Phase-change heat accumulation unit

A phase change heat storage and phase change heat storage material technology, applied in the field of phase change heat storage units, can solve the problems of inconvenient use, low heat utilization efficiency, inability to realize on-demand configuration of heat storage capacity, etc., and achieve convenient installation and efficient storage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

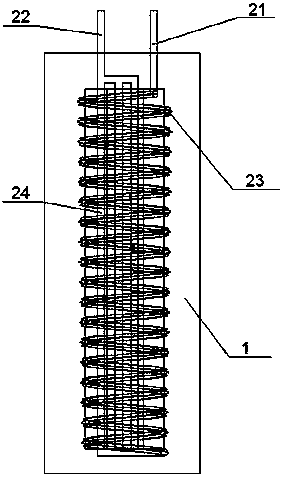

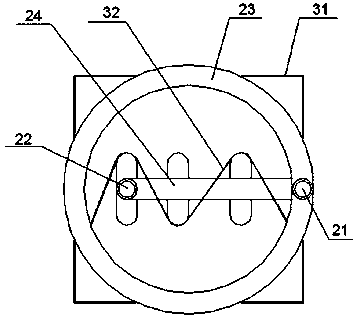

[0036] refer to figure 1 , in this embodiment, the phase change heat storage unit includes a container 1, which is a cylindrical tube, and a heat exchanger is arranged in the container 1.

[0037] Such as figure 1 As shown, the heat exchanger includes an inlet 21 and an outlet 22. The inlet 21 is connected to an input pipe 23, and the outlet 22 is connected to an output pipe 24. There are three output pipes 24, which are connected and merged at the outlet 22.

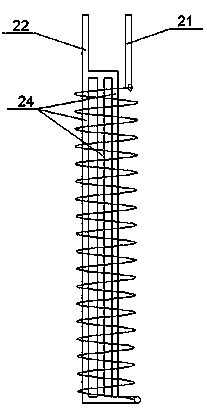

[0038] In this embodiment, the input pipe 23 is a spiral coil, and the output pipe 24 can be arranged outside the spiral coil, or arranged in the coil of the spiral coil. The output pipe 24 is configured as a corrugated pipe.

[0039] After simplifying the spiral coil input pipe 23, the structure of the heat exchanger in this embodiment is as follows: image 3 shown.

[0040] The gap between the heat exchanger and the container is filled with a phase change heat storage material, taking paraffin / graphite composite p...

Embodiment 2

[0047] refer to Figure 4 , in this embodiment, the phase change heat storage unit is set with double heat exchangers, each heat exchanger exists independently, the first heat exchanger input pipe 231 is connected to the first heat exchanger inlet 211, and the first heat exchanger The output pipe 241 is connected to the inlet and outlet 221 of the first heat exchanger; the input pipe 232 of the second heat exchanger is connected to the inlet 212 of the second heat exchanger, and the output pipe 242 of the second heat exchanger is connected to the inlet and outlet 222 of the second heat exchanger.

[0048] The number of input pipes of the first heat exchanger and the second heat exchanger can be the same or different, such as Figure 4 As shown, there are two output pipes 241 of the first heat exchanger, and one output pipe 242 of the second heat exchanger, but as required, there may be one, two, three or more.

[0049] In this embodiment, both the input pipe 231 of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com