Display cabinet with back condenser

A technology for condensers and display cabinets, which is applied in the field of display cabinet manufacturing. It can solve the problems of insufficient condenser area, easy contact with walls, and low heat dissipation efficiency, so as to prevent direct contact with the condenser and reduce the risk of being scalded , use safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

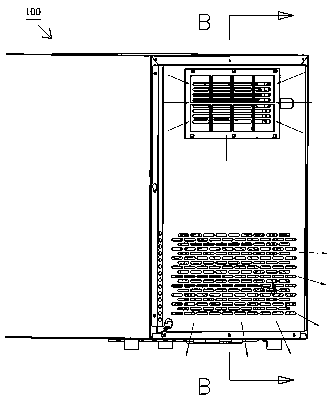

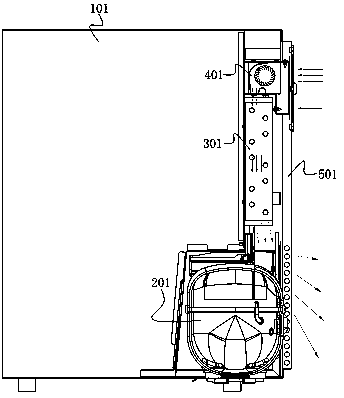

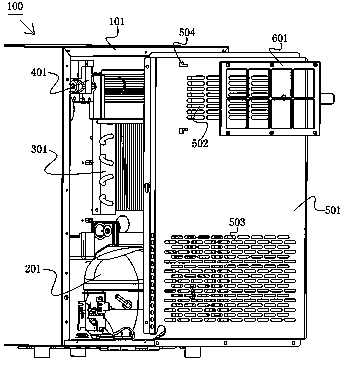

[0037] Such as Figure 1 to Figure 4 As shown, a display cabinet 100 with a back condenser of the present invention includes a cabinet body 101, a compressor compartment 201, a condenser 301 and a cooling fan 401, and the compressor compartment 201, the condenser 301 and the cooling fan 401 are arranged from bottom to top Inside the cabinet body 101 is provided. Wherein, in order to effectively reduce the structural size of the compressor chamber 201 and increase the usable effective volume in the cabinet 101 , the condenser 301 and the cooling fan 401 are both arranged on the back of the cabinet 101 . At the same time, in order to protect the condenser 301 and the cooling fan 401 from being damaged, and to prevent the user from directly touching the condenser 301 and reducing the risk of being scalded, the cabinet 101 is provided with a cover plate 501 to cover the compressor compartment 201, the condenser 301 and the cooling fan. 401 covered.

[0038] Such as image 3 , ...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that in this embodiment, the first air inlet and the first air outlet are both open openings, which can reduce wind resistance compared with dense air inlets and air outlets, so that The air flows more smoothly, which in turn improves the cooling efficiency.

[0047] Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com