Front wall body center channel safety airbag ECU (electronic control unit) fixing bracket welding assembly

An airbag and fixing bracket technology, which is applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, transportation and packaging, etc., can solve problems such as inability to install airbag ECU, achieve light weight, strong plastic deformation and yield strength, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

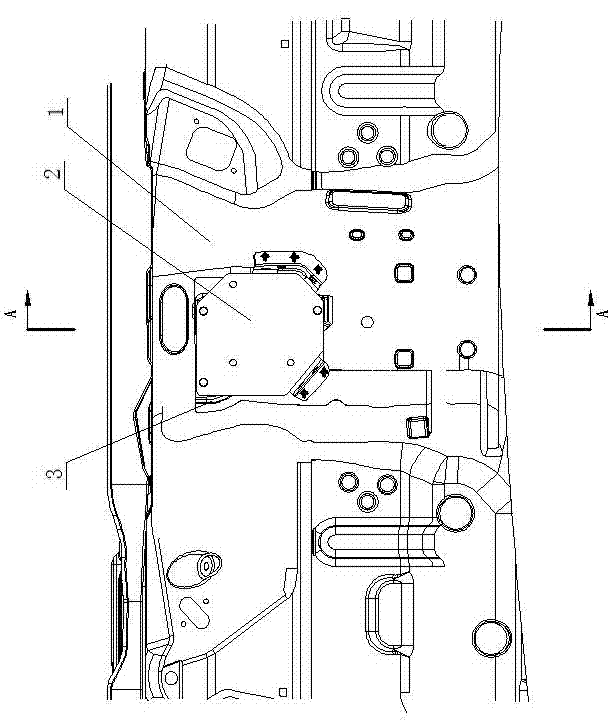

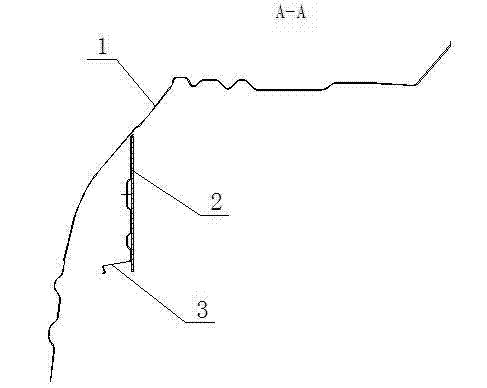

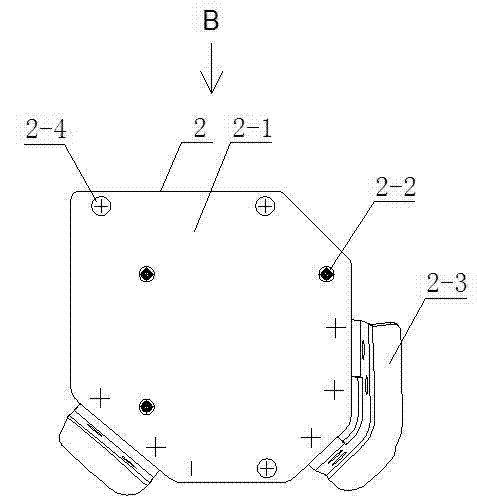

[0016] Such as Figure 1-5 As shown, the present invention comprises a cowl body 1, a transmission mounting plate assembly 3 is welded on the cowl body 1, and an airbag ECU fixing bracket 2 is arranged on the transmission mounting plate assembly 3. The airbag ECU fixing bracket 2 includes an airbag ECU mounting plate 2-1 and two welding feet 2-3, the airbag ECU mounting plate 2-1 is horizontally arranged above the transmission mounting plate assembly 3, and the airbag ECU mounting plate 2 -1 is provided with three bolt mounting holes 2-4 and three ECU bolt holes 2-2, and the airbag ECU mounting plate 2-1 is connected with the transmission mounting plate assembly 3 by setting bolts in the bolt mounting holes 2-4, Two welding legs 2-3 are welded with the cowl body 1 respectively, and nuts 2-5 are respectively welded under the airbag ECU mounting plate 2-1 at each ECU bolt hole 2-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com