Isothermal differential analysis method and isothermal differential analyzer of gas-solid reactions

A gas-solid reaction and analysis method technology, applied in the direction of chemical method analysis, analysis materials, instruments, etc., can solve problems such as unstoppable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

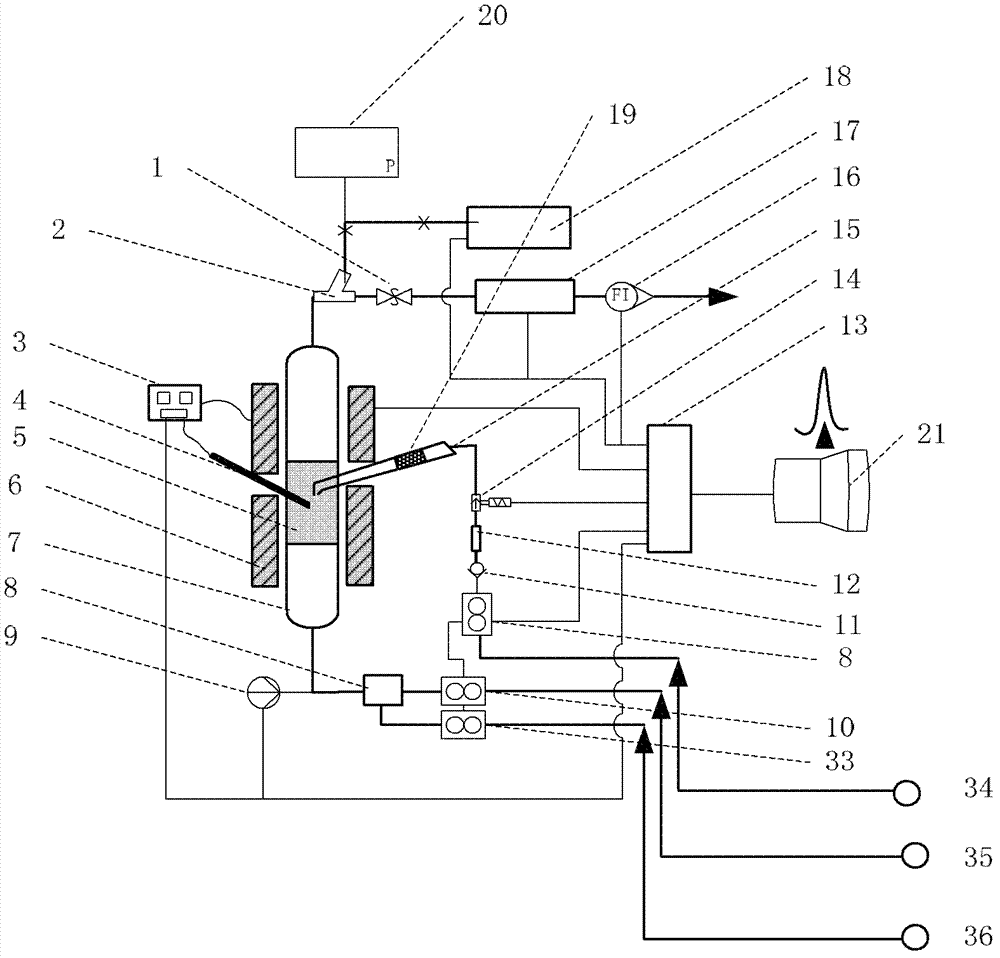

[0082] Example: A Micro Fluidized Bed Reactor for In Situ Cracking of Biomass Tar

