Pin-out structure of relay convenient for installation of complete machine

A relay and lead-out technology, applied in the field of relays, can solve the problems of pin collision and the decrease of the sealing performance of the relay, and achieve the effects of ensuring the sealing performance, reducing the difficulty of operation and improving the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

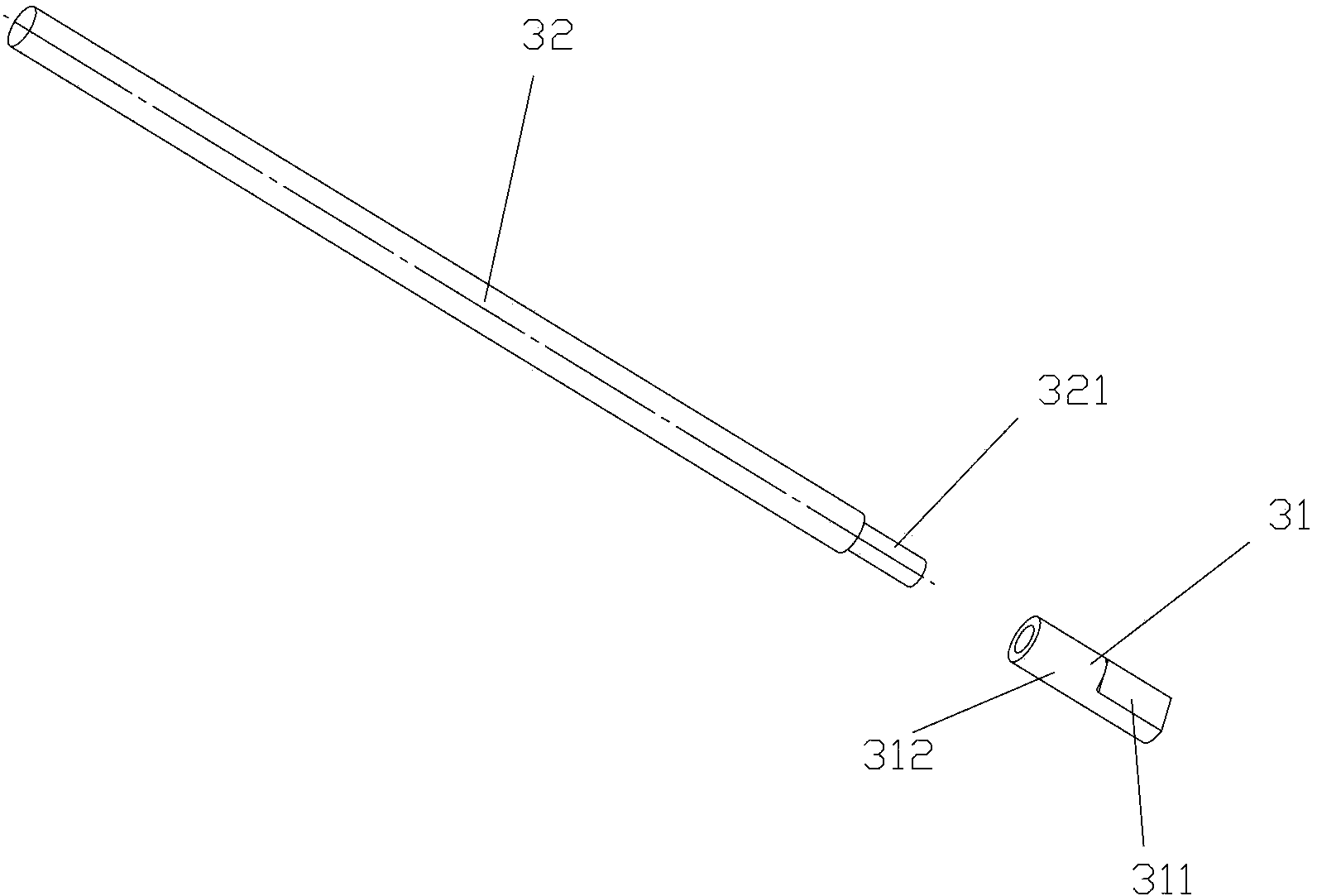

[0023] Examples, see Figure 1 to Figure 3 As shown, the lead-out structure of a relay that is convenient for the installation of a complete machine of the present invention includes:

[0024] Multiple relays lead to script body 1;

[0025] An insulating sheath 2 is provided with a plurality of jacks 21 respectively adapted to the script body of each relay, the insulating sheath 2 is plugged into the relay 10 as a whole, and the plurality of jacks of the insulating sheath 21 respectively cooperate with the corresponding relay to lead out the script body 1; and

[0026] A plurality of wire assemblies 3 with connecting terminals, one end of the connecting terminal 31 of the wire assembly is set as a flat structure 311, and the wire assembly is spot welded to the corresponding relay lead-out script body 1 through the flat structure 311 on the outside of the insulating sheath fixed.

[0027] The insulating sheath 2 is a single structure made of an insulating material with elastic proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com