Flexible Mounting Fixtures for Miniature Mode Switching Ultrasonic Motors

A mode conversion, ultrasonic motor technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as the difficulty of fixed installation of ultrasonic motors, and achieve low impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

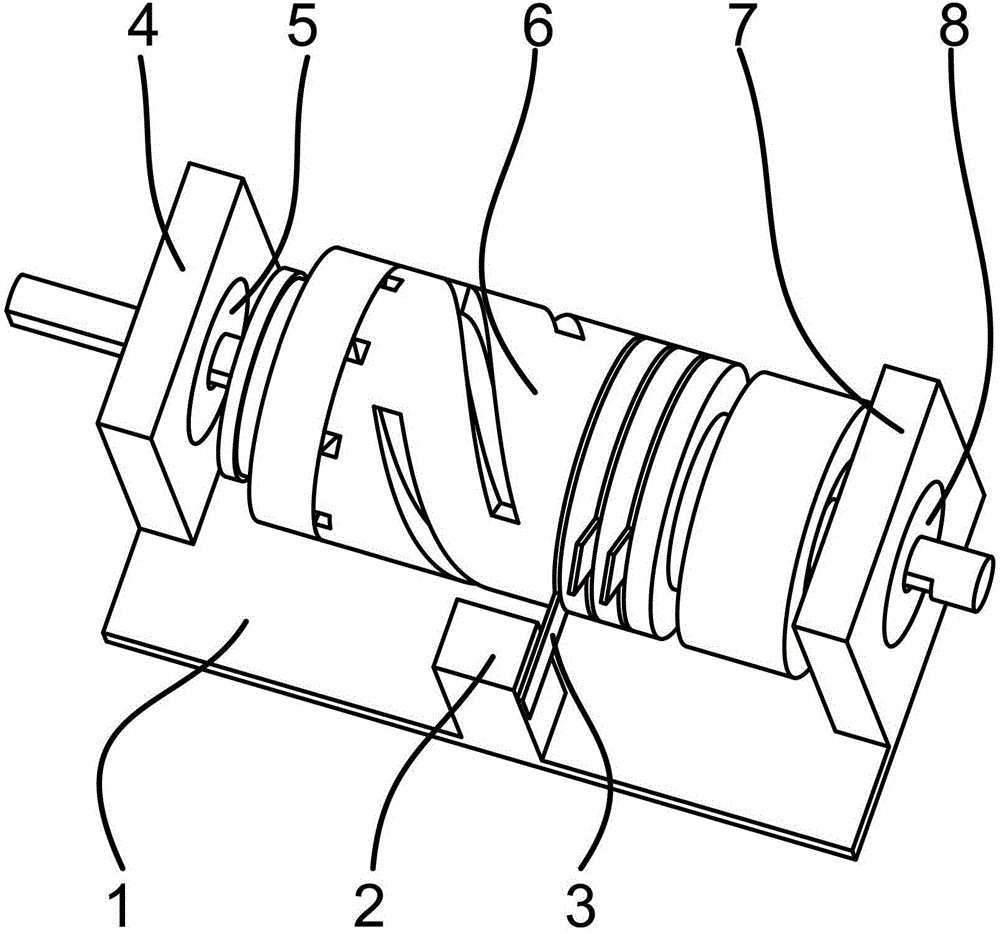

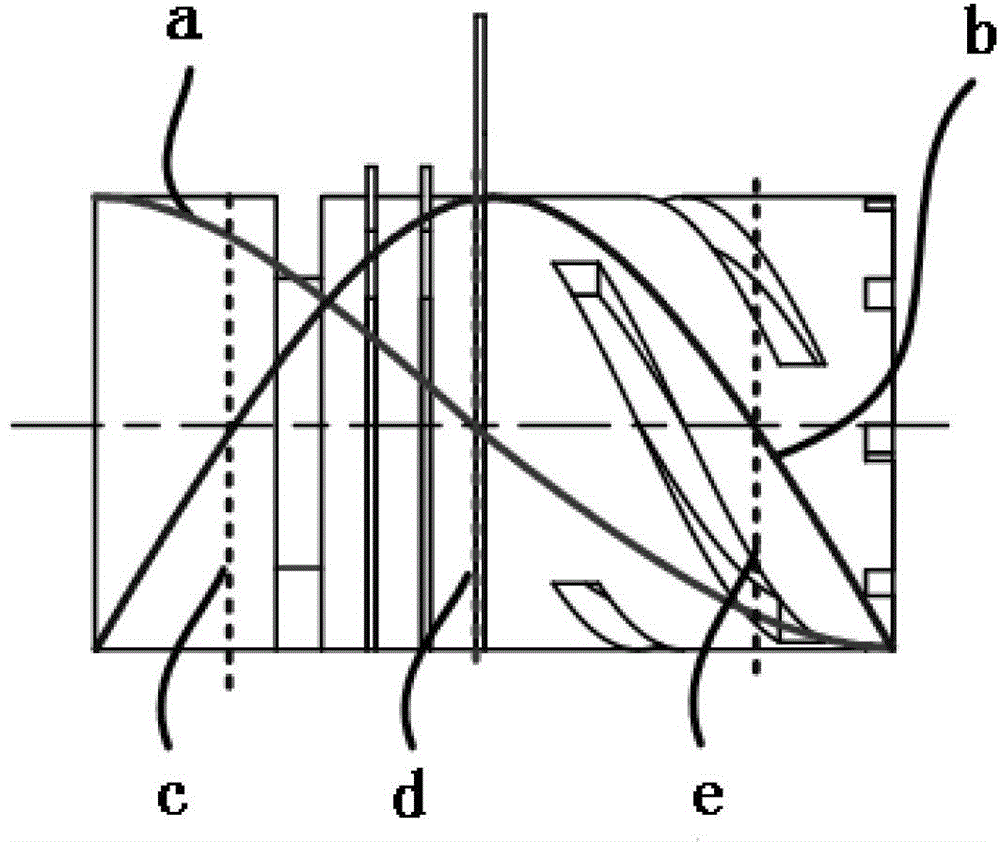

[0016] Such as figure 1 and figure 2 As shown, the flexible installation and fixing device of the miniature mode conversion ultrasonic motor according to the present invention is used for positioning and installation of the miniature mode conversion ultrasonic motor 6, and the miniature mode conversion ultrasonic motor 6 includes a rotor and a stator assembly. The flexible installation and fixing device of the present invention includes a motor base 1, the rotor is positioned and supported on the motor base 1 through a rotating shaft, the stator assembly is configured with a flexible installation piece 3, and the base of the flexible installation piece 3 is a ring-shaped thin metal sheet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com