Method for monitoring cutting machining on a workpiece

A technology for cutting and inspecting workpieces, used in metal processing, metal processing equipment, welding/welding/cutting items, etc., and can solve problems such as incomplete separation of workpieces, cutting errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

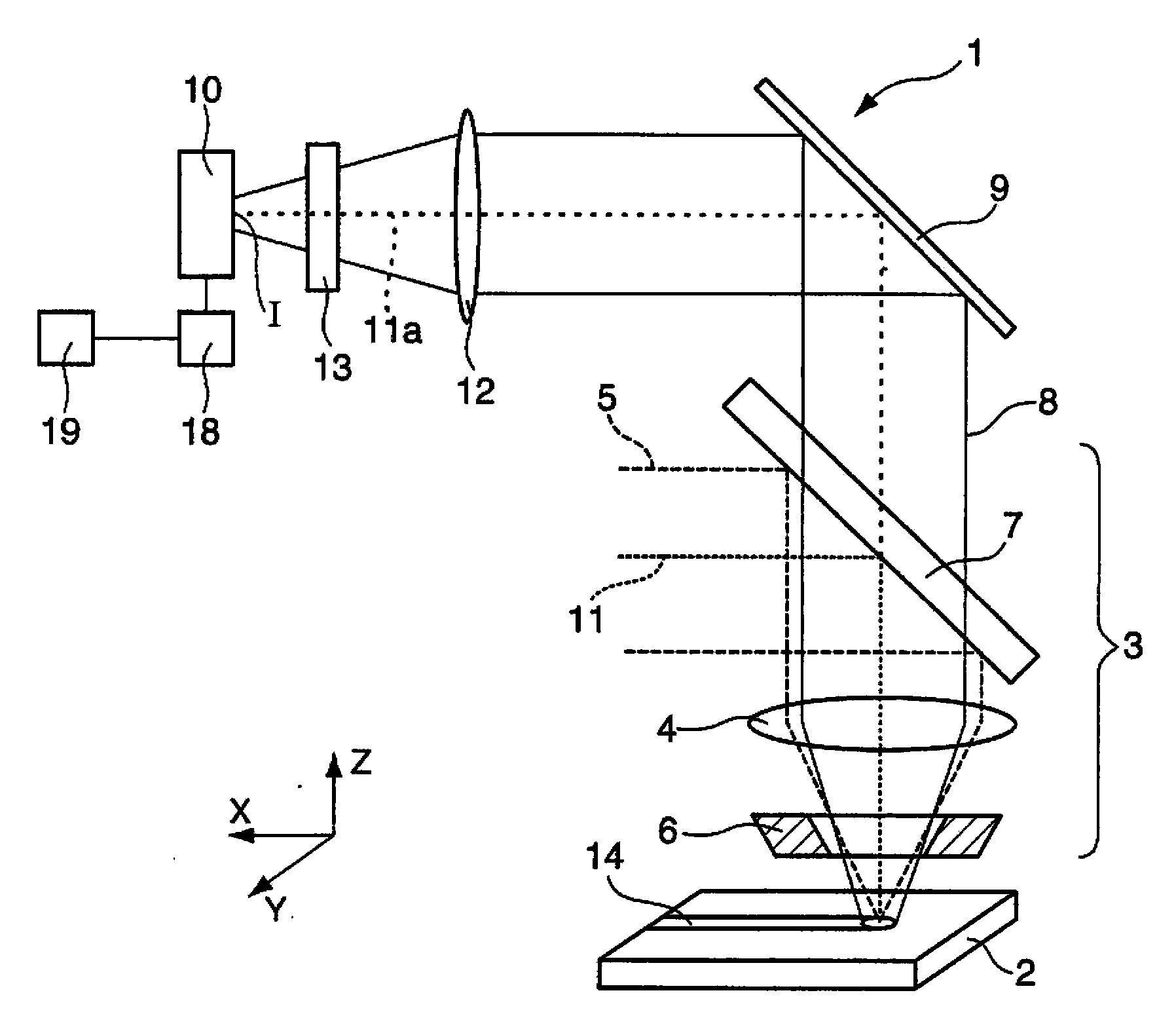

[0026] figure 1A detail of a laser processing machine 1 for cutting a workpiece 2 is shown, which includes a processing unit in the form of a laser processing head 3 . The laser processing head 3 has a focusing lens 4, which is made of zinc selenide and serves to divert CO 2 - laser beam 5 focused, the CO 2 - the laser beam is powered by (not shown) CO 2 -Laser generation. In the case of the present invention, the turning mirror 7 is configured to be partially transmissive and will convert the incident CO 2 - the laser beam 5 (with a wavelength of about 10 μm) reflects and transmits the radiation 8 from the workpiece 2 which is important for process monitoring, said radiation 8 being in the wavelength range, namely in the example of the invention between about 550 nm and 2000 nm between. It is understood that the laser processing machine 1 described here can also have a (not shown) solid-state laser beam source (such as a disk laser or a fiber laser), which has a radiatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com