Heat-insulated degradable polypropylene foaming material and production method thereof

A foaming material, polypropylene technology, applied in the field of polymer composite materials, can solve the problems of poor expandability of polypropylene, difficulty in extrusion foaming, narrow processing window of extrusion foaming, etc., to achieve easy biodegradation and easy recycling The effect of utilization, not easy to break or crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

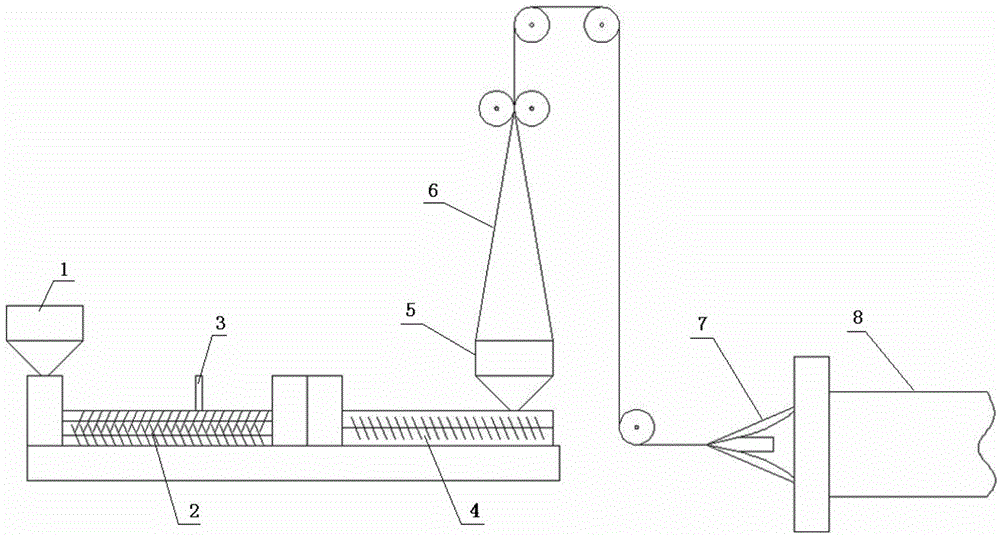

Method used

Image

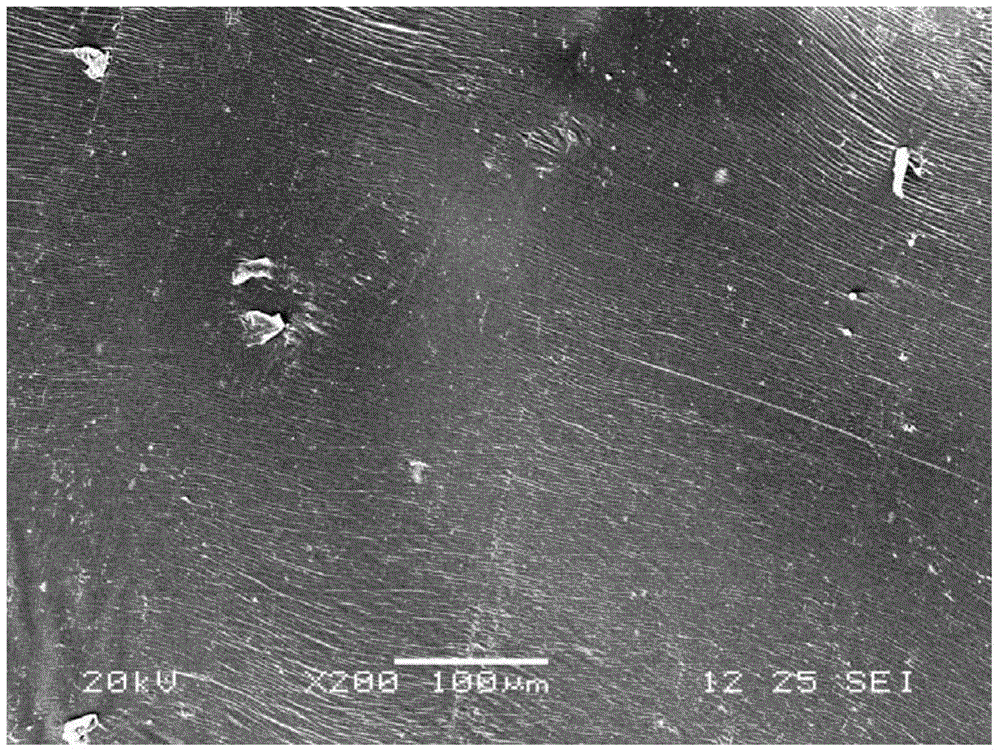

Examples

Embodiment 1

[0076] 1) Proportion the components and mass:

[0077] Long-chain branched polypropylene resin: 60 parts;

[0078] High crystalline homopolypropylene: 30 parts;

[0079] Chitosan nucleating agent: 1 part;

[0080] 1076 antioxidant: 0.5 parts;

[0081] Colorant: 1 part;

[0082] MB50-002 slip agent: 1 part;

[0083] Citric acid chemical foaming agent: 0.5 parts;

[0084] The components according to the mass ratio are uniformly dry mixed by a high-speed mixer;

[0085] 2) First-stage twin-screw extrusion: set the screw speed of the first-stage twin-screw extruder to 120r / min, the melt pressure to 17MPa, and the melt temperature to 185°C;

[0086] The first-stage twin-screw extruder includes three heating sections: feeding, melting and homogenizing. Among them, the heating temperature of the feeding section is set at 175°C, and the mixture formed after dry mixing is directly fed into the hopper, and the solid mixture is pushed into this section by the twin-screw for heatin...

