Method for preparing globular porous calcium carbonate granules

A porous calcium carbonate, particle technology, applied in calcium carbonate/strontium/barium, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of large size distribution of calcium carbonate powder, harsh and complex preparation conditions, and poor uniformity and other problems, to achieve the effects of mild and controllable preparation conditions, good biocompatibility and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Arginine solution, 60 mM calcium chloride solution, and 60 mM sodium carbonate solution were respectively prepared with a mass fraction of 2%. First, 40 mL of arginine solution and sodium carbonate solution were mixed at a volume of 1:1 to form Mix the solution; then, under the condition of stirring at 600 rpm, add the mixed solution of sodium carbonate dropwise to 200 mL of calcium chloride solution through a constant flow pump; continue vigorously stirring for 15 min after the addition is completed; wait for the reaction After completion, centrifuge at 3000 rpm for 5 min to collect the particle precipitate, and wash it several times with absolute ethanol and deionized water; finally, put it in a constant temperature oven at 60°C and dry it overnight to collect the nano-calcium carbonate particle powder.

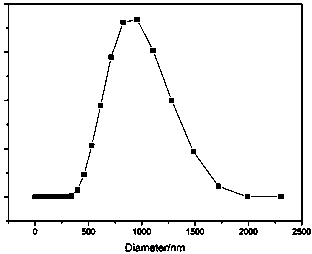

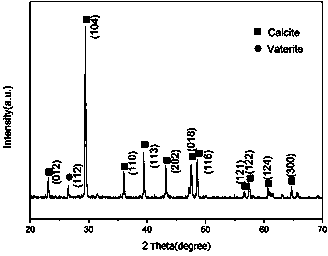

[0031] The nano-calcium carbonate particle powder is composed of nano-calcium carbonate with a diameter of 150-250 nm, has a spherical shape, has a loose porous struc...

Embodiment 2

[0034] Arginine solution, 40 mM calcium nitrate solution, and 40 mM sodium carbonate solution were respectively prepared with a mass fraction of 2%; first, 40 mL of arginine solution and sodium carbonate solution were mixed at a volume of 1:1 to form a mixed solution; then, under the condition of stirring at 300rpm, the sodium carbonate mixed solution was added dropwise into 200 mL of calcium chloride solution through a constant flow pump; after the dropwise addition was completed, continue to stir vigorously for 15 min; after the reaction was completed, The pellet was collected by centrifugation at 4000 rpm for 3 min, and washed several times with absolute ethanol and deionized water; finally, it was dried overnight in a constant temperature oven at 60°C to collect nano calcium carbonate particle powder.

Embodiment 3

[0036] Arginine solution, 60 mM calcium nitrate solution, and 60 mM sodium carbonate solution with a mass fraction of 1% were respectively prepared; first, 40 mL of arginine solution and sodium carbonate solution were mixed at a volume of 1:1 to form a mixed solution; then, under the condition of stirring at 500 rpm, the sodium carbonate mixed solution was added dropwise into 200 mL of calcium chloride solution through a constant flow pump; after the addition was completed, continue to stir vigorously for 15 min; after the reaction was completed Finally, the pellet was collected by centrifugation at 3500 rpm for 5 min, and washed several times with absolute ethanol and deionized water; finally, it was dried overnight in a constant temperature oven at 60°C to collect nano calcium carbonate particle powder.

[0037] The nano-calcium carbonate particle powder that embodiment 2 and 3 obtains all has the technical parameter identical with the nano-calcium carbonate particle powder t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com