A sp prestressed hollow slab with bolted embedded parts

A hollow slab and prestressed technology, which is applied in the direction of construction and building construction, can solve the problems of inability to realize reliable node connections between SP prestressed hollow slabs and steel structures, and achieve convenient and reliable assembly and adjustment, stable and reliable quality, and improved earthquake resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

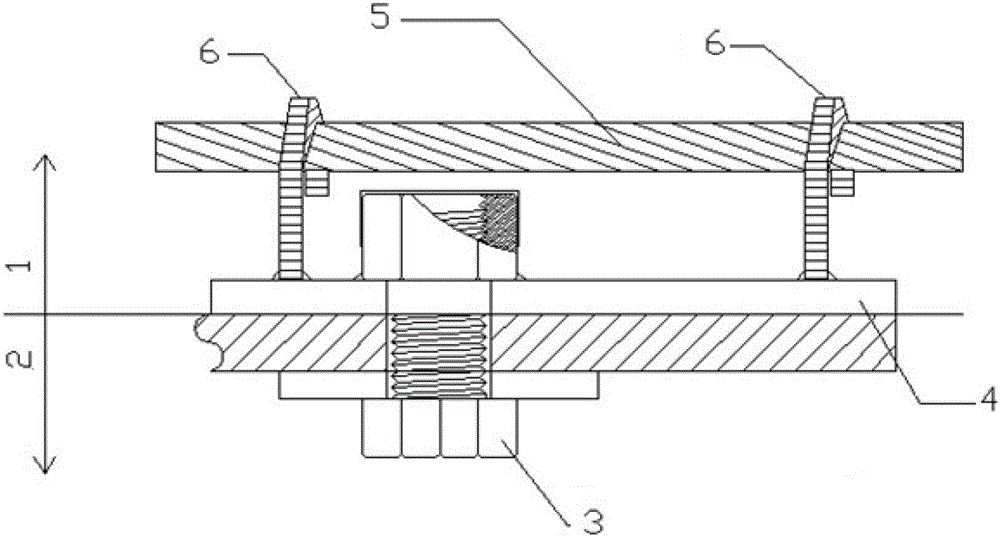

[0025] For the bolted embedded parts in Embodiment 1, refer to the performance of the connection node between the SP prestressed hollow slab and the steel structure in the National Standard Atlas, at least two embedded parts are prefabricated at one end of the SP slab, and M16 high-strength nuts 3 are used to secure the building The (wall) panel is connected to the steel structure 6 . The production of SP prestressed hollow slabs is the same as the original process, only welding nuts are added to the original embedded parts.

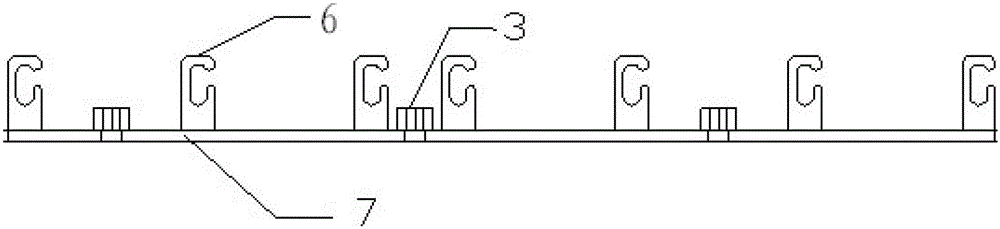

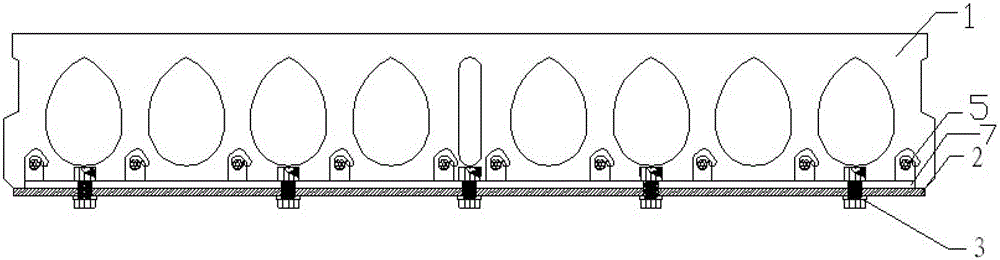

[0026] Based on the same principle, as figure 2 As shown, Embodiment 2 provides another SP prestressed hollow slab with bolted embedded parts, which includes a conjoined bolted embedded part 7, and the length of the connected bolted embedded part 7 is the same as that of the The width of the SP prestressed hollow slab is suitable, and the connected bolted embedded part 7 has the same number of buckle and anchor hooks as the main ribs of the SP prestres...

Embodiment 2

[0030] In Example 2, each steel strand (main reinforcement) of the SP prestressed hollow slab is connected to the steel beam through bolted embedded parts and high-strength nuts, effectively ensuring the integrity of the connection between the prestressed floor slab and the steel beam. Applying the bolted embedded parts of this case in the manufacture of prefabricated prestressed concrete slabs will improve the reliability of the connection between the main reinforcement of the slab and the beam, and expand the application field of prefabricated prestressed floor (wall) slabs.

[0031] Embodiment 2 A conjoined embedded part can be further placed at the end of the SP prestressed hollow slab with a length close to the width of the prefabricated slab, and the embedded parts buckle and anchor all the steel strands (main bars) in the concrete prestressed slab. The floor (wall) boards installed on site are connected with high-strength nuts in turn, so that all steel strands (main bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com