Preparation method of super absorbent polymer (SAP)

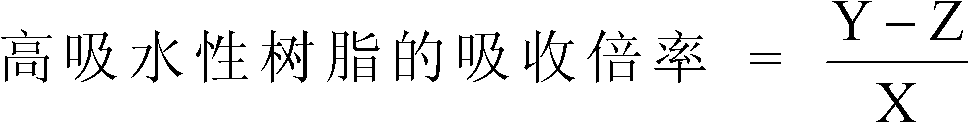

A super absorbent resin, the technology of preparation method, applied in chemical instruments and methods, applications, organic fertilizers and other directions, can solve the problems of energy consumption and manufacturing cost, complex manufacturing process, decreased applicability, etc., to achieve the best water absorption properties, increase The effect of simple process technology and production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the superabsorbent resin of embodiment 1 comprises the following steps:

[0034] (1) Take 10.42g of 48wt% sodium hydroxide aqueous solution and 0.77g of calcium hydroxide in a 100mL Erlenmeyer flask, then add 3g of starch (purchased from China Taiwan Weidan Enterprise Company) and 10g of deionized water and stir for 30 minutes , after starch gelatinization, add 3g acrylamide (purchased from China Taiwan Jingming Chemical Co., Ltd.) and 22.4g deionized water and stir for 30 minutes, then slowly add 30g acrylic acid (sourced from Taiwan Plastic Industry Co., Ltd. company) to neutralize to obtain a reaction monomer solution; wherein 35mol% of acrylic acid is neutralized into acrylate.

[0035] (2) Add 0.046 g of ethoxylated trimethylolpropane triacrylate (ethoxylated TMPTA) into the above reaction monomer solution and stir to obtain a reaction solution, and maintain its temperature at 20°C.

[0036] (3) Add 0.016g L-ascorbic acid, 0.2g sodium per...

Embodiment 2

[0040] In addition to changing the amount of sodium hydroxide aqueous solution and calcium hydroxide in this step (1) to 17.70g and 2.15g respectively (wherein 65mol% of acrylic acid is neutralized to acrylate), the preparation method of Example 2 and Example 2 1 is the same.

Embodiment 3

[0042] Except that the consumption of aqueous sodium hydroxide solution and calcium hydroxide of this step (1) is changed to 15.63g and 2.32g respectively (wherein the acrylic acid of 60mol% is neutralized as acrylate), and in the starch paste of this step (1) The preparation method of Example 3 was the same as that of Example 1, except that 3 g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS, purchased from Jingming Chemical Company, Taiwan, China) was additionally added after the reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com