Chained ditcher

A ditching machine and chain-type technology, applied in the direction of digging/covering ditches, planting methods, earth movers/shovels, etc., can solve the difficulty of repairing and replacing earth shovels, the inability to automate ditching, and the inconvenience of installation, etc. problems, to achieve the effect of improving ditching efficiency, simple structure, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

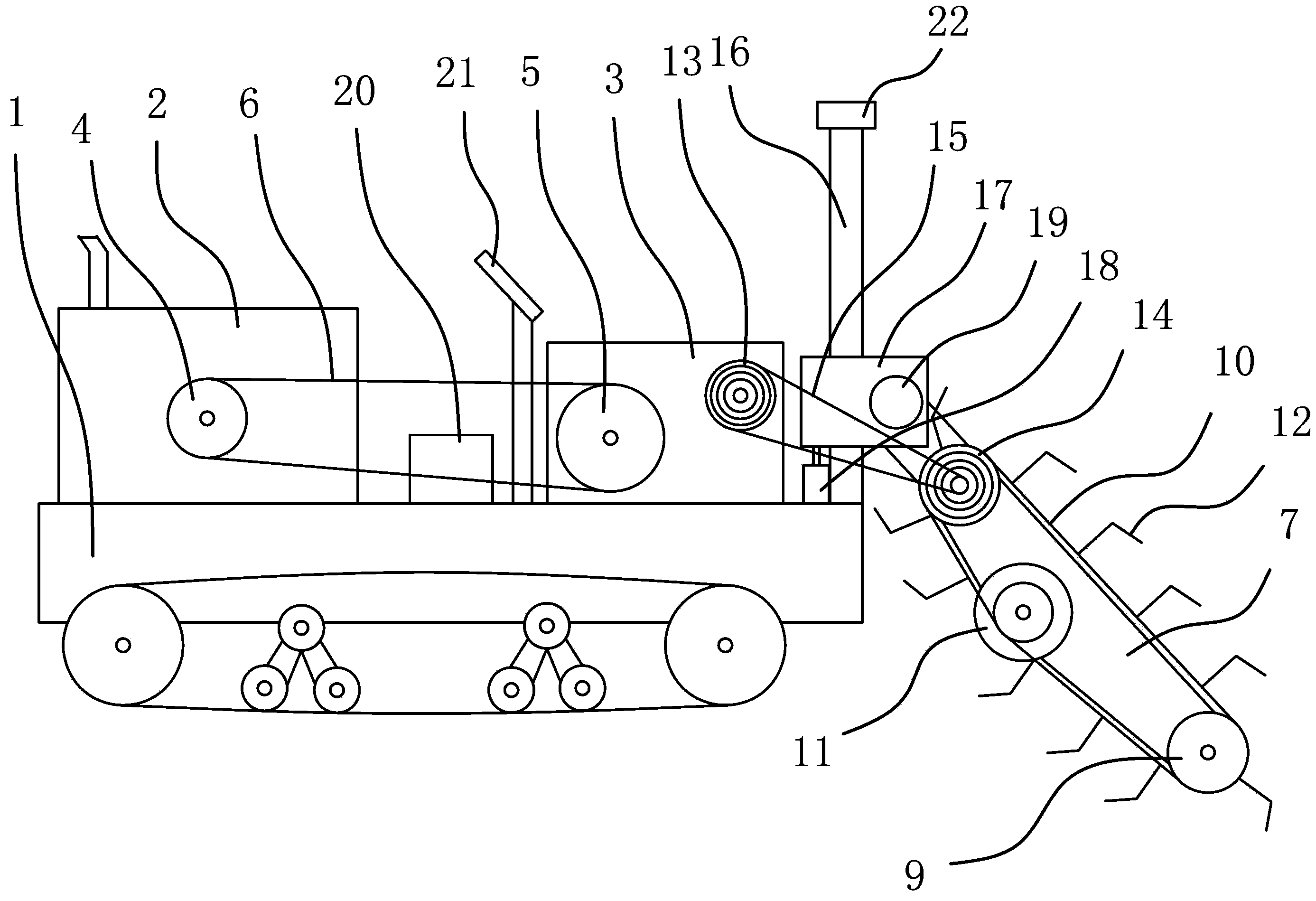

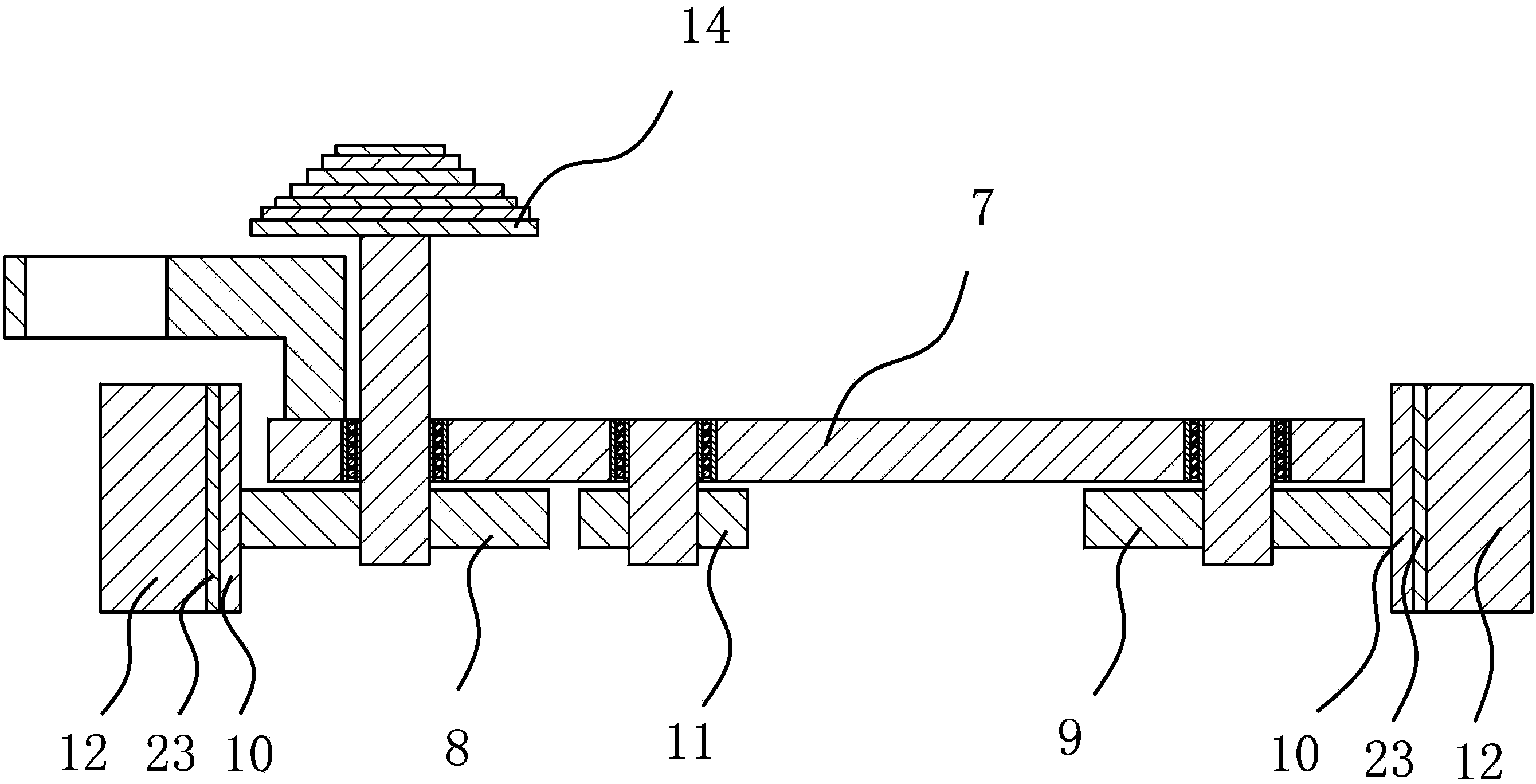

[0027] Such as figure 1 Shown, a kind of chain ditching machine comprises body 1, is fixed with diesel engine 2 and speed reducer 3 on body 1, and diesel engine 2 has output shaft, and belt pulley-4 is fixed on the output shaft, and speed reducer 3 has power input shaft and The power output shaft and the power input shaft are fixed with pulley 2 5, pulley 1 4 and pulley 2 5 are in the same plane, and pulley 1 4 and pulley 2 5 are connected through V-belt 6; figure 2As shown, one side of the body 1 is provided with a ditching device capable of digging ditches to the land, including a support 7, a driving sprocket 8, a driven sprocket 9, a chain 10, a stirring wheel 11 and some chain knives 12, The driving sprocket 8 is axially positioned on one end of the support 7 through the rotating shaft one, the driven sprocket 9 is axially positioned on the other end of the support 7 through the rotating shaft two, and the stirring wheel 11 is axially positioned on the support 7 through ...

Embodiment 2

[0037] The structure and principle of this embodiment are basically the same as the first embodiment, the difference is: in the first embodiment, the lifting and positioning mechanism is a cylinder 18; and in the second embodiment, the lifting and positioning mechanism is a push rod motor , the push rod motor is vertically arranged, and the push rod motor is fixed on the body 1 by screws, the push rod of the push rod motor is vertically upward, and the upper end of the push rod is fixed on the lower side of the slide block 17. The push rod motor is connected to the PLC programmable controller 20 on the body 1 through a line, and the push rod motor is started, and the push rod of the push rod motor can be stretched up and down, thereby pushing the sliding block 17 up and down along the column 16, and finally the sliding block 17 moves up and down with the bracket 7 on one side of the body 1; when the bracket 7 moves to a reasonable height, turn off the push rod motor to position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com