Method and device for removing water and heavy hydrocarbons from shale gas

A technology for removing heavy hydrocarbons and shale gas, which is applied in the fields of gas fuel, processing of hydrocarbon oil, petroleum industry, etc. The problem of large changes in composition can achieve the effects of reduced energy consumption, easy operation and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

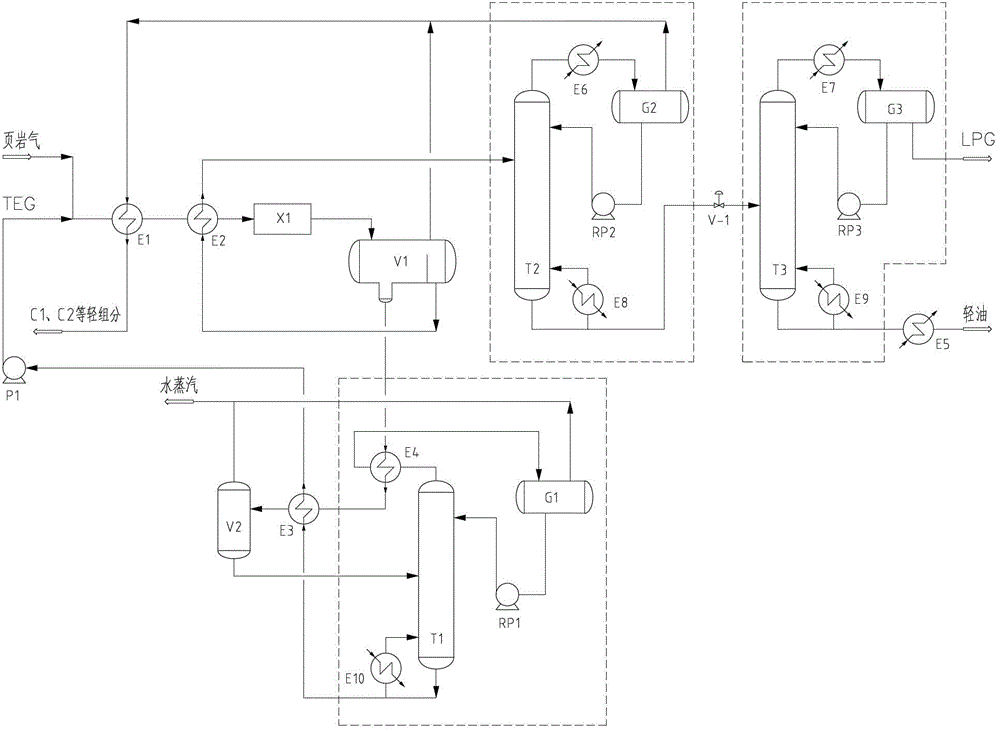

[0041] The method of the present invention includes two parts: a dehydration and heavy hydrocarbon removal process and a heavy hydrocarbon treatment process; the dehydration and heavy hydrocarbon removal process includes using triethylene glycol to remove moisture and heavy hydrocarbons in shale gas at low temperature in the three-phase separator V1, absorbing the moisture The triethylene glycol is regenerated in the regeneration tower T1; the heavy hydrocarbon treatment process includes the heavy components above C3 in the shale gas, and the remaining light components such as C1 and C2 are separated in the deethanizer T2, and the heavy components above C3 Enter the rectification tower T3 to be separated into LPG and light oil.

[0042] The technical process of the shale gas dehydration and deheavy hydrocarbon method provided by the invention is as follows, referring to the appended figure 1 ,

[0043] In the dehydration and heavy hydrocarbon removal process, the regenerated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com