Biomass carbonization technology and equipment

A biomass and equipment technology, applied in the field of biomass carbonization methods and equipment, to achieve the effect of solving slow heating and fast production, making up for the impact, and improving carbonization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

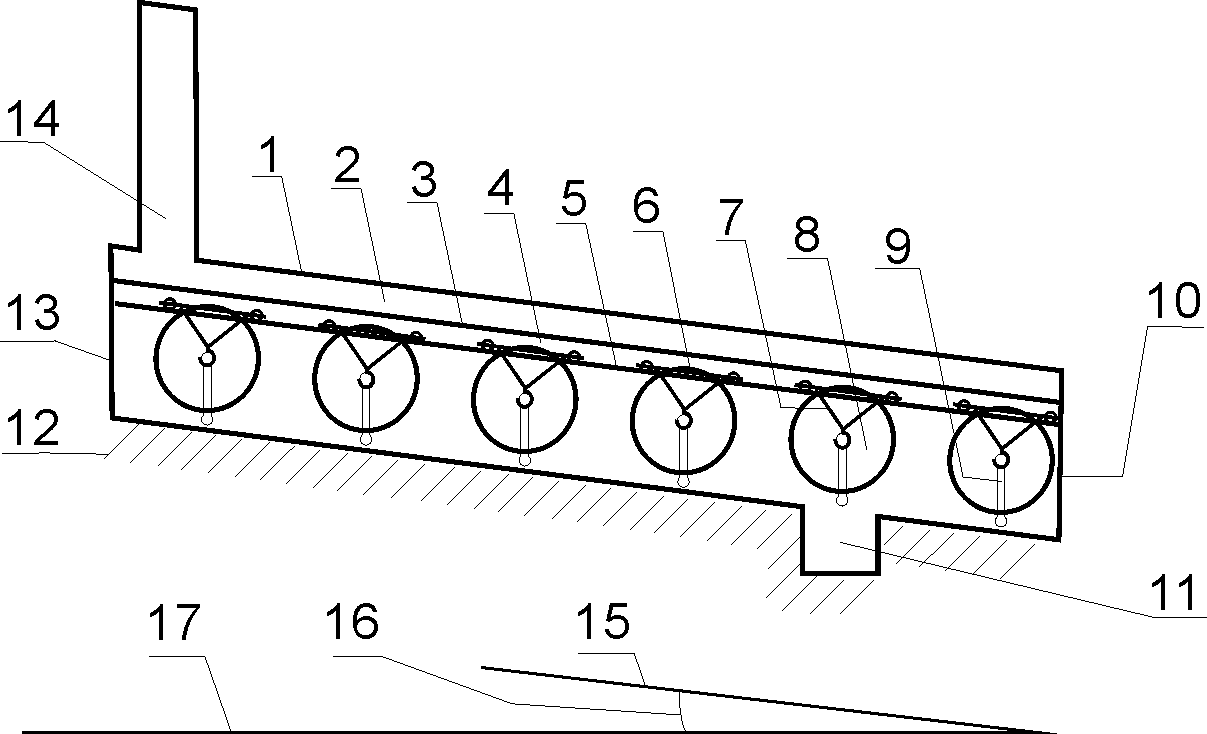

[0031] 1. Component composition and connection relationship

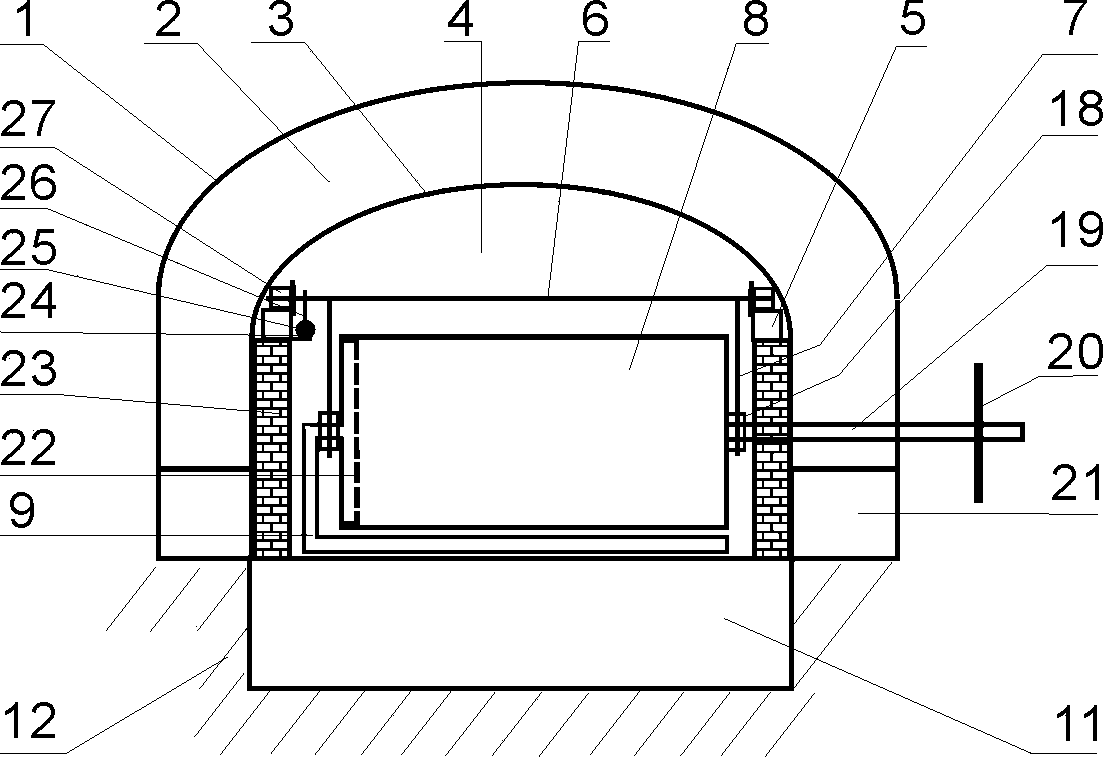

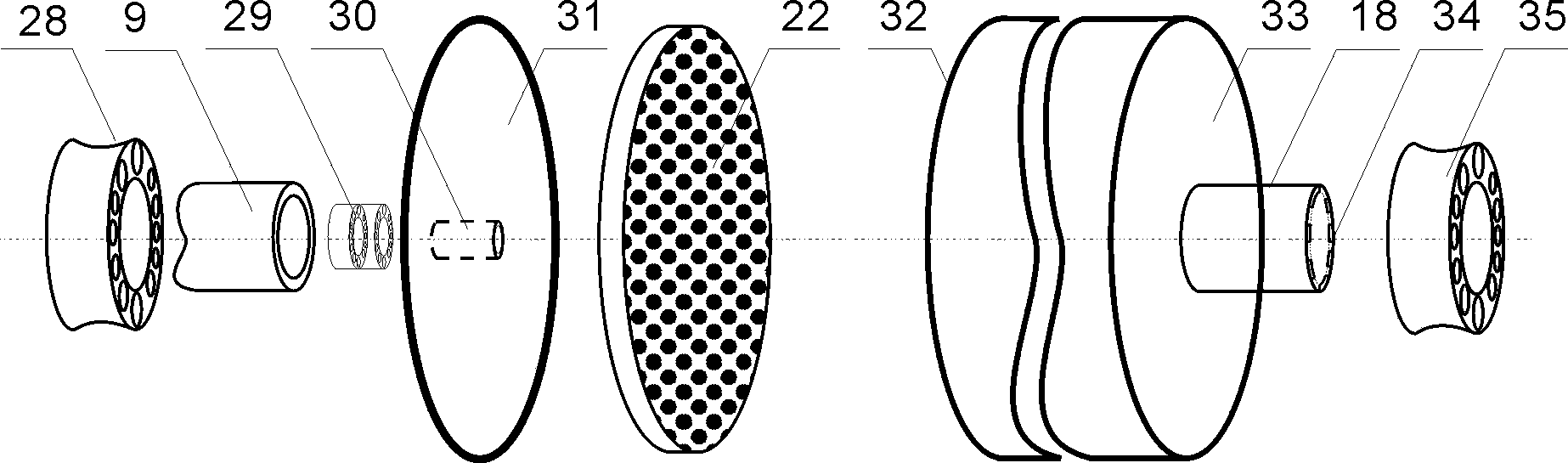

[0032] Such as Figure 1-5 As shown, a biomass carbonization equipment includes a carbonization furnace, a retort barrel 8, a guide rail 5, a guide rail car 6, and a trolley required for the retort barrel to enter and exit the carbonization furnace. A slope 16 of 5-10 degrees is formed between the extension direction 15 of the carbonization furnace body and the ground plane 17 . The retort barrel 8 moves in the carbonization furnace through two guide rails 5 fixed on the inner wall of the carbonization furnace and the guide rail car 6 moving on the guide rails under the action of gravity; the stay of the retort barrel 8 on the guide rail 5 is controlled by a The movable gear rod 25 is controlled, and the rotation of the retort barrel is realized by a transmission rod 19 passing through the furnace wall.

[0033] The carbonization furnace is composed of an outer furnace wall 1, an inner furnace wall 3, a combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com