Four-phase double-sided flat plate transverse field permanent magnet motor

A technology of transverse magnetic field and permanent magnet motor, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve problems such as the difficulty of winding stator armature, achieve convenient processing and assembly, simplify winding, reduce poles The effect of intermittent magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

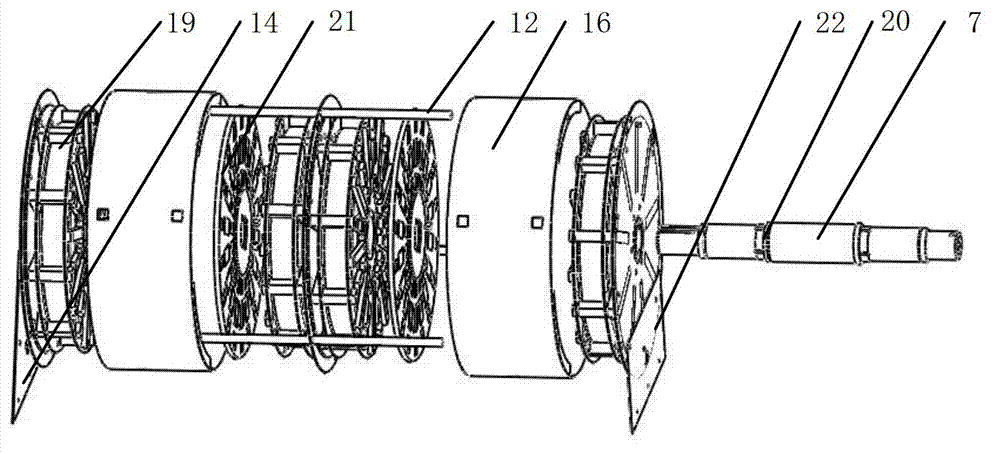

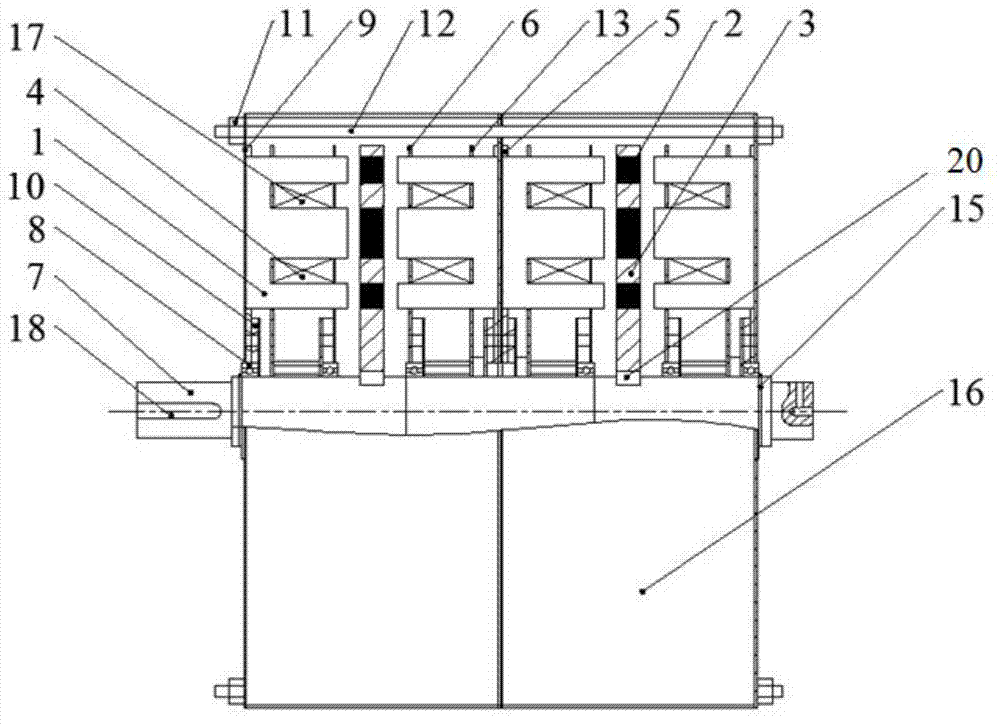

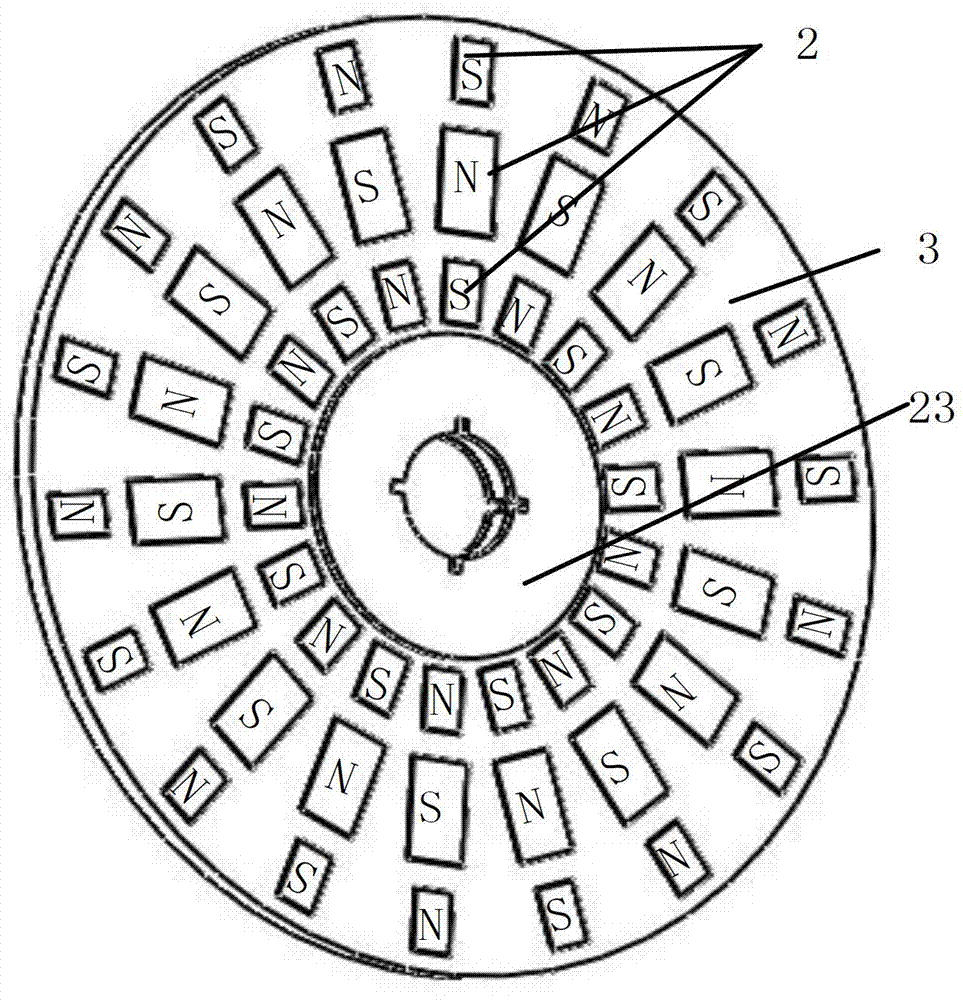

[0017] The following examples refer to Figure 1~5 .

[0018] The four-phase double-sided plate type transverse magnetic field permanent magnet motor of the present invention includes E-shaped silicon steel sheet 1, permanent magnet 2, permanent magnet panel 3, inner armature winding 4, magnetic pole fixing plate 5, crimping plate 6, motor shaft 7, Bearing 8 and positioning plate 9. It also includes a bearing mounting ring 10, a nut 11 for a lead screw, a lead screw 12, a pay-off plate 13, a left stator bracket 14, a shaft snap ring 15, a casing 16, an outer armature winding 17, a stator 19, a rotor 21, a right Side stator support 22 , rotor strength reinforcement rings 23 , 27 - magnetic strip 27 and bearing retaining ring 30 .

[0019] The four-phase double-sided plate type transverse magnetic field permanent magnet motor of the present invention is composed of four stators 19 and two rotors 21 . The left and right sides of each rotor 21 correspond to a stator 19 , so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com