Industrial Frequency Switching Type Hydraulic Coupler

A hydraulic coupling and industrial frequency switching technology, which is applied to fluid transmission devices, components with teeth, belts/chains/gears, etc., can solve the problems of increasing power consumption and electricity cost, and achieve additional Electricity consumption and the effect of increasing electricity cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

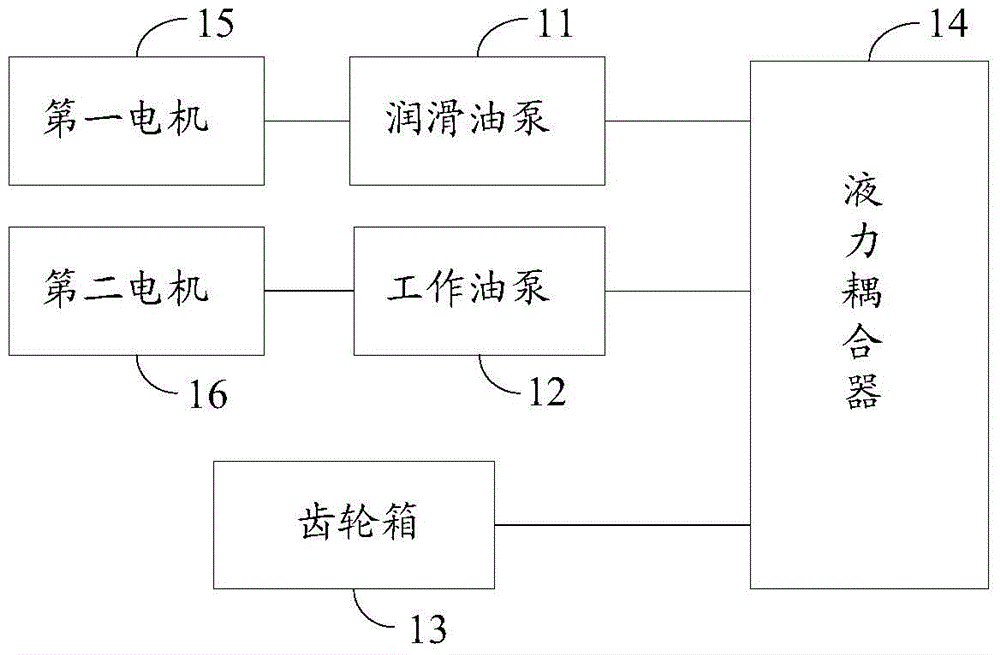

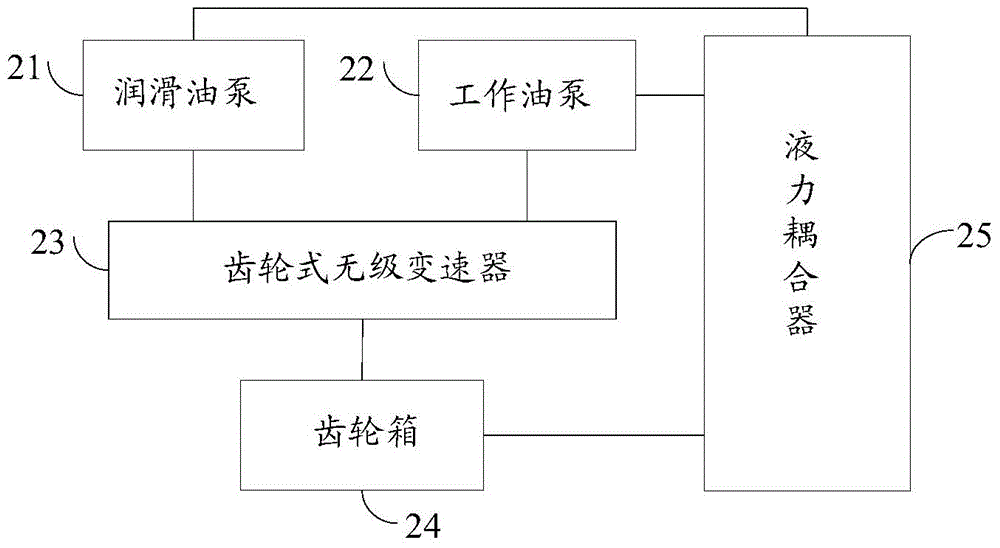

[0039] see figure 2 , figure 2 It is a structural diagram of an industrial frequency switching hydraulic coupling provided by an embodiment of the present invention. Such as figure 2 As shown, the industrial frequency conversion switching hydraulic coupling provided by the embodiment of the present invention includes:

[0040] Lubricating oil pump 21, working oil pump 22, gear type continuously variable transmission 23, gear box 24, hydraulic coupling 25;

[0041] The output shaft of the gear type continuously variable transmission 23 is respectively connected with the lubricating oil pump 21 and the working oil pump 22;

[0042] The output shaft of the gear box 24 is connected with the input shaft of the gear type continuously variable transmission 23;

[0043] The output shaft of the gear box 24 is connected with the input shaft of the hydraulic coupling 25;

[0044] The lubricating oil pump 21 and the working oil pump 22 are respectively connected to the hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com