Intelligent tracking solar-powered semiconductor temperature difference generation device

A thermoelectric power generation and intelligent tracking technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of large floor space and low energy conversion rate, and achieve the effect of small floor space and reduced power generation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

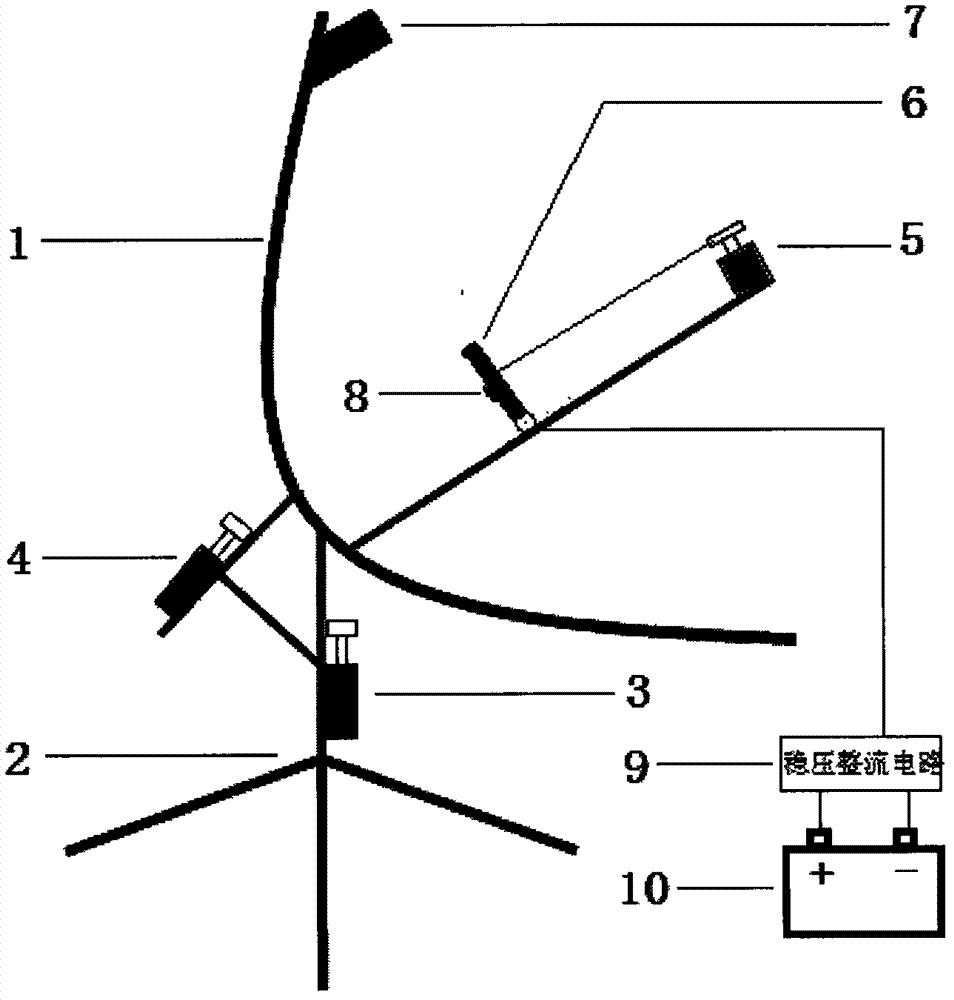

[0009] In the figure, 1-reflector, 2-automatic adjustment base, 3-horizontal adjustment motor, 4-vertical adjustment motor, 5-height adjustment motor, 6-power generation module, 7-angle detection device, 8-temperature sensor, 9 - voltage stabilizing rectifier module, 10 - storage battery.

[0010] When in use, first install the curved reflector 1 on the automatic adjustment base 2, the horizontal adjustment motor 3 controls the rotation of the reflector in the horizontal plane, the vertical adjustment motor 4 controls the rotation of the reflector 1 in the vertical plane, and the height adjustment motor 5 Control the power generation module 6 to move on the straight line where the light focus is; when the device starts to work, the angle detection device 7 detects the incident angle of sunlight, adjusts the reflector 1 through the horizontal adjustment motor 3 and the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com