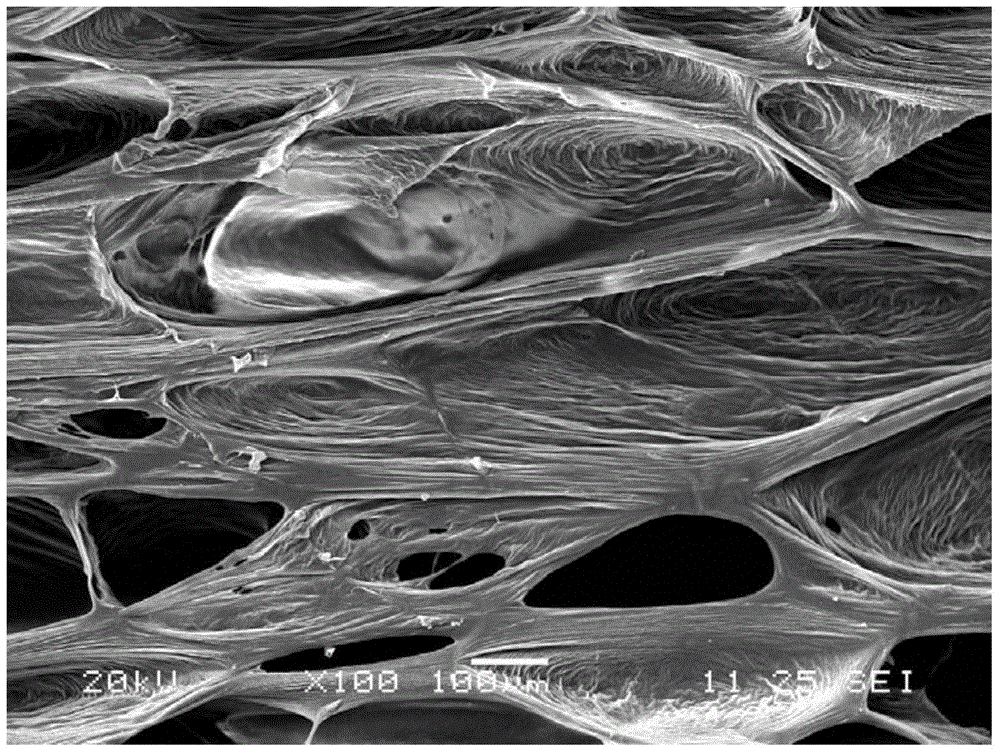

Embodiment 5

[0091] 1) Proportion the components and mass:

[0092] Long-chain branched polypropylene resin: 65 parts;

[0093] High crystalline homopolypropylene: 20 parts;

[0094] Linear low density polyethylene: 5 parts;

[0095] Talc nucleating agent: 2 parts;

[0096] 1076 antioxidant: 0.5 parts;

[0097] Colorant: 1 part;

[0098] MB50-002 slip agent: 1 part;

[0099] Citric acid chemical foaming agent: 0.5 parts;

[0100] The components according to the mass ratio are uniformly dry mixed by a high-speed mixer;

[0101] 2) First-stage twin-screw extrusion: set the screw speed of the first-stage twin-screw extruder to 20r / min, the melt pressure to 17MPa, and the melt temperature to 185°C;

[0102] The first-stage twin-screw extruder includes three heating sections: feeding, melting and homogenizing. Among them, the heating temperature of the feeding section is set at 175°C, and the mixture formed after dry mixing is directly fed into the hopper, and the solid mixture is pushe...

Embodiment 9

[0107] 1) Proportion the components and mass:

[0108] Long-chain branched polypropylene resin: 70 parts;

[0109] High crystalline homopolypropylene: 10 parts;

[0110] Ethylene-vinyl alcohol copolymer resin: 10 parts;

[0111] Calcium carbonate nucleating agent: 3 parts;

[0112] 1010 Antioxidant: 0.5 parts;

[0113] Colorant: 1 part;

[0114] EDS slip agent: 1 part;

[0115] Azodicarbonamide chemical blowing agent: 0.5 part;

[0116] The components according to the mass ratio are uniformly dry mixed by a high-speed mixer;

[0117] 2) The first-stage twin-screw extrusion: set the screw speed of the first-stage twin-screw extruder to 20r / min, the melt pressure to 16MPa, and the melt temperature to 185°C;

[0118] The first-stage twin-screw extruder includes three heating sections: feeding, melting and homogenizing. Among them, the heating temperature of the feeding section is set at 170°C, and the mixture formed after dry mixing is directly fed into the hopper, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com