015] The present invention discloses a defect detection system 100 for an item 102, which includes a light source 101 generally located on the side of the item 102 and used to project light to illuminate part of the item 102; a platform 103 for supporting the item 102; an optical sensor 105; and a reflection device 104 arranged between the light source 101 and the object 102, inclined to the light source 101 at a certain angle, used to receive the light image reflected from the illuminated part of the object, and project the light image to the light sensor 105 On; there, the light sensor 105 will record the reflected light image, and convert the light image into data for defect analysis.

[0016] An LED lens, preferably of dome shape, is an item of interest 102 for testing its light transmission and / or sensory quality. Defects on the lens surface or inside of an LED lamp affect both its performance and its aesthetic value. Defects on or within the object 102 include any one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com