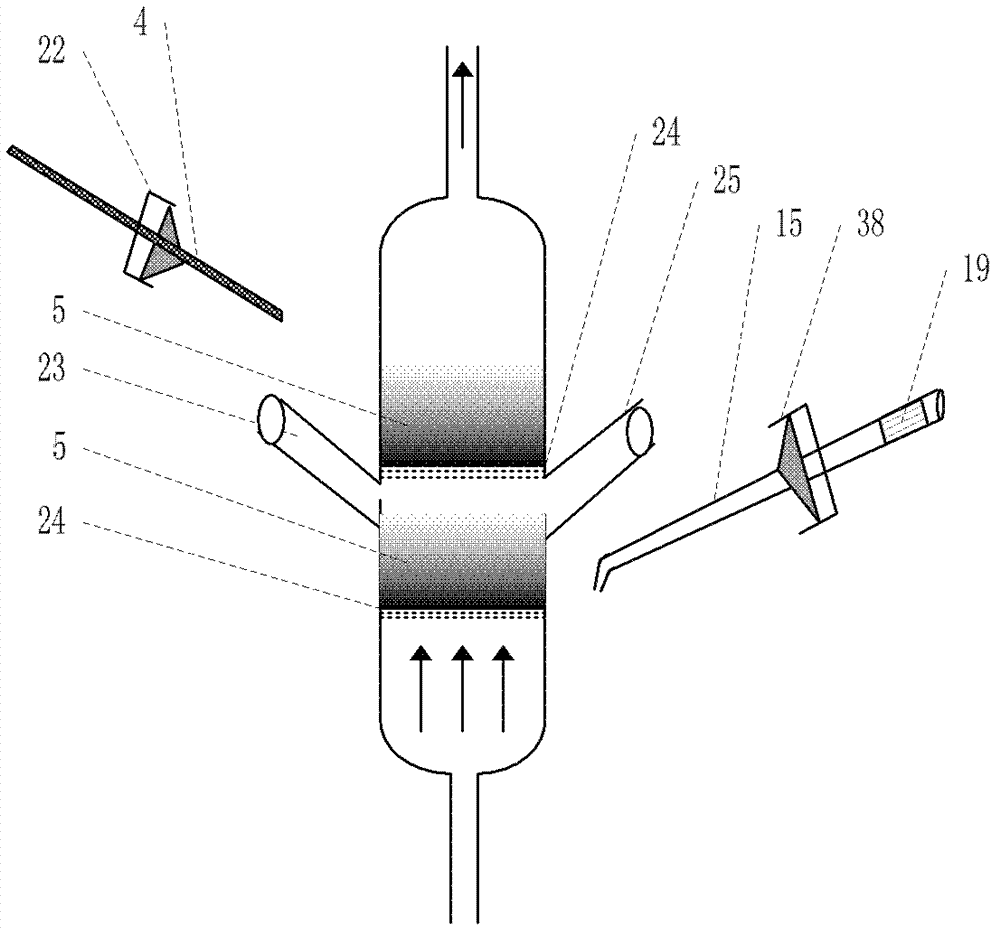

[0083] like Figure 5 As shown, the micro-fluidized bed 7 is a double-stage micro-fluidized bed, the lower side wall is provided with a sample tube casing to connect the sample tube, and the lower end inlet is provided with a liquid atomizing sampler 29, which can realize liquid On-line injection reaction analysis.

[0084] The pyrolysis reaction of biomass tar in the double-stage shallow fluidized bed can be carried out in two ways. The first way is to add the biomass material to the lower layer of the micro fluidized bed 7 through the transient pulse sampling system for reaction. The biomass material The tar produced in situ (lower layer of the micro fluidized bed) undergoes pyrolysis reaction of fluidized particles or other bed materials in the upper layer of the fluidized bed, so as to realize the pyrolysis reaction test of tar. Simultaneously, tar also can inject microfluidized bed 7 bot...

example

[0085]Example 2 Coal Pyrolysis Combustion Decoupling Reaction Micro Fluidized Twin-bed Reactor

[0086] like Image 6 As shown, the reaction was carried out in two microfluidized beds. Described micro-fluidized bed 7 is a two-stage micro-fluidized bed, and the side wall of the lower floor is connected with another single-stage micro-fluidized bed through a cyclone separator 30, and the side wall of the single-stage micro-fluidized bed is provided with a The sample tube casing is connected to the sample tube, and the upper part of the cyclone separator 30 has a gas outlet.

[0087] The fine coal particles enter a single-stage micro-fluidized bed through the transient pulse sample supply system for rapid pyrolysis reaction. After the cyclone separation (30), the gas product is detected by the gas purification and detection system to analyze the characteristics and kinetics of the rapid pyrolysis reaction; after the pyrolysis semi-coke passes through the cyclone separator 30, t...

example 3

[0088] Example three Micro fluidized bed reactor with diversion structure and solid sampler

[0089] like Figure 7 As shown, in order to adapt to the gas-solid reaction analysis of the change of solid form during the reaction process, a micro fluidized bed reactor with a built-in draft tube was developed. The micro-fluidized bed 7 is a single-stage micro-fluidized bed with a built-in guide tube, and the side wall is higher than the micro-electric furnace 6 places with a sample tube casing connected to the sample tube, and a solid gas distribution plate is connected above the side wall gas distribution plate. The collector 31 is connected with a liquid feed pipe at its lower part. One end of the liquid feed pipe extends above the gas distribution plate in the double-stage micro fluidized bed 7 , and the other end is placed in the preheating electric furnace 32 .

[0090] Taking a typical vapor deposition reaction as an example, the fine particle reactant is added into the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com