A rotor frequency conversion redundancy speed adjusting device

A speed regulating device and rotor technology, applied in the direction of electrical components, control systems, AC motor control, etc., can solve the problems of high liquid water temperature, production line impact, power consumption, etc., and achieve less equipment, digitalization, energy saving, environmental protection, and use Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

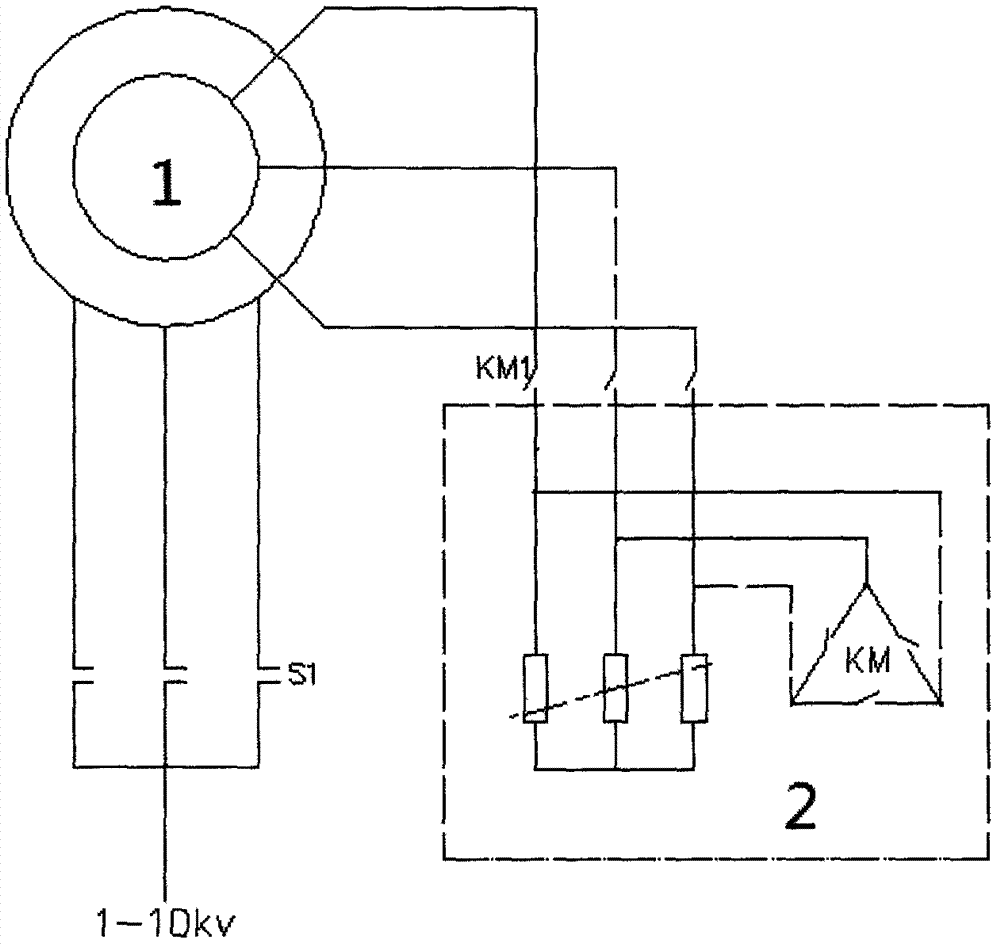

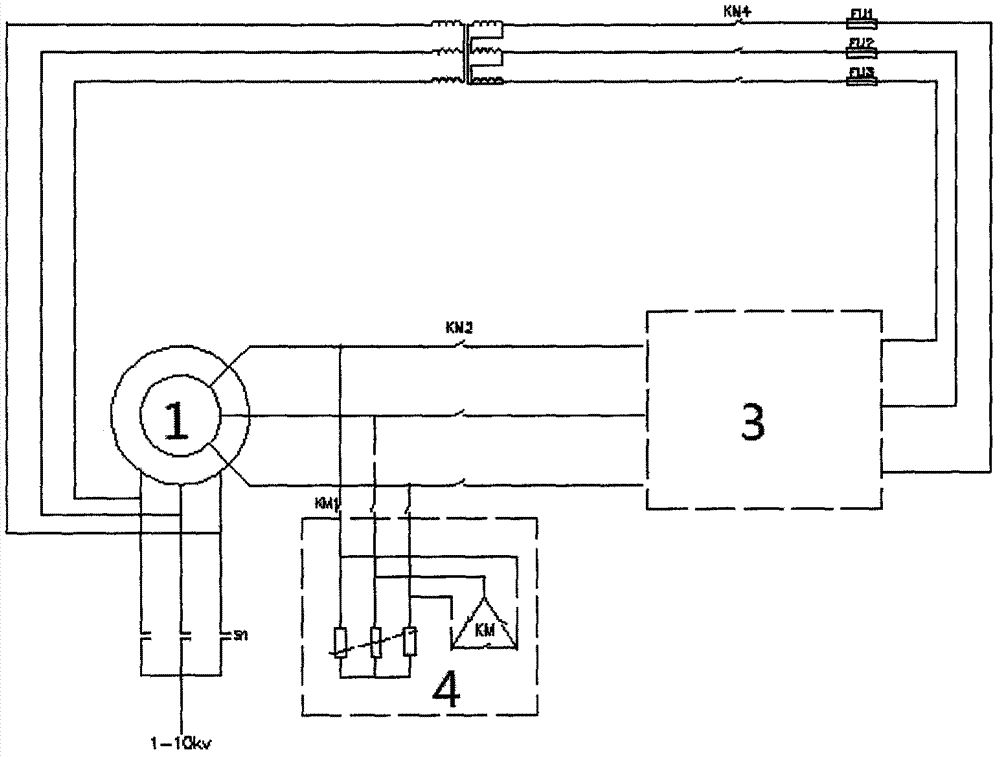

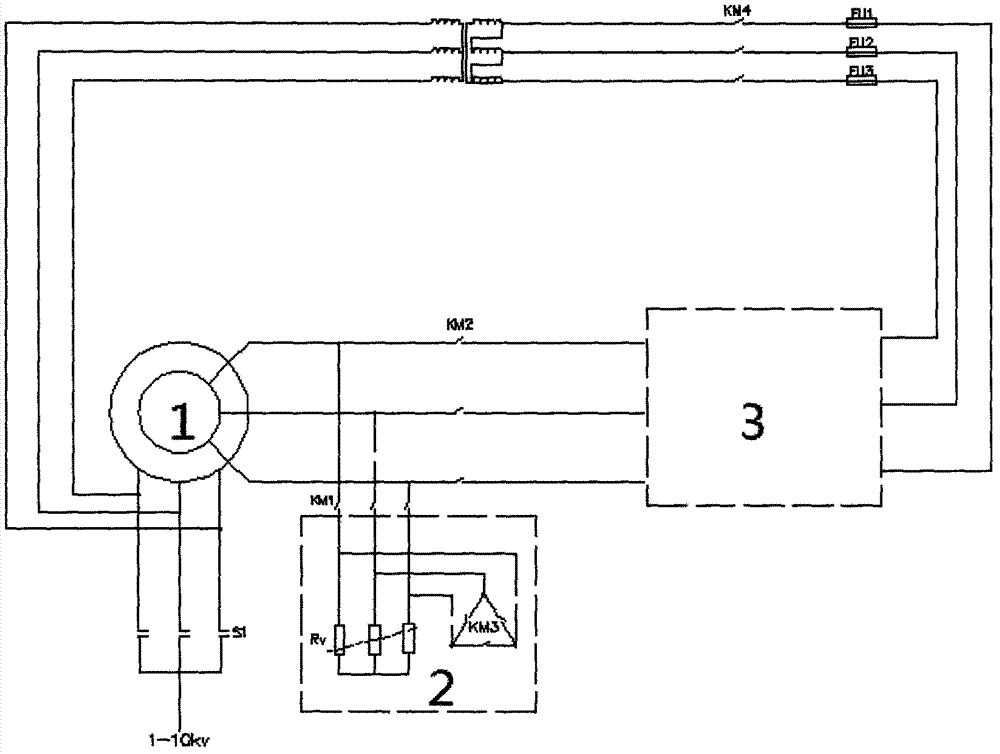

[0016] Such as figure 1 As shown, the liquid resistance is adjusted by adding appropriate electrolytic powder to pure water. The more electrolytic powder added, the smaller the resistance. When the motor (1) is started, the electrode plate is located at the same height as the upper limit switch. At this time, the resistance of the liquid resistance externally connected to the rotor winding is the largest, the starting torque is large, the starting current is small, and the motor (1) starts smoothly. This type of product is improved on the basis of the traditional liquid resistance starter (2), and already has the function of speed regulation. The speed regulation control system consists of hardware and software. The hardware includes the core components PLC, tachometer, electrode plate travel motor, control electrical appliances, etc. Among them, the PLC is mainly used for logic control, speed value acquisition, adjustment calculation, etc., and is the core of the speed contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com