Car seat bump and creep durability testing machine

A technology for durability test and car seat, which is applied in the bump and creep durability test machine of car seat, test equipment, and the durability test field of bump and creep of car seat, which can solve the problems of waste of energy, high production cost and complex structure, etc. To achieve the effect of simple and reasonable structure design, lower production cost and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

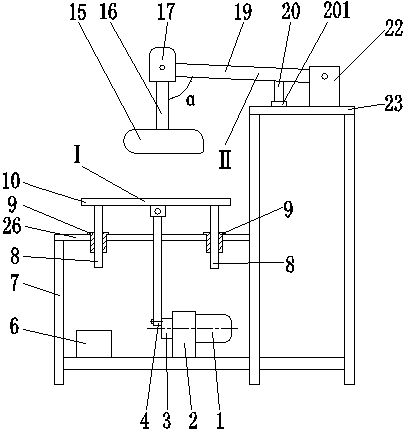

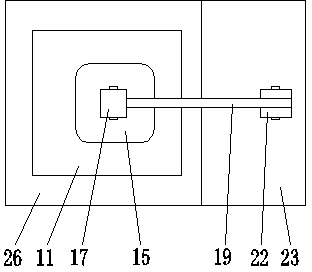

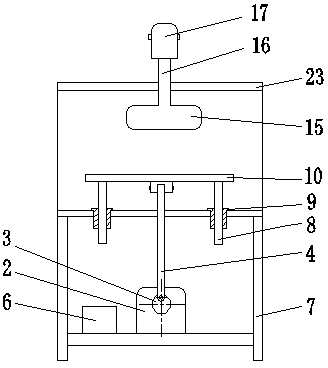

[0034] see figure 1 — Figure 6 , the embodiment of the present invention is mainly composed of a frame 7, an automatic lubricating oil injection machine 6, a jolting device I and a peristaltic device II; wherein: the jolting device I includes a speed regulating motor 1, a reduction box 2, an eccentric wheel 3, and a jolting connecting rod 4. Jolt connecting rod seat 25, jolt guide post 8, sliding bearing 9, jolt platen 10 and panel 26; peristaltic device II includes false hip 15, servo motor 16, peristaltic connecting rod 16, cantilever 19, support rod 20, cantilever The fixed seat 22 and the cantilever table 23; the automatic lubricating oil injection machine 6 is fixed on the frame 7; Rack 7.

[0035] The speed-regulating motor 1 in the bumping device I of the present invention is connected with the reduction box 2, the eccentric wheel 3 is installed on the reduction box 2, the bump connecting rod 4 is connected with the eccentric wheel 3 through the connecting pin 5; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com